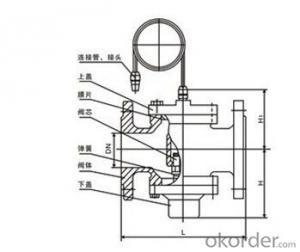

ASZK Self-operated flow control valve

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

A, product overview

ZLF (ZL - 4 m) series for flow control valve (self balancing valve) is a kind of intuitive easy flow adjusting control device, the network application of the valve can be directly set according to the design flow, the valve can be used in water, automatic eliminate the remainder of the pipeline pressure head and flow caused by pressure fluctuation is poor, no matter what the system pressure change all the set flow rate unchanged, the valve is finished at one time, these features make the network flow control to the net work for simple flow distribution, effectively solving the hydraulic imbalance between the network.

B,Technical parameters

1, medium temperature 0-150 ℃

2, work pressure differential 20-600 kpa

C, the performance and features

1, can be set according to the requirements of design or the actual flow rate, the system can automatically eliminate the differential pressure fluctuation, the flow rate unchanged;

2, to overcome the system cold hot uneven phenomenon, improve the quality of heating (cooling);

3, completely solve the proximal differential pressure big, distal small pressure difference;

4, reduce system circulating water, reduce the system resistance;

5, reducing design effort, do not need to complex pipe network hydraulic balance calculation;

6, decrease the difficulty of the network turn complex net work is simplified to a simple flow distribution;

7, be exempted from the flow of heat pipe heat source switch more redistribution work;

8, flow display values are based on random calibration test bench, flow (m3 / h).

- Q: the rest are hot, the living room outside all the heating pipe valve closed, the living room heating is still not hot, after the water for a while hot, and cold

- There is gas, causing water not to cycle, give up on the cure! Are you single family control?Single family control, the general bedroom and living room is not all the way, the living room, this way, the vent valve in the toilet, I was on the road in the balcony! The bleeder valve, is made of copper tube in the device above two, as long as can step in his place, the bleeder valve with a small angle, feet above a needle, with a needle to drill a well, there is a long time not float, a gas exhaust out that leads to water circulation,Why do you put a little while, the water is hot, a little cooler, the water does not cycle, is dead water, can not cool it?I am building plumbing, believe me, yes, these are some common problems, especially on the top floor!

- Q: So how does the valve turn on?

- The handle of the valve is opened along the pipe and perpendicular to the pipe

- Q: such as gate valve, three way plug valve

- The lower part of the pressure gauge installed water pipe, there are water, avoid high temperature, medium pressure gauge contact directly cause damage, so regular cleaning, in order to avoid congestion, three way plug function is used for flushing, please see "how to operate them.".

- Q: What kind of valve is it? How do you see the status of the switch?

- This is a ball valve, that is, usually said cut-off valve, to determine the switch state is carefully look at, there is a switch on the status of the arrow, you will understand.

- Q: Where is the valve used?

- Oil and gas pipelines, gas stations, gas stations, petrochemical plants, water works,

- Q: How much is the 150LB of the valve?

- 150Lb=2.0MPa=20 kg.Valve (Famen) is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure.Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications.

- Q: How big valves are used in a DN159 pipe?

- Nominal diameter DN150 corresponds to the outer diameter of De159To say DN159 is wrong, because DN is the nominal diameter (diameter in the middle of the tube wall)De159 refers to the outside diameter (outside the diameter of the wall)DN39 should be DN32. Nominal diameter 32, outer diameter 39.

- Q: Yongde jiekelong valves and valves of the good faith

- Interior decoration is the most cost-effective brand, switches, sockets, Zhejiang, Yongkang, France and Germany electrical appliances. Plumbing valve, Zhejiang, Yongde, Yongkang letter. Bathroom accessories Fujian Nanan Jomoo bathroom.

- Q: What is the diameter of a general pipe valve?

- In fact, the essence of the problem is the corresponding relationship between the nominal diameter and other dimensioning methods. Valves are generally marked with nominal diameter (DN***), such as DN150, DN100 and so on. There are many kinds of marking methods for pipes, such as outer diameter, inch inch, nominal diameter, etc.. Only when the other dimensioning is converted to nominal diameter, the valve and the pipe correspond to each other.

- Q: Is there any difference between the valve and the water valve?

- Oil valve with water valve is that the oil valve is over the oil, and the valve is over water, the type of fluid is not the same.Valve (Famen) is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure.Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications. Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow. The valve according to the material is divided into cast iron valves, cast steel valves, stainless steel valves (201, 304, 316), chrome molybdenum steel, chromium molybdenum vanadium steel valves, valve, dual phase steel valves, plastic valves, non-standard customized valve material etc..

Send your message to us

ASZK Self-operated flow control valve

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords