ASTM A53/A106/ API 5L GrB Sch40 Seamless Galvanized Carbon Steel Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Seamless Pipe ASTM A106/53:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2.Main Features of the Seamless Pipe ASTM A106/53:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3.Seamless Pipe ASTM A106/53 Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4. Application of Seamless Pipe ASTM A106/53

Seamless stainless pipe is used for applications that require internal pressure within the pipe such as process equipment, water treatment and marine applications. Welded pipe is used for structural applications that are exposed to corrosive environments such as marine and external applications. These include handrails, poles and support piping.

5.Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 50-60days after received 30%TT or Original LC |

6.FAQ of Seamless Pipe ASTM A106/53:

How is the quality of your products?

A. Our products are manufactured strictly according to national and internaional standard, and we take a test on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

B.How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

C. Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

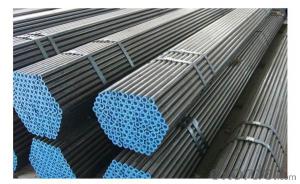

7. Seamless Pipe ASTM A106/53 Images:

8. Company Information:

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

Since 2004, the trading volume of CNBM International has been doubled in 5 successive years owing to the support of superior corporations and effort of all staff. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target.

In line with the business, CNBM International launched E-business platform Okorder.com.Our goal is to transform CNBM International into the global leading brand in building materials industry within 3 to 5 years through innovation and reform, by strengthening the overall management of supply chain, developing and cultivating both domestic and overseas market, improving the procedure and information system, enhancing the ability to organize resources and to provide value-added services under a professional team and a learning organization.

- Q: How are steel pipes used in the manufacturing sector?

- Steel pipes are widely used in the manufacturing sector for various purposes such as transporting fluids, gases, and solid materials, as well as providing structural support in buildings and machinery. They are commonly used in industries like oil and gas, construction, automotive, and manufacturing plants for their durability, strength, and resistance to corrosion. Steel pipes enable efficient and reliable transportation of materials, facilitating the manufacturing process and ensuring the smooth operation of industrial systems.

- Q: What is hot rolled steel pipe? What is a cold drawn steel tube?

- Overview of two processesHot-rolled (extrusion seamless pipe): billet, heating, perforation, three roll cross rolling, rolling or extrusion, tube to tube diameter (or reducing) - cooling - tube, straightening, pressure test (or testing), marking and warehousing.Cold drawing (rolling) seamless steel pipe: round tube to heating to perforation, annealing, pickling, leading to oil (copper), multi pass drawing (Leng Zha), the blank pipe, heat treatment, straightening, pressure test (testing), marking and warehousing.

- Q: How do you calculate the pipe volume flow rate for steel pipes?

- To calculate the volume flow rate of steel pipes, you need to consider the pipe's diameter and fluid velocity. The formula used for this calculation is Q = A * V, where Q represents the volume flow rate, A is the cross-sectional area of the pipe, and V is the fluid velocity. To start, you need to determine the cross-sectional area of the pipe. For a circular pipe, you can use the formula A = π * r², where A is the area and r is the radius of the pipe. If the diameter of the pipe is given, you can simply divide it by 2 to obtain the radius. Next, you need to determine the fluid velocity. This can be done by measuring the velocity directly using a flowmeter or by calculating it based on the fluid's properties and the pressure drop across the pipe using the Bernoulli equation or other appropriate equations. Once you have both the cross-sectional area and fluid velocity, you can multiply them together to find the volume flow rate. Make sure the units are consistent throughout the calculation. For example, if the area is in square meters and the velocity is in meters per second, the resulting volume flow rate will be in cubic meters per second. It is worth noting that the calculation assumes the fluid is incompressible and flows steadily through the pipe. If the fluid properties or flow conditions change, additional considerations may be required to accurately calculate the volume flow rate.

- Q: What are the advantages of using steel pipes in construction projects?

- There are several advantages of using steel pipes in construction projects. Firstly, steel pipes are incredibly strong and durable, making them ideal for carrying heavy loads and withstanding harsh environmental conditions. Secondly, steel pipes have a high resistance to corrosion, which ensures a longer lifespan and reduces maintenance costs. Additionally, steel pipes are lightweight, making them easier to transport and install. Lastly, steel pipes are versatile and can be used for various applications such as water supply, sewage systems, gas pipelines, and structural support.

- Q: How are steel pipes used in irrigation systems?

- Steel pipes are commonly used in irrigation systems to transport water from a water source, such as a well or reservoir, to the fields or crops that need to be irrigated. These pipes are durable, strong, and resistant to weathering and corrosion, making them ideal for outdoor use. They can be laid underground or above ground, and their flexibility allows for easy installation and maintenance. Steel pipes in irrigation systems ensure a reliable and efficient water supply to promote healthy plant growth and maximize crop yields.

- Q: What are the different types of steel pipe supports for thermal expansion?

- There are several different types of steel pipe supports that can be used for thermal expansion, including rigid supports, sliding supports, and spring supports. Rigid supports provide fixed support to the pipe and do not allow for any movement. Sliding supports allow the pipe to move horizontally as it expands or contracts, while still providing vertical support. Spring supports use springs to support the weight of the pipe and allow for vertical movement as well as thermal expansion.

- Q: How are steel pipes measured?

- Steel pipes are typically measured by their outer diameter (OD) and wall thickness. The OD is measured using a caliper or tape measure, while the wall thickness is determined using specialized tools like ultrasonic gauges or micrometers. These measurements are crucial for determining the pipe's size, strength, and suitability for various applications.

- Q: Can steel pipes be coated for aesthetic purposes?

- Indeed, steel pipes have the potential to be coated solely for aesthetic reasons. By applying coatings to steel pipes, not only can one achieve an attractive appearance, but also safeguard them against corrosion and other environmental influences. Numerous coating choices are at one's disposal when it comes to steel pipes, including powder coating, epoxy coating, and vinyl coating, among others. These coatings can be employed in various colors and textures to enrich the pipes' visual appeal and harmonize with their surroundings. Whether utilized in industrial settings, architectural endeavors, or for decorative purposes, the act of coating steel pipes has the power to metamorphose them into visually captivating components, all while preserving their structural integrity.

- Q: How do you join steel pipes together?

- Steel pipes can be joined together using various methods, including welding, threading, and using mechanical couplings.

- Q: What are the typical lengths of steel pipes?

- The typical lengths of steel pipes can vary depending on their purpose and application. However, common lengths range from 20 feet (6 meters) to 40 feet (12 meters) in commercial and industrial settings.

Send your message to us

ASTM A53/A106/ API 5L GrB Sch40 Seamless Galvanized Carbon Steel Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords