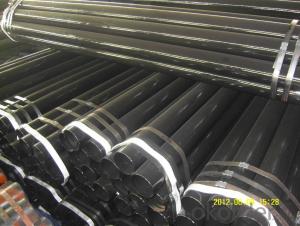

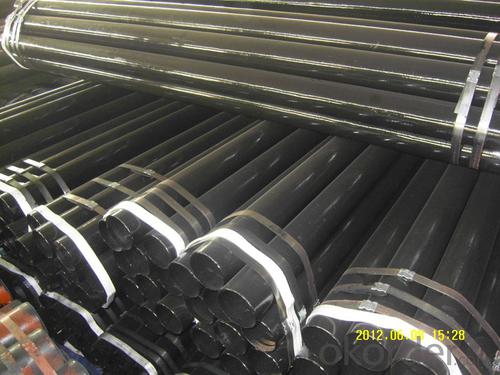

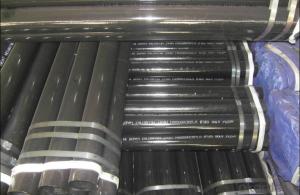

ASTM A 106 GRB cold drawn seamless steel pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Thickness: | 1 - 80 mm | Section Shape: | Round | Outer Diameter: | 6 - 2020 mm |

Place of Origin: | Shandong China (Mainland) | Secondary Or Not: | Non-secondary | Application: | Oil Pipe |

Technique: | Cold Drawn,Seamless | Certification: | API | Surface Treatment: | Copper Coated |

Special Pipe: | API Pipe | Alloy Or Not: | Is Alloy | Grade: | 20#,45#,15CrMo,10CrMo910,13CrMo44,12Cr2Mo,12CrMo195,12Cr1MoVG,API J55,API K55,St37,St52,St35.8,St37-2,St42-2,10#-45#,Cr-Mo alloy,API J55-API P110,ST35-ST52 |

Standard: | GB 5310-1995,GB 3087-1999,GB/T 8163-1999,GB/T 8162-1999,GB/T 9711.1-1997,GB 13296-2007,GB/T 3091-2001,GB/T 3089-1982,GB/T 17396-1998,GB/T 12771-2000,GB |

Packaging & Delivery

Packaging Detail: | Export packing or as your demand. |

Delivery Detail: | depend on the QTY you need. |

Specifications

cold drawn seamless steel pipes

1)Grade:20#,45#,16Mn C20,C45,St52 A106 A53

2)OD10.3mm--1219mm WT SCH5S--XXS

3)High quality

Standard | Steel Grade | Standard Name | Dimension |

No | Range | ||

EN 10208 | L210GA,L235GA,L245GA,L290GA, | Steel Pipes for Pipelines for | 33.7-1626mm |

L360GA,L245NB, L290NB,L360NB, | Combustible Fluids | ||

L415NB, L360QB, LI15QB,L450QB, | |||

L485QB,L555QB | |||

EN 10210 | S235JRH,S275JOH,S275J2H,S355JOH, | Hot Finished Structural | 21.3-1219mm |

S355J2H,S355K2H,S275NH,S275NLH, | Hollow Sections of Non-alloy | ||

S355NH,S355NLH,S420NH,S420NLH, | and Fine Grain Steels | ||

S46INH,S460NLH | |||

EN 10216-1 | P195TRI,P195TR2,P235TR1, | Seamless Steel Tubes for | 10.2-711mm |

P235TR2, P265TR I, P265TR2 | Pressure Purposes-1- | ||

Non-alloy Steel Tubes with | |||

Specified Room Temperature | |||

Properties | |||

EN 10216-2 | P195GH, P235GH, P265GH, | Seamless Steel Tubes for | 10.2-711mm |

20MnNb6,16Mo3, 8MoB5-4, | Pressure Purposes-2: | ||

14MoV6.3, 10CrMo5.5,13CrMo4-5, | Non-alloy and Alloy Steel | ||

10CrMo9-10, 11CrMo9.10, | Tubes with Specified Elevated | ||

25CrMo4,20CrMoV13-5-5, | Temperature Properties | ||

15 NiCuMoNB-6-4,X11CrMo5+1, | |||

X11CrMo5+NTI,X11CrMo5+NT2, | |||

X11CrMo9.1+1, X11CrMo9.1+NT, | |||

X10CrMoVNb9-l, X20CrNiV11-1 | |||

EN 10216-3 | P275NL I,P275NL2, P355N,P355NH, | Seamless Steel Tubes for | 10.2-711mm |

P355NL1,P355NL2,P460N,P460NH, | Pressure Purposes-3: | ||

P460NL1,P460NL2,P620Q,P620QH,P620QL, | Alloy Fine Grant Steel Tubes | ||

P690Q,P690QH,P690OL1,P690QL2 | |||

EN10216-4 | P215NL,P255QL,P265NL, | Seamless Steel Tubes far | 10.2-711mm |

26CrMo4.2,11MnNi5-3,13MnNi6-3, | Pressure Purposes-4: | ||

12Nil4,Xl2Ni5,X10Ni9 | Non-alloy aid Alloy Steel | ||

Tubes with Specified Low | |||

Temperature Properties | |||

EN 10224 | L235, L275, L355 | Non-alloy Steel Tubes and | 26.9-2743mm |

Fittings for the Conveyance of | |||

Water and Other Aqueous | |||

Liquids | |||

EN 10297-1 | E235,E275,E315,E355,E470, | Seamless Circular Steel Tubes | 26.9-610mm |

E275K2,E355K2,E420J2,E460K2, | for Mechanical mid General | ||

E590K2,F730K2 C22E,C35E,C45E,C60E, | Engineering Purposes-1: | ||

38Mn6,41Cr4,25CrMo4,30CrMo4, | Non-alloy and Alloy | ||

34CrMo4,42CrMo4,36CrNiMo4, | Steel Tubes | ||

30CrNiMo8,4lNiCrMo7-3-2 | |||

EN 10305-1 | E215,E235,E355 | Steel Tubes For Precision | 4-260mm |

Applications-1: | |||

Seamless Cold Drawn Tubes | |||

EN 10305-4 | E215,E235,E355 | Steel Tubes for precision | 4-80mm |

Applications-4: | |||

Seamless Cold Drawn Tubes | |||

for Hydraulic mid Pneumatic | |||

Power Systems |

- Q: Can steel pipes be used for underground stormwater drainage?

- Indeed, underground stormwater drainage can utilize steel pipes. These pipes possess durability and boast a high strength-to-weight ratio, rendering them appropriate for subterranean usage. They can endure substantial burdens and fend off corrosion, thus guaranteeing sustained effectiveness within stormwater drainage systems. Furthermore, steel pipes lend themselves to easy welding, facilitating customization and flexibility during both design and installation. Nonetheless, it is imperative to implement adequate corrosion protection measures, such as the application of a protective coating or the utilization of corrosion-resistant alloys, to avert degradation over time. Regular maintenance and monitoring are also advisable to uphold the pipes' integrity and ensure optimal stormwater drainage functionality.

- Q: What are the different methods of repairing steel pipes?

- There are several methods for repairing steel pipes, including welding, pipe wrapping, pipe lining, and pipe bursting. Welding involves fusing the damaged sections of the pipe using heat and pressure. Pipe wrapping involves using a fiberglass or epoxy resin wrap to reinforce and seal the damaged areas. Pipe lining involves inserting a new pipe into the damaged one, creating a seamless and corrosion-resistant inner lining. Pipe bursting involves replacing the damaged pipe by using a bursting head to break it apart while simultaneously pulling a new pipe into place. The choice of method depends on the nature and extent of the damage, as well as other factors such as cost and accessibility.

- Q: What is the maximum diameter of steel pipes?

- The maximum diameter of steel pipes can vary depending on various factors such as manufacturing capabilities, industry standards, and specific project requirements. However, steel pipes can typically range from a few millimeters in diameter for small-scale applications to several meters in diameter for large-scale industrial projects.

- Q: How are steel pipes protected against mechanical damage during transportation?

- Various measures are implemented to safeguard steel pipes against mechanical damage during transportation. One commonly used technique involves the application of protective coatings or wrapping materials, typically composed of plastic, rubber, or epoxy. These coatings serve as a physical barrier, shielding the pipes from scratches, dents, and other forms of mechanical harm. Another method involves the utilization of padding or cushioning materials, such as foam inserts or rubber gaskets. These materials are inserted inside or wrapped around the pipes, absorbing any impacts or shocks that may occur during transportation. This effectively prevents potential damage caused by vibrations or bumps. Additionally, steel pipes are frequently secured and immobilized within transportation containers through the use of straps, braces, or other securing devices. These measures ensure that the pipes remain stable and do not collide with one another, thereby minimizing the risk of mechanical harm. Furthermore, proper handling and loading techniques play a crucial role in protecting steel pipes during transportation. This involves the utilization of appropriate lifting equipment, such as cranes or forklifts, to prevent any accidental dropping or mishandling of the pipes. Moreover, pipes are often stored or stacked in a manner that minimizes the possibility of deformation or bending. Ultimately, a combination of protective coatings, cushioning materials, securement devices, and proper handling techniques are employed to ensure the safe transportation of steel pipes and maintain their optimal condition for use in various applications.

- Q: Can steel pipes be used for conveying steam?

- Yes, steel pipes can be used for conveying steam. Steel pipes are commonly used in steam systems due to their high strength and durability, as well as their ability to withstand high temperature and pressure conditions. However, it is important to ensure that the steel pipes are properly insulated and the system is adequately designed to prevent any potential issues such as corrosion or thermal expansion.

- Q: How do you calculate the pipe head loss for steel pipes?

- To calculate the pipe head loss for steel pipes, you can use the Darcy-Weisbach equation. This equation relates the head loss (hL) to the flow rate (Q), pipe diameter (D), pipe length (L), fluid density (ρ), fluid velocity (V), and a friction factor (f). The formula is as follows: hL = (f * (L/D) * (V^2))/(2g) Where: - hL is the head loss (measured in meters) - f is the friction factor (dimensionless) - L is the pipe length (measured in meters) - D is the pipe diameter (measured in meters) - V is the fluid velocity (measured in meters per second) - g is the acceleration due to gravity (usually taken as 9.81 m/s^2) The friction factor (f) depends on the Reynolds number (Re) of the flow, which is a dimensionless quantity representing the ratio of inertial forces to viscous forces. The Reynolds number can be calculated as: Re = (ρ * V * D) / μ Where: - Re is the Reynolds number (dimensionless) - ρ is the fluid density (measured in kg/m^3) - V is the fluid velocity (measured in meters per second) - D is the pipe diameter (measured in meters) - μ is the dynamic viscosity of the fluid (measured in Pa·s or N·s/m^2) The friction factor (f) can be obtained from empirical correlations or from Moody's diagram, which relates it to the Reynolds number and the relative roughness of the pipe surface. By substituting the calculated friction factor (f) and other known values into the Darcy-Weisbach equation, you can determine the head loss in the steel pipe. It is important to note that the head loss is a measure of energy loss due to friction and other factors, and it is typically expressed in terms of pressure drop or height difference.

- Q: How are steel pipes protected during transportation and storage?

- Steel pipes are usually protected during transportation and storage through various measures such as coating them with anti-corrosion materials, wrapping them with protective films or tapes, using wooden crates or pallets for stacking and securing them with straps or bands. Additionally, pipes are often stored in covered or climate-controlled warehouses to prevent exposure to moisture and other potential damaging elements.

- Q: Can steel pipes be used for natural gas processing plants?

- Yes, steel pipes can be used for natural gas processing plants. Steel pipes have excellent strength and durability, making them suitable for transporting and processing natural gas. They can withstand high-pressure conditions and are resistant to corrosion, providing a safe and reliable option for gas processing facilities.

- Q: How do you calculate the pipe buoyancy for steel pipes in water?

- The buoyancy of steel pipes in water can be calculated by determining the weight of the water displaced by the submerged portion of the pipe. This can be done by multiplying the volume of the submerged portion of the pipe by the density of water. The buoyant force acting on the pipe can then be calculated by multiplying the weight of the displaced water by the acceleration due to gravity.

- Q: Are steel pipes suitable for underground sewage systems?

- Yes, steel pipes are suitable for underground sewage systems. Steel pipes are known for their strength, durability, and resistance to corrosion, making them an ideal choice for underground installations. Steel pipes can withstand the pressure and weight of the soil above, ensuring the integrity of the sewage system. Additionally, steel pipes have a long lifespan and can withstand extreme temperatures and environmental conditions, making them a reliable choice for underground applications. However, it is important to note that proper coating and insulation should be applied to steel pipes to prevent corrosion and ensure longevity.

Send your message to us

ASTM A 106 GRB cold drawn seamless steel pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords