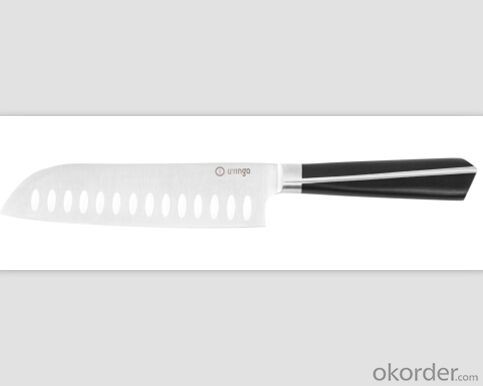

Art no. HT-KP1007 Stainless steel knife set

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Set includes:

1 × utility knife

1 × carving knife

1 × chopping knife

High-carbon stainless steel blade holds a superior sharp edge

High quality stainless steel,tool vertical tough strong corrosion resistance

Comfortable grip handle for balance and control

Many other designs are available

Customized orders are accepted

Features:

No slot foldable magnetic wooden knife block

Seamless welding technique

Fashionable and comfortable handle design

Multifunction kitchen knife set meets customer's needs during cooking

Stainless steel knife blade with logo printed

Hard enough and sharp for cutting food

Easy to clean and save space

Fashion designnable design

Customized designs are welcome

OEM orders are welcome

Product advantages:

Wear resistant & extremely durable

Deathly sharp & stay sharp for years

Easy to clean to prevent bacteria growth

Blade high in density, chemically inert will not rust and do not react with acidic, food keep its original taste. No metal taste and smell

- Q: How to select the tool according to the material

- This thing can not say anything about the knife? Welding knife T15 steel YW1 stainless steelIt is a brand of CNC blade number one brand that is not clear as Japan's MITSUBISHI UE6010 UC5115 US735 stainless steel cast iron ceramic blade is generally more common number is P M K standard (stainless steel cast iron and aluminum)

- Q: What are the commonly used tool materials

- High speed steel, cemented carbide, diamond, CBN., ceramic

- Q: How long is the control tool?

- The knife body is more than eight cm, and the utility model is provided with a self-locking device or a non folding single edge and double edge knife

- Q: In machining, the relationship between the speed and the feed rate is very important

- In machining, according to the general tool material and machining parts to determine the angle and the cutting speed of Vf, is generally more common in the 60 to 200 range, please note that this range is to experience the value based on the cutter shape, material and machining materials, and then according to the formula to calculate the 1000Vf=3.14*d*n speed. Feed is mainly related to the rigidity of the processing equipment and the processing of the material of the material, generally coarse feed in the 0.3mm/ turn, fine processing feed 0.05 ~ 0.15mm of the majority.

- Q: What are the factors that affect the tool life

- Cutting fluid quality.In addition to cutting fluid in the process of metal processing to improve lubrication, as well as the role of cleaning and rust prevention. The cleaning and chip removal of cutting fluid is often indispensable in metal cutting.

- Q: CNC machine tools and cutting tools for the performance of the material requirements?

- No special needs. Due to the general use of CNC machine tools for high efficiency and accuracy requirements, so try to use some of the more high-end tools.For example, selection of hard alloy steel processing (coated better), if the machining of hardened steel can also use the CBN (cubic boron nitride) blade, if you are aluminum processing can use PCD (directional crystal diamond tool).In order to reduce the uncertainty in the production, the use of non grinding machine tool. This can reduce human factors, so that the production system is more stable. Of course, you have to have enough high value-added products.

- Q: What is the most important influence on the cutting tool?

- The feed is small, the flank wear is large, the tool life is greatly reduced. Feed, cutting temperature increases, the flank wear will increase, but the cutting speed than the impact on the tool life is small, of course, a large amount of feed, processing efficiency is also high.

- Q: What is the relative motion between the tool and the blank?

- The linear speed of the gear cutter and the gear blank.

- Q: Why can't we use diamond tools to process iron materials?

- If you have to use diamond tools to process the iron material, you need to do a good job cooling, increasing the chip space, reducing the cutting force and other points, it is possible to process iron materials

- Q: What are the features of the CBN tool?

- The low CBN material grades are more brittle than the CBN ones, but they are better used for hardening ferrous metals. They have lower thermal conductivity and relatively higher compressive strength under high speed cutting and negative rake angles. The cutting zone has a higher temperature to soften the workpiece material and help to break the chip, while the negative rake angle strengthens the cutting tool, so that the cutting edge is stable, the tool life is improved, and the cutting depth is smaller than 0.25mm.

Send your message to us

Art no. HT-KP1007 Stainless steel knife set

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords