API 5L GR.B X52 ERW PIPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Welded Steel Tube:

Welded Steel Tube is produced by drawing a solid billet over a piercing rod to create the hollow shell. We will provide you high quality of welded pipe and professioanl service.

2、Main Features of the Welded Steel Tube:

• High manufacturing accuracy

• The higher strength

• The small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Satisfy price

3、Welded Steel Tube Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Welded Steel Tube:

①How is the quality of your products?

Our products are strictly in accordance with international and domestic standard. We test on every pipe before delivery. Any quality certification or testing report you want to see, please tell us.

Guaranteed: If products’ quality is not in accordance with description as we provide or the promise before you place order, we promise 100% refund.

②How about the price?

We want to save your time and be absolutely honest with our business relationship, so we quote as low as possible for every client. Besides, discount can be given according to the quantity. if you dissatisfy with our factory price, just don’t waste your time. Our quotation is professional and reasonable.

③Why should you choose us?

Choice happens because of our quality and price. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), fast goods delivery, outstanding customer solution proposals. Our service formula: good quality + good price + good service=customer’s trust.

SGS test is available. Customer inspection before shipping is welcome. Third party inspection is OK.

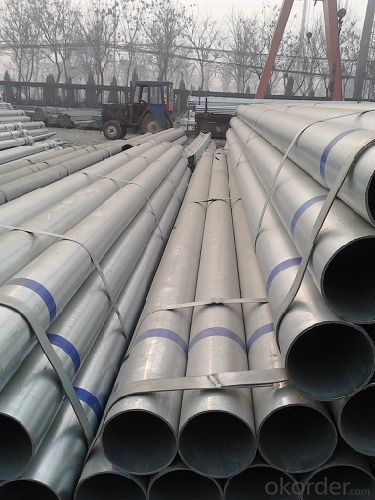

6、 Welded Steel Tube Images:

- Q: How are steel pipes used in mining?

- Steel pipes are widely used in mining operations for various purposes. One of the primary uses of steel pipes in mining is for transporting materials such as water, slurry, and other liquids. These pipes are durable and can withstand the harsh conditions often found in mining environments, making them suitable for the transportation of materials over long distances. Steel pipes are also used for ventilation systems in mines. Proper ventilation is crucial in mining to provide fresh air to workers and remove harmful gases and dust. Steel pipes are used to construct ventilation shafts and ducts that facilitate the flow of air throughout the mine, ensuring a safe working environment for the miners. Additionally, steel pipes are used in the construction of underground tunnels and mine shafts. These pipes provide structural support and reinforcement, helping to prevent collapses and maintain the stability of the mine. Steel pipes are known for their strength and durability, making them an ideal choice for these critical applications in mining. Another application of steel pipes in mining is for the extraction of resources. In some cases, steel pipes are used to create boreholes or wells to access underground deposits of minerals or water. These pipes are inserted into the ground, and various techniques such as drilling or hydraulic fracturing are used to extract the desired resources. Overall, steel pipes play a vital role in the mining industry, serving various purposes such as material transportation, ventilation, structural support, and resource extraction. Their strength, durability, and ability to withstand harsh conditions make them indispensable in mining operations.

- Q: How are steel pipes threaded for easy installation?

- Steel pipes are threaded for easy installation using a process called threading. Threading involves cutting grooves or ridges into the pipe to create a spiral pattern. This pattern allows the pipe to easily connect with other threaded components, such as fittings or valves. There are two common methods used to thread steel pipes: manual threading and machine threading. In manual threading, a handheld tool called a pipe die is used. The die is equipped with sharp teeth that cut into the pipe as it is rotated. The pipe is secured in a vise or held firmly by hand, and the die is applied to the end of the pipe. The die is then rotated around the pipe, creating the threaded grooves. This process requires skill and precision to ensure accurate and properly aligned threads. Machine threading, on the other hand, is a more automated process. It involves the use of a pipe threading machine, which is equipped with a die head that automatically cuts the threads into the pipe. The machine secures the pipe and rotates it while the die head moves along the length of the pipe, cutting the threads. Machine threading is faster and more efficient than manual threading, making it ideal for large-scale production or projects. Regardless of the method used, it is crucial to ensure that the threads are clean and free from debris or burrs. This is important for easy installation and to prevent leaks or other complications. After threading, the pipes are typically inspected to ensure the threads meet the required specifications. Threading steel pipes allows for easy installation as the threaded ends can be easily screwed into fittings, valves, or other pipes with compatible threads. This threaded connection creates a tight seal, making it suitable for various applications, such as plumbing, gas lines, or industrial piping systems.

- Q: How do you determine the required support spacing for steel pipes?

- Various factors, including the diameter of the pipe, the strength of the material, the operating conditions, and local building codes and regulations, determine the required support spacing for steel pipes. When considering the diameter of the pipe, it is crucial to note that larger pipes generally need more frequent support to prevent excessive deflection and sagging compared to smaller pipes. The strength of the material is also a significant consideration, as pipes with greater strength can span longer distances without requiring additional support. The operating conditions of the pipe, such as the type of fluid being transported and the temperature, also play a role in determining the necessary support spacing. For instance, pipes carrying heavy or corrosive fluids may require more frequent support to prevent excessive stress and potential failure. Local building codes and regulations often provide specific guidelines for the minimum support spacing of steel pipes. These regulations take into account factors such as the diameter of the pipe, the strength of the material, the operating conditions, as well as safety and structural requirements. To accurately determine the required support spacing for steel pipes, it is essential to consult relevant codes, standards, and engineering guidelines. Additionally, working with qualified engineers and professionals experienced in pipe design and installation will ensure that the support spacing meets all necessary requirements, ensuring the safe and efficient operation of the piping system.

- Q: How are steel pipes insulated to prevent noise transmission?

- Steel pipes are typically insulated to prevent noise transmission by using materials such as fiberglass or mineral wool wraps. These insulating materials are wrapped around the pipes, creating a barrier that absorbs and dampens sound waves, reducing noise transmission. Additionally, acoustic lagging or jackets can also be applied to further reduce noise and vibration.

- Q: Can steel pipes be used for hydropower systems?

- Yes, steel pipes can be used for hydropower systems. Steel pipes are commonly used in hydropower systems for various applications such as penstocks, which are used to transport water from a reservoir to a turbine. Steel pipes are preferred for their strength, durability, and ability to withstand high pressure and water flow. They are also resistant to corrosion, making them suitable for long-term use in hydropower systems. Additionally, steel pipes can be easily welded or joined, allowing for flexibility in system design and installation. Overall, steel pipes are a reliable and widely used choice for hydropower systems.

- Q: How do you determine the wall thickness of a steel pipe?

- The wall thickness of a steel pipe can be determined by measuring the outer diameter (OD) and the inner diameter (ID) of the pipe, and then subtracting the ID from the OD.

- Q: What connections are there for concrete filled steel tubular column foundations?

- Application of double beam connection node usually uses "I" shape columns and steel bracket which is around the construction technology of a modern steel concrete column girder casting formed in the steel pipe outside through the two structures, the bearing pin four axis and four angles on the common components of stress transfer. The construction technology in the application is usually used at both ends of the stress transfer construction mode, through the four steel bracket to the corresponding shear stress, avoid crack width because the node contact produces clear, delayed cracks, improve anti cracking ability of regional nodes.This node model in the connection when the longitudinal reinforcement without through the tube, without bending the construction can be carried out directly, with easy construction technology, construction control difficulty, the economic benefits of construction at the same time, the advantage of low reinforcement to save. In this joint engineering technology, the key pride is to control the stress transfer of steel bracket.

- Q: What is the creep resistance of steel pipes?

- The ability of steel pipes to withstand deformation or elongation over time when exposed to high temperatures and constant stress is referred to as their creep resistance. Steel pipes are highly regarded for their exceptional resistance to creep because of the inherent strength and stability of the material. The creep resistance of steel pipes can vary depending on factors like the composition of the alloy, heat treatment, and the conditions in which they are used. Creep is a phenomenon that occurs at elevated temperatures, causing materials to slowly deform under constant stress. In the case of steel pipes, this can be a concern in applications where they are subjected to high temperatures for extended periods, such as in power plants, industrial furnaces, or steam pipelines. The ability to resist creep deformation is crucial to maintain the structural integrity and longevity of the pipes. Steel pipes are often designed and manufactured using alloys with high creep resistance properties, such as chromium-molybdenum (Cr-Mo) steels or nickel-based alloys. These alloys possess excellent mechanical strength, thermal stability, and resistance to oxidation and corrosion, all of which contribute to their superior creep resistance. Moreover, heat treatment processes like quenching and tempering can significantly enhance the creep resistance of steel pipes. These treatments involve controlled heating and cooling cycles to optimize the microstructure of the steel, thereby increasing its resistance to deformation and improving its overall performance at high temperatures. It is important to note that the creep resistance of steel pipes is typically specified by industry standards and codes, such as the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code. These standards define the allowable stress levels and design criteria for different steel pipe applications, ensuring that they meet the necessary safety and performance standards. In summary, steel pipes are renowned for their excellent creep resistance due to their inherent strength, stability, and ability to withstand high temperatures. The specific creep resistance of steel pipes may vary depending on factors such as alloy composition, heat treatment, and operating conditions. Proper design and adherence to industry standards are essential to ensure the desired creep resistance and overall performance of steel pipes in various applications.

- Q: Can steel pipes be used for scaffolding and support structures?

- Indeed, scaffolding and support structures can make use of steel pipes. Due to their robustness, longevity, and ability to bear substantial loads, steel pipes are commonly employed in the construction industry. They establish a steady and secure framework for scaffolding and support structures, guaranteeing the safety of workers and the stability of the construction undertaking. Moreover, steel pipes possess versatility, enabling convenient assembly and disassembly, rendering them a superb option for temporary structures such as scaffolding. Furthermore, steel pipes exhibit resistance to corrosion, rendering them appropriate for outdoor applications and ensuring the enduring existence of the scaffolding and support structures.

- Q: Are steel pipes suitable for food processing facilities?

- Steel pipes are indeed appropriate for food processing facilities. They are extensively used in the food processing industry because of the multitude of advantages they offer. To begin with, steel pipes are highly durable and can withstand the high temperatures, pressures, and corrosive substances commonly used in food processing. This means that the pipes will not degrade or contaminate the food products. Moreover, steel pipes are easy to clean and maintain, which makes them perfect for upholding the high levels of hygiene required in food processing facilities. Furthermore, steel pipes possess excellent resistance to bacteria growth, thereby ensuring the safety and quality of the food being processed. Additionally, steel pipes are cost-effective and have a long lifespan, making them a dependable and economical choice for food processing facilities. In conclusion, steel pipes are a suitable and preferred option for food processing facilities due to their durability, cleanliness, and resistance to contamination.

Send your message to us

API 5L GR.B X52 ERW PIPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords