API-5CT EUE Tubing Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000ton m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

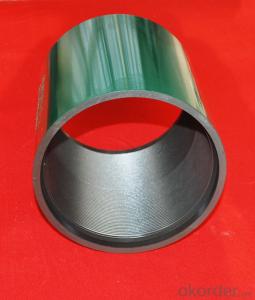

API-5CT EUE Tubing Pipe

The API external-upset-end (EUE) tubing pipe is broadly used due to the fact that is a good, serviceable interconnection in the majority of wells.

Without the need of modifying the actual thread shape, the joint dimension will increase because of upsetting procedure. The EUE joint features a designed joint strength in tension and pressure strength much higher than that of the pipe overall body and, as a result, is considered a 100% joint effective connection.

To enhance seal efficiency of API EUE tubing in high-pressure system, a grooved coupling, which accepts nonmetallic seal rings, is quite often applied in the coupling (see API Spec. 5CT SR 13).

API EUE joints come in OD sizes of 1.050 to 4.500 inch.

| Parameters | Value | |

|---|---|---|

| Material | J55, K55, N80, N80Q, L80, P110, other grade available as your requirement | |

| Outer Diameter | 2-3/8"~4-1/2" (73.02~114.3mm) | |

| Wall Thickness | 4.83~16mm | |

| Forms of Thread | EUE, NUE and Integral-joint | |

| Length Range | R1(20~24ft), R2(28~32ft) | |

| MTR | accordance with API Specification 5CT |

Tolerances

| Parameters | Value | |

|---|---|---|

| Outside diameter | +-0.031 inch (0.79mm) | |

| Wall thickness | -12.5%, positive deviations are limited by pipe weight | |

| Weight Deviation | +6.5% /-3.5% |

Mechanical Properties

| Grade | Tensile Strength (PSI/MPa) | Yield Strenght (PSI/MPa) | ||

|---|---|---|---|---|

| H-40 | No less than 60000(414) | Between 40000 (276) ~ 80000 (552) | ||

| J-55 | No less than 75000 (517) | Between 55000 (379) ~ 80000 (552) | ||

| N-80 | No less than 100000 (689) | Between 80000 (552) ~ 110000 (758) | ||

| P-110 | No less than 125000 (862) | Between 110000 (758) ~ 140000 (965) |

Inspection

Physical properties are checked and each length hydrostatically tested, normally to only 3,000 psi in the plain end (unthreaded) condition. The following are also checked:

Dimensions

Weights

Straightness

Lengths

Part of this inspection is to drift all lengths.

Despite all the American Petroleum Institute (API) specifications and testing, some tubing defects are still found after delivery; thus, some operators do further inspection.

Inspection Method

Size and surface inspection

NDT and pressure test and third party certication

Hydrostatic

Drifting test

Physical and chemicail analysis

Hardness and pressure test.

Electromagnetic

Magnetic particle

Ultrasonic

Dimensions and Weight

sizes | ODD | weight | wtt | Type of end | |||||||||||

1 | 2 | NU kg/m | EU kg/m | IJ kg/m | |||||||||||

NU | EU | IJ | |||||||||||||

H40 | J55 | L80 | N80 1¸Qàà | C90 | T95 | P110 | |||||||||

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

2-3/82-3/82-3/8 | 4.004.605.80 | -4.705.95 | — | 60.3260.3260.32 | 5.956.858.63 | -6.998.85 | — | 4.244.836.45 | PUPNU- | PNPNU- | PNPNUPNU | PNPNUPNU | PNPNUPNU | PNPNUPNU | -PNUPNU |

2-7/82-7/82-7/8 | 6.407.808.60 | 6.507.908.70 | — | 73.0273.0273.02 | 9.5211.6112.80 | 9.6711.7612.95 | — | 5.517.017.82 | PNU– | PNU– | PNUPNUPNU | PNUPNUPNU | PNUPNUPNU | PNUPNUPNU | PNUPNUPNU |

3-1/23-1/23-1/2 | 7.709.2010.20 | -9.30- | — | 88.9088.9088.90 | 11.4613.6915.18 | -13.84- | — | 5.496.457.34 | PNPNUPN | PNPNUPN | PNPNUPN | PNPNUPN | PNPNUPN | PNPNUPN | -PNU- |

444 | 9.5010.7013.20 | -11.00- | — | 101.60101.60101.60 | 14.14-19.64 | -16.37- | — | 5.746.658.38 | PNPU- | PNPU- | PNPUP | PNPU- | PNPUP | PNPUP | — |

4-1/24-1/2 | 12.6015.20 | 12.75- | – | 114.30114.30 | 18.7522.62 | 18.97- | – | 6.888.56 | PNU- | PNU- | PNUP | PNU- | PNUP | PNUP | – |

4-1/24-1/24-1/2 | 17.0018.9021.50 | — | — | 114.30114.30114.30 | 25.3028.1332.00 | — | — | 9.6510.9212.70 | — | — | PPP | — | PPP | PPP | — |

P——Plain end;N—Non-upset threaded and coupled;U—External upset threaded and coupled;I—insert joint. | |||||||||||||||

Dalipal Company is one of the most famous enterprises of china professionally producing pipeline and oil casing.We can supply API 5CT series of pipeline and oil casing with all kinds of specifications and materials.We have first-class production equipment and technology.

- Q: What type of steel pipe dance is used in general?

- According to international competition practice, the standard size of steel tube is 40 mm or 45 mm in diameter, and the 45mm is usually used. The height of the steel pipe is not less than 3.3 meters and not higher than 4 meters.

- Q: What is the difference between steel pipes and PPR pipes?

- Steel pipes are made of steel and are primarily used for transporting liquids and gases in industries such as oil, gas, and construction. They are durable, resistant to high temperatures and pressure, and have a long lifespan. On the other hand, PPR (polypropylene random copolymer) pipes are made of plastic and are commonly used for plumbing systems in residential and commercial buildings. PPR pipes are lightweight, easy to install, corrosion-resistant, and have good thermal insulation properties. They are more suitable for carrying water and other non-corrosive fluids.

- Q: How many fasteners are there in a ton of steel tubes?

- The fastener generally refers to the intermediate connecting parts connecting two members, in the construction project for external diameter of steel pipe scaffold with 48mm fixation, the fastener is divided into rectangular fastener (cross directional fastener fastener) rotary fastener (universal movable fastener fastener) (a direct docking fastener fastener fastener) etc..

- Q: What are the common applications of galvanized steel pipes?

- Galvanized steel pipes are commonly used in various industries and applications such as plumbing, water supply systems, gas pipelines, electrical conduits, construction projects, fencing, and outdoor structures. The galvanization process adds a protective zinc coating to the steel, making it resistant to corrosion and extending its lifespan, making it ideal for applications requiring durability and longevity.

- Q: Can steel pipes be used for underwater applications?

- Yes, steel pipes can be used for underwater applications as they are known for their high strength, durability, and corrosion resistance, making them suitable for various underwater environments and industries such as offshore oil and gas, marine construction, and underwater pipelines.

- Q: What are the different manufacturing standards for steel pipes?

- There are several manufacturing standards for steel pipes that are widely recognized and implemented in the industry. These standards ensure that the steel pipes are produced to meet specific requirements and quality standards. Some of the most common manufacturing standards for steel pipes include: 1. American Society for Testing and Materials (ASTM): ASTM standards are widely used in the United States and cover a wide range of steel pipe specifications. These standards include specifications for seamless and welded steel pipes, as well as various grades and dimensions. 2. International Organization for Standardization (ISO): ISO standards are globally recognized and provide guidelines for the production of steel pipes. ISO standards cover areas such as dimensions, materials, testing, and quality control. 3. European Norm (EN): EN standards are applicable in Europe and provide specifications for various types of steel pipes. These standards cover aspects such as dimensions, materials, manufacturing processes, and testing. 4. Japanese Industrial Standards (JIS): JIS standards are widely used in Japan and have gained international recognition. These standards cover dimensions, materials, and testing methods for steel pipes. 5. British Standards (BS): BS standards are commonly used in the United Kingdom and cover a range of steel pipe specifications. These standards include requirements for dimensions, materials, and testing procedures. 6. American Petroleum Institute (API): API standards are specifically developed for the oil and gas industry and cover various aspects of steel pipe manufacturing. These standards include specifications for seamless and welded pipes used in oil and gas exploration, production, and transportation. It is important for manufacturers, buyers, and users of steel pipes to be aware of these standards to ensure the quality, compatibility, and reliability of the pipes. Compliance with these standards helps to ensure that the steel pipes meet the necessary requirements and are suitable for their intended applications.

- Q: What is the maximum temperature and pressure that steel pipes can withstand?

- The maximum temperature and pressure that steel pipes can withstand vary depending on the specific grade and type of steel being used. However, in general, steel pipes can withstand high temperatures and pressures due to their strong and durable nature. For high-temperature applications, such as in steam or heat transfer systems, steel pipes can typically withstand temperatures up to 1000 degrees Celsius (1832 degrees Fahrenheit) or even higher. It is important to note that the specific temperature limit may vary depending on the alloy composition and heat treatment of the steel. Regarding pressure, steel pipes are known for their excellent strength and resistance to internal and external pressure. The maximum pressure that steel pipes can withstand will depend on factors such as the pipe diameter, wall thickness, and material strength. In industrial applications, steel pipes can withstand pressures ranging from a few hundred psi (pounds per square inch) to several thousand psi. To ensure the safe operation of steel pipes under high temperatures and pressures, it is crucial to follow industry standards and guidelines, as well as perform regular inspections and maintenance. Consulting with engineers and professionals experienced in steel pipe systems can provide more specific information regarding the maximum temperature and pressure limits for a particular steel pipe application.

- Q: How are steel pipes used in the agriculture industry?

- Steel pipes are used in various ways within the agriculture industry. They are commonly used for irrigation systems, allowing water to be efficiently transported to crops. Steel pipes are also used for drainage systems, ensuring excess water is properly removed from fields. Additionally, steel pipes are used for building structures such as barns, fences, and animal enclosures, providing durability and strength.

- Q: Can steel pipes be used for fire protection systems?

- Yes, steel pipes can be used for fire protection systems. Steel pipes are commonly used in fire sprinkler systems due to their durability, strength, and resistance to high temperatures. They are capable of withstanding the heat and pressure generated during a fire, making them suitable for fire protection applications. Additionally, steel pipes can be easily connected and installed, ensuring efficient and reliable fire suppression in buildings.

- Q: What are the uses of seamless steel tubes?

- A large number of pipes used for conveying fluids, such as pipelines for transporting petroleum, natural gas, gas, water, and certain solid materials.

Send your message to us

API-5CT EUE Tubing Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000ton m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords