Able Tape Abrasion-Resistant Anti-Slip Packaging Handwrap

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 roll

- Supply Capability:

- 50000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Anti-slip Tape

1. Structure: Surface: choice anti-slip sand, rubber anti-slip fiber, sand-free special anti-slip material; Middle Layer: PET, PP, PVC and aluminum, etc. Base glue: ready-to-use waterproof strong viscose. Base paper: white/leather silicone paper.

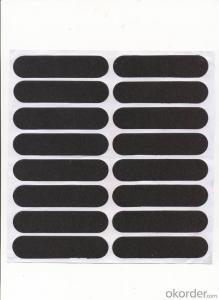

2. Appearance of Colors: Black, gray, red, orange, blue, between yellow and black, red and white, transparent, white, reflective, night light-emitting, etc. printing a variety of beautiful picture and patterns according with customer requirements.

3. Types: 1) super anti-slip 2) cozy anti-slip 3) general anti-slip 4) easy-to-clean

Application of Anti-slip Tape

1) Equipment: skateboard, scooter, running machine, exercise machine, machine tool, footplate of printing machine, passages on buses or stairways.

2) Locations: Kindergarten, school, swimming pool, nursing home, bus station, subway station, train station, pier, hotel, club house, kitchen, washing room, playground, health and recreation facilities, entrance of elevator, pedestrian slope, shopping mall, working area and deck, etc.

3) Also applicable to tourist car, ship, tow truck, truck, aircraft, hanging ladder, large- or small-sized power equipment.

Advantage of Anti-slip Tape

1.Anti-slip tape, superb tack and adhesion to surface, Strong grip that is ensured because of an excellent adhesive backing.

2. Peak performance even under extreme conditions of pressure and temperature, which can stick to all types of surfaces.

3. Consistent quality

4. on time delivery

5. Effective and timely communication

6. Competitive price

Packing of Anti-slip Tape

individually wrapped, shrink, carton.

6rolls/shrink, about 36~100rolls/carton(according to different specifications)

carton size : any carton size as your request

Pictures of Anti-slip Tape

Specification of Anti-slip Tape

| Material | PVC, PP, PE |

| Adhesive Side | Single Sided. |

| Adhesive | Acrylic, Water based acrylic adhesive. |

| Acrylic | Water based acrylic adhesive. |

| Color | Transparent clear/yellowish /tan brown/blue/red/ green |

| Normal thickness | 45mic, 46mic, 48mic,50mic, 52mic, 55mic, 60mic, 65mic, 70mic etc |

| Color | black, white, clear, blue, and print as customer’s requirment. |

| Mesh | 40# 60# 80# 100# 150# |

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

FAQ

1. What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2. What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3. How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4.Can you accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

5.What are the international commodity codes for these products?

HS Code: 48231900.

6.Are you offering only jumbos rolls or slit rolls as well?

We offer Jumbos, logs, and slit rolls. All different sizes are available.

- Q: What is the difference between acrylic and hot melt adhesive for packaging tape?

- Packaging tape commonly utilizes two types of adhesives: acrylic and hot melt. These adhesives possess distinct characteristics that set them apart. A significant disparity lies in their bonding strength. Hot melt adhesive boasts exceptional bonding strength, making it ideal for heavy-duty applications. It creates a robust and durable bond that can withstand rigorous handling and varying temperatures. Conversely, acrylic adhesive typically offers a lower level of bonding strength in comparison. While still suitable for most general packaging requirements, it may not be the best choice for heavy or bulky items. Another distinction can be found in the application process. Hot melt adhesive is applied in a molten state and solidifies once cooled. Typically, it is dispensed using a hot melt glue gun or applicator. The quick setting time of hot melt adhesive allows for swift packaging operations, making it popular in high-volume settings. On the other hand, acrylic adhesive is applied in a liquid form and requires some time to cure and establish a strong bond. It can be applied using a hand dispenser or tape gun, and optimal adhesion often necessitates some pressure. Moreover, hot melt adhesive demonstrates excellent adhesion to a wide array of surfaces, including cardboard, plastics, and metals. Its versatility allows for usage with various packaging materials. While acrylic adhesive also adheres well to different surfaces, it may not exhibit the same level of compatibility with certain low-energy surfaces, such as polyethylene or polypropylene. Furthermore, temperature resistance is an essential factor to consider. Hot melt adhesive performs admirably in both high and low temperatures, maintaining its bonding strength. It can endure freezing temperatures and heat without compromising its adhesive properties. Acrylic adhesive, while generally offering good temperature resistance, may not be as effective in extreme conditions, particularly at very high or low temperatures. In conclusion, the primary disparities between acrylic and hot melt adhesives for packaging tape lie in bonding strength, the application process, surface compatibility, and temperature resistance. While hot melt adhesive provides superior bonding strength, rapid setting time, and excellent temperature resistance, acrylic adhesive offers versatility, ease of application, and good adhesion to most surfaces. The choice between the two depends on specific packaging needs, materials used, and environmental conditions.

- Q: Can packaging tape be used for sealing plastic folders?

- Indeed, plastic folders can be sealed using packaging tape. Specifically designed to possess strength and adhesive properties, packaging tape proves apt for securing and sealing a range of materials, including plastic folders. By doing so, it aids in maintaining the security and protection of the folder's contents. Nevertheless, it is crucial to ensure the tape's proper and secure application in order to achieve a tight seal. Moreover, it is advisable to opt for a transparent packaging tape to avoid hindering the visibility of the folder's contents.

- Q: Does packaging tape have any specific certifications or standards?

- Yes, packaging tape can have specific certifications or standards. Some common certifications or standards for packaging tape include ISO 9001 (quality management), ISO 14001 (environmental management), and ASTM D1974 (standard specification for sealing and securing pressure-sensitive tape for packaging). Additionally, certain industries may have their own specific certifications or standards for packaging tape, such as food-safe certifications for packaging tape used in the food industry.

- Q: Does packaging tape come in different widths for different applications?

- Yes, packaging tape does come in different widths for different applications. Packaging tape is available in various widths ranging from as small as 0.75 inches to as wide as 3 inches or even more. The choice of width depends on the specific application and the size of the package being sealed. Smaller widths are often used for lighter weight packages or for sealing small boxes or envelopes. On the other hand, wider widths are commonly used for heavy-duty or larger boxes that require extra strength and security. The availability of different widths allows users to select the most appropriate tape size based on their specific packaging needs.

- Q: Can packaging tape be used for sealing vinyl flooring?

- It is not advisable to use packaging tape for sealing vinyl flooring. The reason being that vinyl flooring necessitates a specialized adhesive that is specifically created for flooring purposes. Opting for packaging tape might fail to offer the requisite durability and protection essential for vinyl flooring. For the best outcome, it is highly recommended to employ a vinyl flooring adhesive or a compatible adhesive as suggested by the manufacturer.

- Q: Does packaging tape come in different allergen-free options?

- Indeed, various allergen-free alternatives exist for packaging tape. Numerous manufacturers provide packaging tape that is explicitly formulated to be hypoallergenic, devoid of typical allergens like latex, gluten, and other potential irritants. These options without allergens prove especially advantageous for individuals with sensitive skin or allergies. It is highly advisable to thoroughly peruse the product labels or descriptions to guarantee that the packaging tape aligns with your precise allergen-free needs.

- Q: Can packaging tape be used for sealing cardboard boxes?

- Yes, packaging tape is commonly used for sealing cardboard boxes as it provides a strong and secure bond.

- Q: Is packaging tape resistant to punctures or tears?

- Yes, packaging tape is generally resistant to punctures or tears. It is designed to be strong and durable, specifically for securing and sealing packages. Packaging tape is made from materials such as polypropylene or polyester, which have high tensile strength and offer excellent resistance to punctures or tears. Additionally, packaging tape often has adhesive properties that further enhance its ability to withstand punctures or tears. However, it is important to note that the level of resistance may vary depending on the specific type and quality of packaging tape used.

- Q: Is packaging tape waterproof?

- Yes, packaging tape is typically waterproof. It is designed to provide a secure seal and protect packages from moisture and other external factors during transit or storage.

- Q: Is packaging tape safe to use on stainless steel?

- Yes, packaging tape is generally safe to use on stainless steel as it does not usually cause any damage or leave adhesive residue. However, it is always recommended to test a small, inconspicuous area first to ensure there are no adverse reactions or issues with the specific type of tape being used.

Send your message to us

Able Tape Abrasion-Resistant Anti-Slip Packaging Handwrap

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 roll

- Supply Capability:

- 50000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords