Aluminum Sulphate For Water Treatment Factory sales directly

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Chemical and Physical Properties:

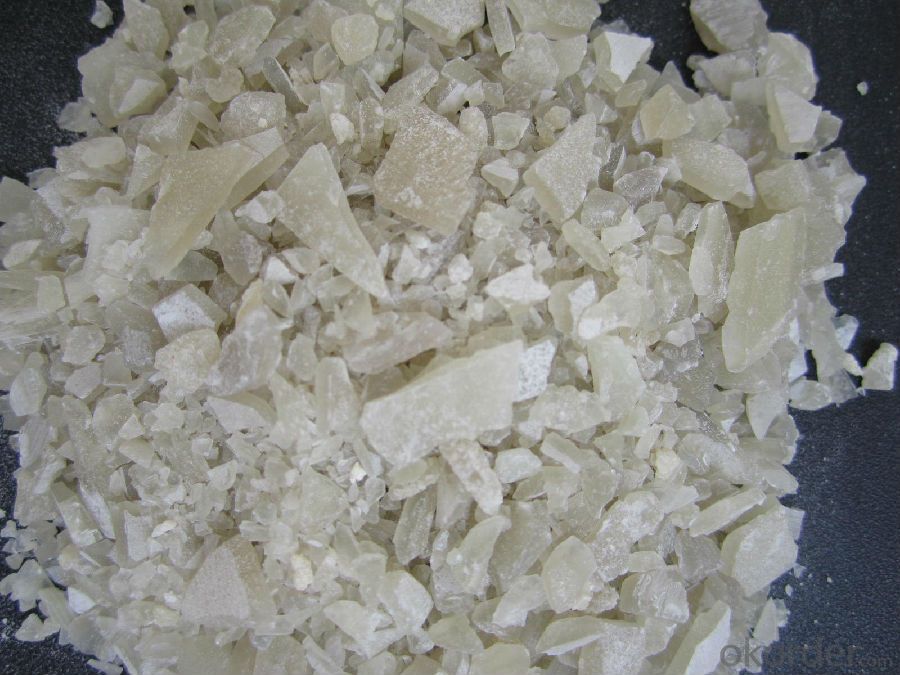

Product name: Aluminium Sulphate or Aluminum Sulfate

Shape: Flakes or Granular or Powder.

EINECS NO.:233-135-0

CAS No.: 10043-01-3

HS.Code: 28332200

Molecular Formula: Al2(SO4)3

Appearance:It is white or grey flake,particle or massive crystallization.

Apt to cake after moisture absorption when laid in air for a long time.A little green because of Fe2+ ,yellow when Fe2+ is oxided to Fe3+.Soluble in water easily,and water solution is acid.

2. Specification:

Standard: HG/T 2225-2001 and HG/T 2227-2004

Items | Specifications | |||

I Type:Low Ferrous/Low Iron | II Type:Non-Ferrous/Iron-free | |||

First Class | Qualified | First Class | Qualified | |

Al2O3 % ≥ | 15.8 | 15.6 | 17 | 16 |

Ferrous(Fe )% ≤ | 0.5 | 0.7 | 0.005 | 0.01 |

Water Insolube % ≤ | 0.1 | 0.15 | 0.1 | 0.15 |

PH (1% aqueous solution) ≥ | 3.0 | 3.0 | 3.0 | 3.0 |

Arsenic(As) %≤ | 0.0005 | 0.0005 | ||

Heavy metal (Pb) %≤ | 0.002 | 0.002 | ||

3.Applications:

Water effluent treatment system

It's used for purification of drinking water and wastewater treatment by settling of impurities by

means of precipitation and flocculation.

Paper Industry

It helps in sizing of paper at neutral and alkaline pH, thus improving paper quality (reducing spots

and holes and improving sheet formation and strength) and sizing efficiency.

Textile Industry

It is used for color fixing in Naphthol based dyes for cotton fabric.

Other Uses

Leather tanning, lubricating compositions, fire retardants; decolorizing agent in petroleum, deodorizer; food additive; firming agent; dyeing mordant; foaming agent in firefighting foams; fireproofing cloth; catalyst; pH control; waterproofing concrete; aluminum compounds, zeolites etc.

4. Package:

Packaging Detail: PP/PE 50kg/bag;25kg/bag;Jumbo bag or according to customers' requirements.

20-25MT will be loaded in per 20'FCL container.

5. Attention and Storage:

The product is liable to absorb moisture and clot due to long-term exposure, so shady, cool and ventilated environment is needed.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: how could scientists know the exact catalyst for every reactions??? THANX sooo much

- Believe me, nema, there's no way that we chemists know the best catalyst for every reaction. That would be simply impossible. However, from the type of reaction, the reactants, products, reaction conditions, solvents, etc. and from one's experience and the literature (papers and patents) one can get a good idea for most reactions of the type of catalyst that has worked for similar systems. One then starts off with a catalyst from the literature and modifies or changes it if improvement is needed based on chemical principles that one learns. There are also some theoretical calculations that can be made. Sometimes they work and sometimes they don't :) If it is an industrially important process like the Haber process for making ammonia from nitrogen gas and hydrogen gas, there may be thousands of catalysts which have been tried and evaluated. New minor improvements are being made every day. When a company does find a very good catalyst for an important reaction, often they keep it a trade secret. The good catalyst can make a huge difference in how commercially successful a particular process is. That's a large part of what chemical engineers do. You may never know if you have the best catalyst. The most you can hope for is one that is good enough. So it's a few parts personal knowledge, a few parts literature, a couple of parts theory, a lot of experimentation and often, more than not, a little luck. :)

- Q: What is the catalyst condition in the chemical equation?

- Do you want to play on your computer? Trouble ah ~ no you add brackets it ~ word may be able to try ~ I have not studied ~ now look ~

- Q: What is the catalyst for ethylene addition water? How to play a catalytic role.

- Phosphoric acid or sulfuric acid, 280 to 300 ° C, 7 to 8 MPa

- Q: explain how a catalyst can affect the rate of reaction but not be in the overall equation.?

- a catalyst is a substance that speeds up the rate of reactions that would already happen (the reactions are spontaneous) but would take a long long time to occur. Every reaction proceeds from a level of high energy to a lower level of energy, but in order to start going downhill you need to get up, in affect getting more energy than the reactants have now. This is because the transition state, or what the reactnat/product is in the middle of the reaction, is less stable and requires more energy than the reactants. Catalysts lower the extra energy needed (called activation energy) to a level that the reactants already have, and the reaction occurs.

- Q: Is it possible for the different chemical reactions to have the same catalyst?

- Just as manganese dioxide can catalyze the decomposition of molten potassium chlorate can catalyze the decomposition of hydrogen peroxide, but this is not necessarily the same as the catalyst for the production of the same product, but for the enzyme in order to ensure that the growth of the orderly all have a single Enzymes can only catalyze an organic matter

- Q: Can manganese dioxide be used as a catalyst for various chemical reactions?

- Manganese dioxide can be a catalyst for hydrogen peroxide decomposition, a catalyst for the preparation of chlorine gas from potassium chlorate, and the like can be reactants

- Q: what is the difference between enzyme and catalyst?

- Enzymes and catalysts both affect the rate of a reaction. The difference between catalysts and enzymes is that while catalysts are inorganic compounds, enzymes are largely organic in nature and are bio-catalysts. Even though all known enzymes are catalysts, all catalysts are not enzymes. Moreover, catalysts and enzymes are not consumed in the reactions they catalyze. Catalysts are low molecular weight componds, enzymes are high molecular globular proteins. Catalysts are inorganic, enzymes are organic. Catalyst reaction rates are slower (usually) than enzyme reaction rates. Catalysts are not generally specific - enzymes are VERY specific. Catalysts increase or decrease the rate of a chemical reaction, enzymes are proteins that incrase the rate of chemical reactions & convert the substrate into product. There are 2 types of catalysts - (positive & negative), and the 2 types of enzymes are activation enzymes and inhibitory enzymes. Catalysts are simple inorganic molecules, while enzymes are complex proteins.

- Q: Why extract the genome, the digestion is always not cut

- The enzyme, like the general catalyst, only catalyzes the thermodynamics of the permissible chemical reaction, shortening the time to reach the chemical equilibrium without changing the equilibrium point. The enzyme as a catalyst has no qualitative and quantitative changes before and after the chemical reaction. The mechanism of action of enzymes and general catalysts is to reduce the activation energy of the reaction.

- Q: Several experiments were carried out using catalysts

- Hydrogen peroxide in the manganese dioxide as a catalyst for decomposition reaction: 2H2O2 == MnO2 == 2H2O + O2 ↑ (laboratory oxygen principle)

- Q: Chemistry: Does the catalyst participate in the reaction?

- The catalyst does not participate in the reaction, except that the reaction rate is changed.

Send your message to us

Aluminum Sulphate For Water Treatment Factory sales directly

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords