Aluminum strip for dry type transformer winding 1050/1060/1050A aluminum strip manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum strip for dry-type transformer windings is mainly made of aluminum ingots after smelting and rolling and slitting. It uses high-quality pure aluminum as raw material. Common grades include 1060, 1050, 1050A, 1070, 1070A, 1350, etc. The state is usually O state (indicating soft state).

Advantages of aluminum strip for dry-type transformer windings:

Reduced cost: The price of aluminum is lower than that of copper. The use of aluminum strip significantly reduces the manufacturing cost of transformers, especially large equipment.

Light weight: The density of aluminum is one-third of that of copper. Aluminum strip windings make transformers lighter and facilitate transportation and installation.

Good corrosion resistance: An aluminum oxide layer is formed on the surface of aluminum, which can reduce corrosion and extend service life.

Flexible design: Aluminum strips can increase the cross-sectional area, and the conductivity is comparable to that of copper windings, making design and manufacturing more flexible.

Specifications of aluminum strips for dry transformers:

| Alloy | 1060, 1050, 1050A, 1070, 1070A, 1350, etc |

| Temper | H14, H16, H18, H24, H26, O |

| Thickness | 0.2-3.0mm |

| Width | 20-1650mm |

| Length | 1000-16000mm |

| ID | 75mm, 150mm |

| Application | Narrow width aluminum strips can be used for automotive radiators, transformers, and other industrial applications. |

| Packaging | Standard export wooden box |

| MOQ | 1-3 tons |

| HS Code | 7606920000 |

Why choose transformer aluminum strips produced by MC Aluminum?

1. The surface of the aluminum strip should be smooth, flat, free of burrs, oil stains and dust.

2. Defects such as corrosion, oil spots, cracks, cracked edges, bubbles, holes, etc. are not allowed.

3. The surface coating of the aluminum strip (if any) should be uniform and firm, without peeling, cracking, etc.

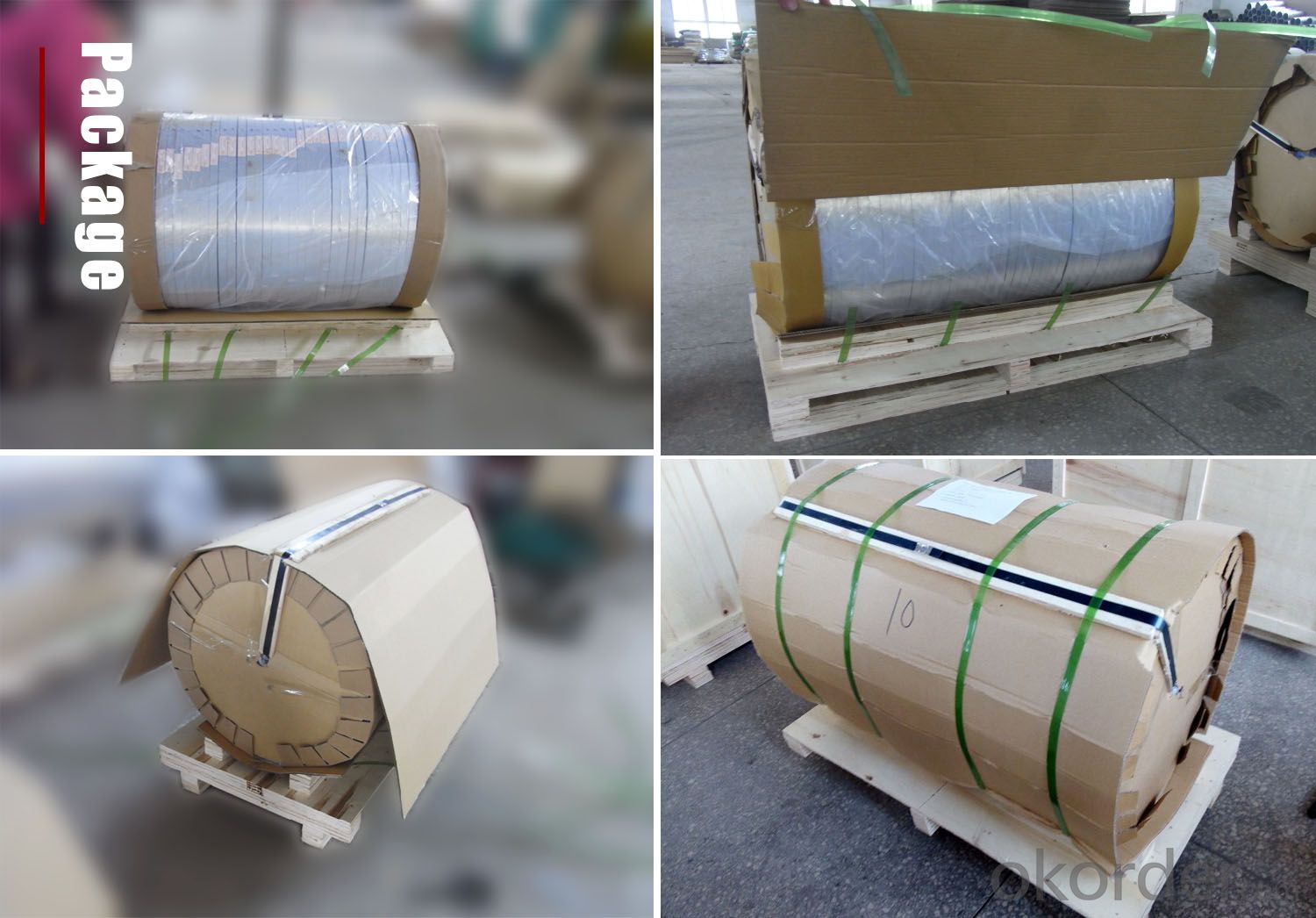

Packaging:

Packing: Sea-resistant wooden pallets. In addition, we can also pack according to customer requirements.

Loading port: Qingdao, Tianjin, Ningbo, Shanghai, Guangdong, etc.

(1) For coils/strips, you can choose eye-to-ceiling or eye-to-wall packaging;

(2) For plates, use wooden pallets with fixing straps for sea transportation;

(3) Standard wooden pallets or wooden boxes are used for sea transportation;

(4) Special packaging requirements can be customized.

- Q: This question asks for a comparison of the pros and cons associated with the use of aluminum strips in roofing systems.

- <p>Aluminum strips in roofing offer several advantages such as durability, resistance to corrosion and rust, lightweight nature, and low maintenance requirements. They are also energy-efficient, reflecting heat and reducing cooling costs. Additionally, aluminum strips can be easily recycled, contributing to environmental sustainability. However, there are downsides, including higher initial costs compared to other roofing materials and potential for denting if not properly installed or maintained. Aluminum can also be noisy during rain, and may require more frequent replacement due to its lighter gauge compared to some other materials.</p>

- Q: This question asks if it is permissible to use recycled metal sheets in construction within the user's specific geographical area.

- <p>The legality of using recycled metal sheets in construction projects varies by region and state. It is essential to consult local building codes and regulations, as they dictate the acceptable materials for construction. Some areas may have strict guidelines regarding the use of recycled materials due to concerns over structural integrity and safety. In other regions, there may be incentives or regulations promoting the use of recycled materials for environmental and sustainability reasons. Always check with your local building department or consult a construction professional to ensure compliance with all applicable laws and codes.</p>

- Q: What benefits does aluminum provide compared to other metals when used for roofing applications?

- <p>Aluminum offers several advantages for roofing, including its lightweight nature, which reduces structural load. It is highly resistant to corrosion, making it suitable for various climates and environments. Aluminum's malleability allows for easy shaping and forming, enabling complex designs. It also has excellent reflectivity, which can help in reducing heat absorption and improving energy efficiency. Additionally, aluminum is recyclable and has a lower environmental impact compared to some other metals. These properties make aluminum a popular choice for roofing materials.</p>

- Q: Is it possible to utilize aluminum strips in outdoor settings?

- <p>Yes, aluminum strips can be used for outdoor applications. They are known for their corrosion resistance, making them suitable for outdoor environments where they may be exposed to various weather conditions. Aluminum's durability and lightweight properties also make it a popular choice for outdoor construction and decoration. However, it's important to ensure that the aluminum is properly treated or coated to enhance its resistance to weathering and maintain its appearance over time.</p>

- Q: This question asks for advice on choosing high-quality aluminum strip roofing materials.

- <p>When selecting quality aluminum strip roofing materials, consider the following tips: 1. Gauge Thickness: Opt for a thicker gauge for increased durability and resistance to weathering. 2. Coating: Look for materials with a protective coating, such as Kynar 500 or Hylar 5000, which offer superior resistance to fading and chalking. 3. Color Options: Choose materials with a wide range of color options to match your home's aesthetic. 4. Energy Efficiency: Select materials with high solar reflectance to reduce cooling costs. 5. Manufacturer Reputation: Research the reputation of the manufacturer for quality and reliability. 6. Certifications: Ensure the materials meet industry standards and certifications, such as the American Society for Testing and Materials (ASTM). 7. Warranty: A good warranty is a sign of confidence in the product's quality and longevity. 8. Installation: Consider the ease of installation and whether the material requires specialized tools or techniques.</p>

- Q: Is it possible to utilize recycled nails or screws for the installation of aluminum strips?

- <p>Yes, you can use recycled nails or screws to install aluminum strips, provided they are in good condition and compatible with the material. Ensure the recycled fasteners are clean, rust-free, and have no damage that could affect their holding power. It's also important to use the correct size and type of nails or screws suitable for the thickness and type of aluminum strips you are installing. Always follow safety precautions and use appropriate tools to prevent injury.</p>

- Q: What characteristics of aluminum strips make them an ideal material for roofing purposes?

- <p>Aluminum strips are suitable for roofing due to their lightweight nature, which reduces structural load. They offer excellent corrosion resistance, protecting against rust and decay, and are highly durable, maintaining their integrity for decades. Aluminum's malleability allows for easy shaping into various profiles, enhancing design flexibility. Additionally, aluminum strips reflect heat well, reducing energy consumption for cooling, and they are recyclable, contributing to environmental sustainability.</p>

- Q: What kind of aluminum strip is most suitable for use in flooring applications?

- <p>The best type of aluminum strip for flooring is typically one that is durable, slip-resistant, and resistant to corrosion. Anodized aluminum strips are often preferred due to their strength, wear resistance, and ability to withstand heavy foot traffic. They also offer a sleek, modern aesthetic and can be used in various flooring applications, including commercial and residential settings. The thickness and width of the strip can vary depending on the specific requirements of the project, but a common choice is a 1mm to 3mm thick strip for stability and support.</p>

- Q: The user is asking whether they should hire a professional to install aluminum strip products or if they can do it themselves.

- <p>Whether to hire a professional or do it yourself depends on your experience and comfort level with DIY projects. If you are skilled in construction or have experience with similar installations, you may be able to install aluminum strip products yourself. However, if you lack the necessary skills or are unsure about the process, hiring a professional installer is recommended. Professionals have the expertise to ensure a proper and secure installation, which can save you time and potential complications down the line. Additionally, they can handle any unexpected issues that may arise during the installation process.</p>

- Q: What specific cleaning techniques should be employed for maintaining an aluminum strip roof?

- <p>When cleaning an aluminum strip roof, it's important to use gentle cleaning methods to avoid damaging the metal. Use a soft brush or broom to remove debris and avoid using abrasive tools that could scratch the surface. For cleaning solutions, opt for mild detergents mixed with water, and avoid harsh chemicals that could corrode the aluminum. Always rinse thoroughly to remove any residue. Never use high-pressure water or steam cleaners, as they can cause dents or warp the aluminum. Regular maintenance, such as checking for and sealing any leaks, will also help prolong the life of your aluminum strip roof.</p>

Send your message to us

Aluminum strip for dry type transformer winding 1050/1060/1050A aluminum strip manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Related keywords