Aluminum Pipes Wooden Coating Aluminium Coils for Rolling Shutter Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Wooden Coating Aluminium Coils for Rolling Shutter Doors

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Wooden Coating Aluminium Coils for Rolling Shutter Doors

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels, column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Wooden Coating Aluminium Coils for Rolling Shutter Doors

• Our goods quality is top, the surface is smooth, and every steel coil

• No Joint, No Bends, no spots, no roller marks.

• MTC will be provided with goods, third part inspection is acceptable, for example, SGS, BV. Etc

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

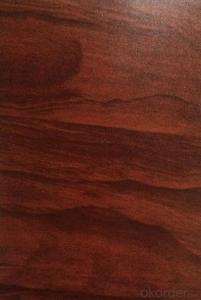

5. Image of Wooden Coating Aluminium Coils for Rolling Shutter Doors

6. Package and shipping of Wooden Coating Aluminium Coils for Rolling Shutter Doors

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Need to know the answer urgently. If anyone knows, please answer, thank you.........Supplement: aluminum without primer spraying, spray and spray paint, paint is 22 dilute acid. After spraying up, adhesion is good, not easy to fall, what formula, or in paint which need to add what?

- The main consideration of painting on aluminum is the adhesion between primer and aluminum. In general, the market is more use of phosphating primer, phosphating primer is a sacrificial paint (will cause damage to the base material), and the high requirements of adhesion performance is not ideal.Also, the base coat is made of ordinary epoxy resin, and the adhesive force is rather weak.At present, relatively strong adhesion paint, 100 meter test can reach 100%, in China only a few foreign paint production enterprises.

- Q: Can aluminum tube and stainless steel pipe be welded directly?

- If the direct use of other auxiliary welding material can be, but I would also like to know whether the current technology can use laser welding, aluminum and stainless steel?

- Q: Are aluminum pipes suitable for underground cable conduits?

- Yes, aluminum pipes are suitable for underground cable conduits. Aluminum is a lightweight and durable metal that is resistant to corrosion, making it an excellent choice for underground applications. It is also a cost-effective option compared to other materials like steel or copper. Additionally, aluminum pipes have good thermal conductivity, which helps dissipate heat generated by the cables. Proper insulation and installation techniques ensure that the cables are protected and the underground conduit system functions efficiently.

- Q: I have 6 60CM long diameter 5MM aluminum tubes, which are used on the model. I want to take it home. It is too small for me to take a plane. Can I take it with me? For advice, fly from Nanjing, transfer in Xi'an, check security two times.

- In general can not carry only checked, you can specify at check-in, see if you can carry, if not, the airport where there are special packing, good consignment packaging.

- Q: Can aluminum pipes be used for irrigation pivot systems?

- Yes, aluminum pipes can be used for irrigation pivot systems. Aluminum is a popular choice for irrigation systems due to its lightweight nature, corrosion resistance, and durability. Aluminum pipes are easy to handle and install, making them suitable for pivot systems that require flexibility and easy maneuverability. Additionally, aluminum pipes have a long lifespan and can withstand harsh weather conditions, making them a reliable choice for irrigation pivot systems. However, it is important to consider the specific requirements of the irrigation system and consult with experts to ensure that the chosen materials, including aluminum pipes, are suitable for the specific application.

- Q: Can aluminum pipes be used for underground drainage systems?

- Yes, aluminum pipes can be used for underground drainage systems. Aluminum is a lightweight, durable, and corrosion-resistant material, making it suitable for various applications, including underground drainage systems. Aluminum pipes are commonly used in these systems due to their ability to withstand harsh environmental conditions, such as moisture and soil acidity. Additionally, aluminum pipes are easy to install, maintain, and repair, making them a cost-effective choice for underground drainage systems. However, it is important to ensure that the aluminum pipes are properly coated or protected to prevent any potential reactions with soil or water that could compromise their integrity.

- Q: Where does the refrigerator copper tube come from? How to distinguish

- Is the pipe next to the compressor copper?Chasing the answerIs this tube above connected to the tube in the refrigerator sealed with it, see.

- Q: Are aluminum pipes suitable for chemical processing plants?

- Yes, aluminum pipes can be suitable for chemical processing plants depending on the specific requirements and conditions of the plant. Aluminum pipes offer several advantages for chemical processing applications. Firstly, aluminum is lightweight, making it easier to handle and install compared to other materials such as steel. This can help reduce labor and transportation costs during installation. Additionally, aluminum pipes have good corrosion resistance properties, which is crucial in chemical processing plants where exposure to various corrosive chemicals is a common occurrence. Aluminum naturally forms a protective oxide layer on its surface, which helps prevent further corrosion and degradation. This oxide layer can be further enhanced through various surface treatments to improve the resistance to specific chemicals. Moreover, aluminum pipes have excellent thermal conductivity properties, allowing for efficient heat transfer in chemical processes that involve heating or cooling. This can contribute to energy savings and more efficient operations. However, it is important to note that aluminum pipes may not be suitable for all chemical processing applications. Aluminum can react with certain aggressive chemicals or extreme conditions, such as high temperatures or extreme pH levels. In such cases, alternative materials like stainless steel or specialty alloys may be more appropriate. Therefore, before using aluminum pipes in a chemical processing plant, it is essential to thoroughly evaluate the specific requirements, chemicals involved, operating conditions, and consult with experts or engineers to determine their suitability and any necessary precautions or limitations.

- Q: Who knows there is a high mountain reed 2plus short tube is what? Urgent!

- A short tube called first aid tent pole, or emergency fault rod, when you appear in the outdoor pole fracture, but also can not be repaired, you can use the emergency fault bar is set in place, so you can still set up the tent,

- Q: What are the insulation requirements for aluminum pipes in cold climates?

- In cold climates, aluminum pipes require insulation to prevent heat loss and ensure efficient operation of the system. The specific insulation requirements for aluminum pipes in cold climates depend on factors such as the temperature range, the type of fluid being transported, and the intended use of the pipes. One of the main purposes of insulation for aluminum pipes in cold climates is to prevent condensation. When the temperature of the pipe surface falls below the dew point, moisture in the air can condense on the pipe, leading to corrosion and potentially compromising the integrity of the system. Insulation helps maintain the surface temperature above the dew point, preventing condensation and protecting the pipes from damage. The insulation material for aluminum pipes in cold climates should have a high thermal resistance or R-value to minimize heat transfer and maintain the desired temperature of the fluid being transported. Common insulation materials used for this purpose include mineral wool, fiberglass, polyurethane foam, and cellular glass. These materials provide excellent thermal insulation properties and can be applied in various forms, such as pre-formed sections, blankets, or spray-on coatings. The thickness of the insulation layer is determined by the desired level of thermal resistance and the specific requirements of the system. It is important to consult local building codes and standards to ensure compliance with the recommended insulation thickness for aluminum pipes in cold climates. Additionally, the insulation should be properly sealed and protected to prevent moisture ingress, which could reduce its insulating effectiveness. In addition to thermal insulation, aluminum pipes in cold climates may also require additional measures such as heat tracing or electric heating cables to maintain the temperature of the fluid when the ambient temperature drops significantly. These systems provide an extra layer of protection against freezing and ensure the continuous operation of the system. Overall, the insulation requirements for aluminum pipes in cold climates involve selecting the appropriate insulation material, determining the necessary thickness, and considering additional measures to maintain the desired temperature. It is crucial to consult with experts or professionals in the field to ensure that the insulation meets the specific needs of the system and complies with relevant regulations.

Send your message to us

Aluminum Pipes Wooden Coating Aluminium Coils for Rolling Shutter Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords