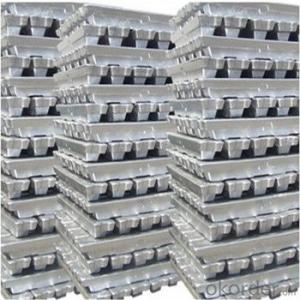

Aluminum Ingots AA5052

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Sets Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1. Specifications of Aluminum Ingots AA5052

| Product Name | Aluminum Ingot |

| Chemical Composition | Al |

| Weight | 20/25kg |

| Al (Min) | 99%-99.9% |

| Appearance | silvery white |

| Advantages | easy control and operation, fast melting |

2. Usage/Application of Aluminum Ingots AA5052

A. mainly used for melting ingot

B. discontinuous melting with scrap

3.Packaging & Delivery of Aluminum Ingots AA5052

About 25Kg /Ingot, Packed in wooden case, Net weight 1000Kg/ Case, or as customer's requirements.

- Q: The difference between electrolytic aluminium, alumina and aluminium ingot

- Two the production process is different, one is from bauxite by a series of chemical reactions, to aluminum hydroxide, then baking system of alumina, electrolytic aluminum is alumina powder electric melting, electrolytic aluminum ingot.

- Q: What are the different forms of aluminum ingots available in the market?

- There is a wide range of aluminum ingots available in the market, each designed to cater to specific needs in various industries. The commonly found types are as follows: 1. Primary Aluminum Ingots: These ingots are produced by electrolytically reducing alumina, resulting in high-purity aluminum. They find applications in manufacturing processes across industries such as automotive, aerospace, and construction. 2. Secondary Aluminum Ingots: Made from recycled aluminum scrap, these ingots undergo melting and refining before being cast. They are cost-effective and environmentally friendly, making them popular in industries like packaging, electronics, and consumer goods. 3. Alloyed Aluminum Ingots: By adding specific alloying elements like copper, silicon, or magnesium during smelting or casting, these ingots offer improved mechanical properties, corrosion resistance, and other desired characteristics. They are used in applications like automotive parts, aircraft components, and building materials. 4. High-Purity Aluminum Ingots: These ingots are manufactured with exceptionally high levels of purity, often exceeding 99.99%. They are primarily used in industries that require ultra-clean and low-contamination materials, such as electronics, semiconductors, and solar panels. 5. Cast Aluminum Ingots: Produced through the casting process, molten aluminum is poured into molds and allowed to solidify, creating versatile ingots that can be further processed into different shapes and sizes. They are suitable for industries like automotive, construction, and marine. It is important to note that the availability of these aluminum ingot forms may vary depending on the specific market and region. Additionally, each type has its own advantages, disadvantages, and applications. Therefore, it is crucial to choose the appropriate form based on the intended use and requirements.

- Q: What are the advantages of using aluminum ingots in the production of medical devices?

- There are several advantages of using aluminum ingots in the production of medical devices. Firstly, aluminum is a lightweight metal, making it ideal for medical devices that need to be portable and easy to handle. It reduces the overall weight of the device, making it more comfortable for patients and easier for healthcare professionals to use. Secondly, aluminum has excellent corrosion resistance properties. This is crucial in medical devices as they often come into contact with various bodily fluids and chemicals. By using aluminum ingots, manufacturers can ensure that the medical devices will not corrode or degrade over time, thus increasing their lifespan and reliability. Additionally, aluminum is highly malleable and can be easily shaped and formed into intricate designs. This allows for the production of complex medical devices with precise specifications. The versatility of aluminum ingots enables the creation of devices that can fit various anatomical structures, ensuring a better fit and improved functionality for patients. Furthermore, aluminum is a non-toxic material and does not react with human tissues. It is biocompatible, meaning it can be safely used in medical devices that come into direct contact with the body, such as implants, surgical instruments, and prosthetics. Aluminum's biocompatibility reduces the risk of adverse reactions or complications for patients. Lastly, aluminum ingots are cost-effective compared to other metals commonly used in medical device production. The abundance of aluminum ore and its relatively low cost of extraction make it a more affordable option for manufacturers. This cost-effectiveness can lead to more accessible medical devices, benefiting patients and healthcare systems worldwide. In conclusion, the advantages of using aluminum ingots in the production of medical devices include their lightweight nature, excellent corrosion resistance, malleability, biocompatibility, and cost-effectiveness. These properties make aluminum a suitable choice for creating high-quality, durable, and safe medical devices.

- Q: Aluminum is pure aluminum expensive, or aluminum alloy expensive, aluminum ingot expensive, aluminum just expensive

- Aluminum ingots are cheap, followed by pure aluminum, and then aluminium alloys

- Q: How are aluminum ingots used in the production of modular buildings?

- Aluminum ingots are used in the production of modular buildings as they are melted and formed into various structural components such as beams, columns, and panels. These ingots are particularly beneficial due to their lightweight yet strong nature, making them ideal for constructing durable and easily transportable modular buildings. Additionally, aluminum's resistance to corrosion ensures the longevity and low maintenance of the structures.

- Q: What are the properties of aluminum ingots?

- Aluminum ingots possess several distinct properties that make them highly valuable in various industries. First and foremost, aluminum ingots exhibit exceptional lightness, as they have a low density compared to other metals. This property makes them ideal for applications where weight reduction is crucial, such as in the aerospace and automotive sectors. Additionally, aluminum ingots possess excellent corrosion resistance, making them suitable for use in environments where exposure to moisture, chemicals, or harsh weather conditions is probable. This corrosion resistance is due to the formation of a thin, protective oxide layer on the surface of the ingot, which prevents further oxidation and deterioration. Another notable property of aluminum ingots is their high thermal conductivity, allowing them to efficiently transfer heat. This characteristic is particularly advantageous in heat exchange systems, where the ingots can facilitate the transfer of thermal energy. Moreover, aluminum ingots also exhibit excellent electrical conductivity, making them suitable for applications in the electrical and electronics industries. Furthermore, aluminum ingots have a high strength-to-weight ratio, making them strong yet lightweight. This property allows for the construction of structures that require both strength and durability without compromising on weight. Moreover, aluminum ingots are easily recyclable, retaining their properties even after multiple recycling processes, which makes them an environmentally friendly choice. Overall, the properties of aluminum ingots, including their lightness, corrosion resistance, thermal and electrical conductivity, high strength-to-weight ratio, and recyclability, contribute to their widespread use in various industries, ranging from transportation and construction to packaging and consumer goods.

- Q: Want to melt the cans into aluminium ingots, but what about iron cans?

- Silver light metal. Ductility. Goods are often made in bars, sheets, foils, powders, ribbons, and filaments. A layer of oxide film that prevents metal corrosion is formed in moist air. Aluminum powder and aluminum foil heated in the air can burn violently and give a dazzling white flame. Soluble in dilute sulfuric acid, nitric acid, hydrochloric acid, sodium hydroxide and potassium hydroxide solution, insoluble in water. Relative density 2.70. Melting point 660 DEG C. Boiling point 2327 DEG C.

- Q: How about aluminium material?

- Connaught scale is still OK, belong to cutting-edge, old trees send new shoots, they are from the aluminum out, the bird's nest is responsible for aluminum

- Q: Why is there a lot of glue after the aluminium ingot is melted?

- You were being set up (ingot tundish ash, suggest that you get some cut sampling, look at the middle consistency). It is a greater loss, only the ash picked up, and then put the iron pot with sodium nitrate, pulverized coal stir, the question raised by this al DNA. The most after I have a advice, please do not use zinc chloride, it is toxic, a few days down near all the plants will die, will seriously affect the health!

- Q: What kinds of aluminum alloy material are used in casting?

- Aluminum profiles are widely used in furniture: screens, skeletons, various kinds of suspension beams, tables, feet, decorative strips, handles, winding grooves and covers, chairs, tubes and so on. They can be designed and used in a variety of ways!

We are a well-known enterprise specializing in the production and sales of aluminum sheets and coils.

Since the establishment of us, we have been devoted to setting up a good CIS and completely implementing ISO9001 quality management system.

1. Manufacturer Overview

| Location | Henan,China |

| Year Established | 1993 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Ingots AA5052

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Sets Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords