Aluminum Pig/Ingot Best Seller 201 From China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pure Aluminum Pig/Ingot Used for Industry

1.Structure of Aluminum Pig/Ingot

A material that has been cast into a shape in order to be transported and processed easier than in an unprocessed form. An ingot is typically rectangular in shape, which allows it to be stacked. Ingots are most commonly associated with metals, with ingots of gold held in the vaults of banks and brokerages being popular images.

Aluminum Ingot is with the AL as the main chemical composition.Aluminum Ingot is used for industry,such as automobile,pinning and weaving,electron broadly and so on. Aluminum Ingot has the following advantages: easy control and operation, fast melting.

2.Main Features of the Aluminum Pig/Ingot

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

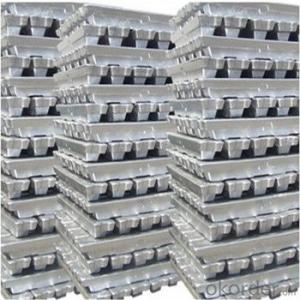

3.Aluminum Pig/Ingot Images

4.Aluminum Pig/Ingot Specification

Grade | Chemical Composition % | |||||||||

Al≥ | impurities ≤ | |||||||||

Si | Fe | Cu | Ga | Mg | Zn | Mn | others | Sum | ||

Al99.9 | 99.90 | 0.50 | 0.07 | 0.005 | 0.02 | 0.01 | 0.025 | - | 0.010 | 0.10 |

Al99.85 | 99.85 | 0.80 | 0.12 | 0.005 | 0.03 | 0.02 | 0.030 | - | 0.015 | 0.15 |

Al99.7 | 99.70 | 0.10 | 0.20 | 0.010 | 0.03 | 0.02 | 0.030 | - | 0.030 | 0.30 |

Al99.6 | 99.60 | 0.16 | 0.25 | 0.010 | 0.03 | 0.03 | 0.030 | - | 0.030 | 0.40 |

Al99.5 | 99.50 | 0.22 | 0.30 | 0.020 | 0.03 | 0.05 | 0.050 | - | 0.030 | 0.50 |

Al99.00 | 99.00 | 0.42 | 0.50 | 0.020 | 0.03 | 0.05 | 0.050 | - | 0.050 | 1.00 |

5.FAQ of Aluminum Pig/Ingot

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A professional manufacturers of the alumiun pig.Devoted in this industry for many years,so got much experice.The quality and service have also accepted by customer.Can meet customers' requiements to provide different grade and purity alumiun pig.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the prod rking days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How are aluminum ingots melted?

- Aluminum ingots are melted using a process called smelting, which involves heating the ingots in a furnace until they reach their melting point of around 660 degrees Celsius. This heat causes the ingots to liquefy and become molten aluminum, which can then be further processed and used in various industries.

- Q: How to make aluminium box into aluminium ingot?

- The problem of aluminum is not high. It can be dissolved directly in a dry pan, but it should not be dissolved directly because the aluminum ingot is pure aluminum, and the aluminum case should have impurities.The smoke isn't too big.

- Q: How are aluminum ingots used in the production of electrical enclosures?

- Aluminum ingots are used in the production of electrical enclosures as they are melted down and cast into specific shapes and sizes to create the main body of the enclosure. The ingots provide the necessary raw material for the enclosure's construction, offering strength, durability, and corrosion resistance. Additionally, aluminum ingots can be easily formed, machined, and welded, allowing for the creation of intricate designs and precise dimensions required for electrical enclosures.

- Q: How are aluminum ingots used in the production of furniture?

- Aluminum ingots are utilized in the production of furniture in various ways. Firstly, aluminum ingots serve as a primary raw material for the creation of lightweight and durable furniture frames. The ingots are melted down and cast into desired shapes and sizes, forming the skeleton or structure of the furniture piece. Once the aluminum frame is formed, it undergoes further processing, such as cutting, bending, and welding, to achieve the desired design and functionality. This allows for the creation of intricate and modern furniture designs that are both aesthetically pleasing and functional. Additionally, aluminum ingots are commonly used in the production of outdoor furniture due to their excellent corrosion resistance properties. Outdoor furniture is exposed to harsh weather conditions, and aluminum's natural resistance to rust and deterioration makes it an ideal choice for such applications. Moreover, aluminum ingots can be used to create various components of furniture, such as legs, armrests, and decorative elements. These components are then assembled with other materials, such as wood, glass, or fabric, to create the final furniture product. The use of aluminum ingots in furniture production offers numerous advantages. Aluminum is lightweight, making the furniture easy to move and rearrange. It also provides exceptional strength and durability, ensuring the longevity of the furniture piece. Furthermore, aluminum is a highly recyclable material, making it an eco-friendly choice for furniture manufacturing. In conclusion, aluminum ingots play a crucial role in the production of furniture. They are transformed into frames, components, and decorative elements, providing lightweight, durable, and stylish furniture options. The versatility and sustainability of aluminum make it a preferred choice for furniture manufacturers, especially for outdoor and modern designs.

- Q: The difference between pure aluminium ingot and aluminium alloy ingotToday I know, aluminum ingot is also divided into pure aluminum ingot, aluminum alloy ingot, what is the difference between them?

- Aluminum Alloy: YISHION and recovery of aluminum ingot aluminum as raw material, in accordance with international standards or special requirements add other elements, such as: GUI (Si), copper (Cu), magnesium (Mg), iron (Fe)... To improve the casting, chemical and physical properties of pure aluminum. The alloy is suitable for casting and can make the casting work well

- Q: How are aluminum ingots used in the production of bicycles?

- Aluminum ingots play a crucial role in the production of bicycles as they are the primary material used to manufacture bicycle frames. Aluminum is a lightweight and durable metal, making it ideal for creating strong yet lightweight frames. To produce bicycle frames, aluminum ingots are first melted down and then poured into molds to form the desired shape. The molten aluminum is allowed to cool and solidify, resulting in a solid ingot in the shape of the frame. These aluminum ingots are then further processed through various techniques such as extrusion or hydroforming to shape them into tubes or other desired forms. The tubes are cut, welded, and joined together to create the frame structure of the bicycle. Aluminum ingots are preferred in bicycle manufacturing due to their exceptional strength-to-weight ratio. This allows for a lighter bicycle that is easy to handle and maneuver, while still providing the necessary strength and rigidity for support. Additionally, aluminum ingots offer excellent corrosion resistance, ensuring that the bicycle frames can withstand harsh weather conditions and last for a longer period. This feature is especially important for bicycles as they are often exposed to outdoor elements. Furthermore, aluminum ingots enable manufacturers to create frames with intricate designs and shapes, providing opportunities for customization and innovation in bicycle design. In summary, aluminum ingots are integral to the production of bicycles as they are used to create lightweight, durable, and corrosion-resistant frames. Their versatility and strength make them a preferred choice for manufacturers, contributing to the overall quality and performance of bicycles.

- Q: What is the melting point of aluminum ingots?

- The melting point of aluminum ingots is approximately 660 degrees Celsius or 1220 degrees Fahrenheit.

- Q: Analysis of die casting aluminium ingot

- Non standard ingot ingredients as follows. (general non-standard zinc die-casting aluminum ingot will exceed the standard in 2-3, such as: Japan) ADC12Z (zinc below 3) silicon slightly low, other elements are close to ADC12. (GB aluminum standard available, here no longer).

- Q: What are the different surface finishes available for aluminum ingots?

- The different surface finishes available for aluminum ingots include mill finish, brushed finish, anodized finish, powder-coated finish, and polished finish.

- Q: Can aluminum ingots be welded?

- Yes, aluminum ingots can be welded.

Send your message to us

Aluminum Pig/Ingot Best Seller 201 From China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches