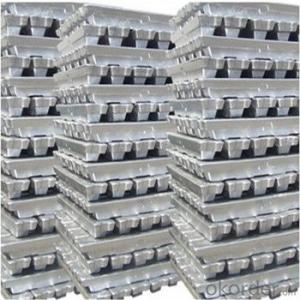

Aluminum Ingots AA3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Sets Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of Aluminum Ingots AA3003 Product Name Aluminum Ingot Chemical Composition Al Weight 20/25kg Al (Min) 99%-99.9% Appearance silvery white Advantages easy control and operation, fast melting Chemical composition of Aluminum Ingots AA3003 Grade Chemical Composition % Al≥ Si Fe Cu Ga Mg Zn Mn others Sum Al99.9 99.90 0.50 0.07 0.005 0.02 0.01 0.025 - 0.010 0.10 Al99.85 99.85 0.80 0.12 0.005 0.03 0.02 0.030 - 0.015 0.15 Al99.7 99.70 0.10 0.20 0.010 0.03 0.02 0.030 - 0.030 0.30 Al99.6 99.60 0.16 0.25 0.010 0.03 0.03 0.030 - 0.030 0.40 Al99.5 99.50 0.22 0.30 0.020 0.03 0.05 0.050 - 0.030 0.50 Al99.00 99.00 0.42 0.50 0.020 0.03 0.05 0.050 - 0.050 1.00 2. Usage/Application of Aluminum Ingots AA3003 1. mainly used for melting ingot 5. Used for industry such as automobile,pinning and weaving,electron broadly and so on

2. discontinuous melting with scrap

3. easy control and operation

4. fast melting

3.Packaging & Delivery of Aluminum Ingots AA3003

About 25Kg /Ingot, Packed in wooden case, Net weight 1000Kg/ Case, or as customer's requirements.

- Q: How to make aluminium box into aluminium ingot?

- The problem of aluminum is not high. It can be dissolved directly in a dry pan, but it should not be dissolved directly because the aluminum ingot is pure aluminum, and the aluminum case should have impurities.The smoke isn't too big.

- Q: How many tons of alumina for a ton of aluminum ingot, alumina and electrolytic aluminum what is the difference?

- Alumina is an oxide of aluminum, a compound, an element of aluminum.

- Q: What industries use aluminum ingots?

- The industries that commonly use aluminum ingots include automotive, aerospace, construction, packaging, and electrical industries.

- Q: How do aluminum ingots contribute to the overall aluminum industry?

- The overall aluminum industry heavily relies on aluminum ingots, which serve as the primary raw material for producing various aluminum products. To create ingots, aluminum ore is smelted and the resulting molten metal is poured into molds to solidify. Aluminum ingots offer great versatility as they can be further processed and shaped into different forms like sheets, plates, rods, tubes, and extrusions. These forms find applications in various industries, including automotive, aerospace, construction, packaging, electrical, and consumer goods sectors. Additionally, aluminum ingots provide several advantages that contribute to the growth and sustainability of the aluminum industry. Aluminum is lightweight, corrosion-resistant, and possesses excellent conductivity, making it an ideal choice for numerous applications. Its low density enables energy efficiency in transportation, reducing fuel consumption and emissions in the automotive and aviation sectors. Moreover, aluminum's corrosion resistance ensures longer-lasting products, reducing maintenance and replacement costs. The availability and affordability of aluminum ingots also play a significant role in the aluminum industry. Aluminum is the third most abundant element on Earth's crust and can be easily extracted from bauxite ore. This accessibility, combined with efficient production processes, makes aluminum ingots readily available for manufacturers at competitive prices, stimulating demand and market growth. Furthermore, the recycling potential of aluminum ingots contributes to the industry's sustainability. Aluminum is infinitely recyclable, meaning it can be melted and reused without any loss in quality. Recycling aluminum requires only a fraction of the energy compared to primary production, resulting in significant energy savings and reduced environmental impact. The use of recycled aluminum ingots helps conserve natural resources, reduce waste, and lower carbon emissions. In conclusion, aluminum ingots are indispensable to the overall aluminum industry as they provide the raw material for manufacturing a wide range of aluminum products. Their versatility, lightweight nature, corrosion resistance, and recyclability make them highly valuable for multiple industries. The availability and affordability of aluminum ingots further contribute to the industry's growth and sustainability, while their recycling potential helps conserve resources and reduce environmental impact.

- Q: Can you melt the aluminium ingot?

- Cans and cans and rings are aluminium alloys with different compositions. The tank is made of aluminium alloy coil and punched out each plate first, and then the wafer is deep washed into a tank.

- Q: What are the advantages of using aluminum ingots in the production of renewable energy systems?

- There are several advantages of using aluminum ingots in the production of renewable energy systems. Firstly, aluminum is a lightweight material, making it easier to transport and install in various renewable energy systems such as solar panels and wind turbines. This lightweight characteristic also reduces the load on supporting structures, leading to cost savings in terms of materials and installation. Secondly, aluminum has excellent corrosion resistance properties, which is crucial for renewable energy systems that are often exposed to harsh environmental conditions. This resistance ensures the longevity and durability of the systems, reducing maintenance and replacement costs. Additionally, aluminum is highly recyclable, with the ability to be reused repeatedly without any loss in quality. This recyclability aspect makes aluminum a sustainable choice for renewable energy systems, aligning with the goal of minimizing environmental impact. Furthermore, aluminum has high thermal conductivity, allowing for efficient heat dissipation in renewable energy systems. This property is particularly beneficial in applications like solar panels, where excess heat can reduce efficiency. By effectively dissipating heat, aluminum ensures optimal performance and extends the lifespan of the system. Moreover, aluminum ingots can be easily molded and customized into various shapes and sizes, enabling manufacturers to design renewable energy systems with enhanced efficiency. This flexibility in design helps optimize the system's performance and adapt to different project requirements. Lastly, aluminum is a cost-effective material compared to alternatives like steel or copper. The relatively low cost of aluminum ingots allows for more affordable production of renewable energy systems, making them more accessible to a wider range of consumers. In conclusion, the advantages of using aluminum ingots in the production of renewable energy systems lie in their lightweight nature, corrosion resistance, recyclability, thermal conductivity, design flexibility, and cost-effectiveness. These qualities contribute to the overall efficiency, durability, and affordability of renewable energy systems, making aluminum a preferred material in the industry.

- Q: How to cast aluminum ingots

- Scrap recycling, scrap for the aluminum content is not the same, so I want to return to the pure aluminum, almost impossible, even if feasible, cost is very high, and we generally refers to aluminum ingots, aluminum ingots for remelting, aluminum content of 99.7%, it is a pure substance. Therefore, after the general scrap steel after quenching and tempering, for direct processing Aluminum Alloy or cast aluminum rod.

- Q: What are the challenges in recycling scrap aluminum ingots?

- There are several challenges in recycling scrap aluminum ingots. Firstly, one of the major challenges is the collection and sorting of the scrap aluminum. As aluminum is used in a wide range of products, it can be found in various forms and shapes, making it difficult to collect and sort efficiently. This requires an extensive and organized collection network to ensure the scrap aluminum is properly segregated. Another challenge is the presence of impurities in the scrap aluminum. Impurities such as paint, coatings, and other contaminants need to be removed before the aluminum can be recycled. This requires additional processes and treatments to ensure the quality of the recycled aluminum meets the required standards. Furthermore, the energy-intensive nature of aluminum recycling poses a challenge. Recycling aluminum requires melting the scrap ingots at high temperatures, which requires a significant amount of energy. This can be a challenge in terms of cost and environmental impact, as the energy consumption and emissions associated with the recycling process need to be carefully managed. Additionally, the market demand and fluctuating prices of aluminum can pose challenges in recycling scrap aluminum ingots. The availability of cheaper primary aluminum can sometimes make it more economically viable to produce new aluminum rather than recycling the scrap ingots. This can impact the overall recycling rates and the viability of recycling operations. Lastly, the transportation and logistics involved in recycling scrap aluminum ingots can also be a challenge. As scrap aluminum is often collected from various sources, transporting it to recycling facilities can be logistically complex and costly. Efficient transportation networks need to be established to ensure the smooth flow of scrap aluminum to recycling facilities. Overall, while recycling scrap aluminum ingots offers numerous benefits, there are several challenges that need to be addressed to ensure a successful and sustainable recycling process.

- Q: What is the difference between a aluminium ingot with and without a ticket?

- Beijing's purchase price is the price of aluminum, aluminum ingot + processing fees, billing is generally not a ton of processing fee will be about 400 yuan less, your price is overall, the overall profits can be, I think do not have to manage open ballot problem of aluminum ingots.

- Q: How are aluminum ingots used in the production of aerospace components?

- Aluminum ingots play a crucial role in the production of aerospace components due to their unique properties and characteristics. These ingots are melted down and refined to create high-quality aluminum alloys that are specifically designed to meet the demanding requirements of the aerospace industry. One of the main reasons aluminum is widely used in aerospace manufacturing is its low density. Aluminum is a lightweight material, which helps reduce the overall weight of the aircraft, resulting in improved fuel efficiency and increased payload capacity. This is particularly crucial in the aerospace industry, where every kilogram saved translates into significant cost savings and operational advantages. Another key advantage of aluminum ingots is their excellent strength-to-weight ratio. By alloying aluminum with other elements such as copper, magnesium, or zinc, aerospace engineers can create alloys that possess exceptional strength and structural integrity while maintaining a low weight. These alloys are then used to manufacture various components, such as airframes, wings, fuselage sections, and structural supports, which need to withstand extreme conditions and stresses during flight. Furthermore, aluminum ingots offer exceptional corrosion resistance, making them ideal for aerospace applications. Aircraft are subjected to harsh environments, including exposure to moisture, saltwater, and temperature fluctuations. Aluminum alloys, derived from these ingots, possess a natural oxide layer that provides a protective barrier against corrosion, ensuring the longevity and durability of the aerospace components. Additionally, aluminum ingots can be easily cast, machined, and formed into intricate shapes and designs, allowing for the production of complex aerospace components with high precision. This versatility is essential in the aerospace industry, where intricate and custom parts are required to meet the specific needs and requirements of different aircraft models. In summary, aluminum ingots are essential in the production of aerospace components due to their lightweight nature, excellent strength-to-weight ratio, corrosion resistance, and versatility in manufacturing processes. By utilizing aluminum ingots and their derived alloys, aerospace manufacturers can achieve the perfect balance between performance, durability, and efficiency in their aircraft, contributing to the advancement and safety of the aerospace industry.

1. Manufacturer Overview

| Location | Henan,China |

| Year Established | 1993 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Ingots AA3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Sets Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords