Cryogenic Insulation Paper - Aluminum Foil Laminated for Dewar Containers, LNG, Liquid Nitrogen

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details for Cryogenic Glass Fiber Insulation Paper for Dewar Vessel,LNG

| Feature: | Fire-Proof | Pulp Material: | Wood Pulp | Pulp Style: | Recycled |

| Pulping Type: | Chemical-Mechanical Pulp | Place of Origin: | China (Mainland) | Brand Name: | |

| Model Number: | MP-402 | Weight: | 12±2.0 g/m2 | Thickness: | ≤0.055mm |

| Tensile Strength: | ≥0.031(KN/m) | Harmful Element: | No harmful element | Size: | Customized |

| Color: | White |

Packaging & Delivery

| Packaging Details: | Normal packing with plastic bag and carton box |

| Delivery Detail: | 15 days |

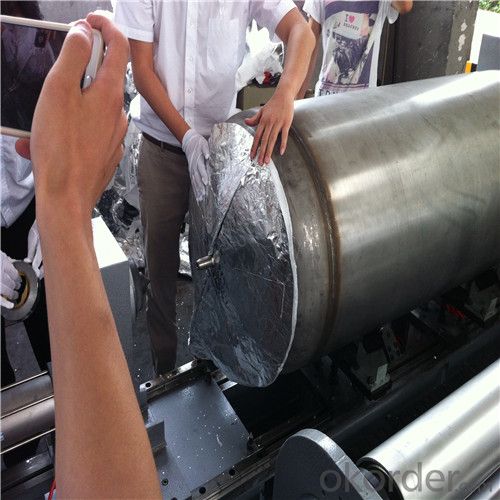

Aluminum Foil Laminated Cryogenic Insulation Paper

Our company manufacture varies kinds of reinforced laminated aluminum foil, we can offer any specification of aluminum foil as customer's requirement.

Welcome to Visit our factory

- Q: I would like to ask how the process of cryogenic treatment

- Biology: fast cooling, can prevent the crystallization of cells in the water, does not destroy the cell organization. In the preservation of sperm, organ preservation, food preservation, preservation of certain life and so onMedical treatment: cryotherapy, treatment of certain skin diseasesSpace: the space environment simulation, satellite ground test station, using liquid helium, create -200 degrees of low temperature.Noise: high sensitivity radar telescope, using liquid helium cooling, receiving device, noise reductionVacuum: the use of cold well technology can get high vacuum

- Q: Can the cryogenic phase control the cooling rate?

- 1, the principle of liquid nitrogen refrigeration: storage of liquid nitrogen in the container through the liquid in the sublimation of heat to take away the heat of the workpiece heat. Liquid nitrogen refrigeration can not be reused after the need to add a new liquid nitrogen, a large range of cooling rate, cooling temperature range of 0-196 degrees C.

- Q: How many changes in the properties of the cryogenic metal?

- 4 milling cutter milling hole surface Phi 12, 48-2NT5 milling cutter milling end 13, 48-2NT6 high speed steel twist drill drilling A3 of 129 2967 high speed steel twist drill drilling 40Cr of 146 3588 high speed steel 8 drill wear 25cr2NiMoV 10 hole 40 hole wear9 high speed steel 10 bit hour HT20-40 1235

- Q: Cryogenic treatment to improve what performance?

- Improve the impact toughness of the workpiece;Improve the internal stress distribution and improve the fatigue strength;Improve the corrosion resistance of the workpiece;

- Q: Ultra low pressure casting mold useful, how to arrange the process? Thank you

- Cryogenic treatment in the connector industry and plastic mold industry has a large number of applications, connectors and plastic products industry production temperature is not high, about 300 degrees! Thus the mold in the production of hot and cold alternating stress is less, after doing a cryogenic treatment, the role of the stability of the size of the more obvious, tube time is longer!

- Q: What is the meaning of vacuum cooling in heat treatment

- Placed for a period of time, known as cryogenic treatment, under normal circumstances are usually treated with liquid nitrogen.

- Q: What is a cryogenic fast line

- Broadly, cryogenic means - the temperature under 100 ℃, in industry can be divided into gas liquefaction technology, chemical industry and material industry of cryogenic treatment.

- Q: What is the meaning of cryogenic technology in the mechanical process, what is the specific practice?

- High speed steel W18Cr4V cryogenic hardness, impact toughness and wear resistance are significantly improved with the use of its manufacturing tool life increased by 2~5 times

- Q: What is the meaning of deep frozen

- In general, the frozen layer of our home refrigerator can only reach -18 degrees, but also slow freezing, slow freezing will have a great impact on food nutrition and flavor.

Send your message to us

Cryogenic Insulation Paper - Aluminum Foil Laminated for Dewar Containers, LNG, Liquid Nitrogen

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords