Cryogenic Insulation Paper for LNG Cylinder

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Aluminum Foil Laminated Cryogenic Insulation Paper

This serial of aluminum foil laminated cryogenic insulation paper is a lamination of multilayer adiabatic cryogenic insulation paper with pure aluminum foil. It saves the customers from self-lamination, thus saving them from material waste both in lamination and application, and also equipment investment.

Image of Aluminum Foil Laminated Cryogenic Insulation Paper

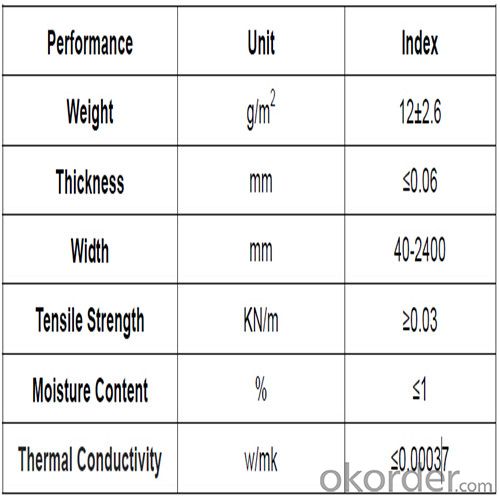

Technical Data of Aluminum Foil Laminated Cryogenic Insulation Paper

Applications of Cryogenic Insulation Paper

Cryogenic Insulation Paper is the top selected insulation materials applicable for cryogenic liquid storage & mobile containers and pipeline systems for liquid oxygen, nitrogen, hydrogen, helium, argon, LNG and etc.

Advantages of Cryogenic Insulation Paper

Flame-retardant

Light

High tensile strength

Low heat conductivity coefficient

Large thermal contact resistance

Low air content under the vacuum and broad operating temperature(-269℃-500℃)

FAQ

Q1: How do you control the products quality?

A1: With strict uality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

- Q: I would like to ask how the process of cryogenic treatment

- Biology: fast cooling, can prevent the crystallization of cells in the water, does not destroy the cell organization. In the preservation of sperm, organ preservation, food preservation, preservation of certain life and so onMedical treatment: cryotherapy, treatment of certain skin diseasesSpace: the space environment simulation, satellite ground test station, using liquid helium, create -200 degrees of low temperature.Noise: high sensitivity radar telescope, using liquid helium cooling, receiving device, noise reductionVacuum: the use of cold well technology can get high vacuum

- Q: Can the cryogenic phase control the cooling rate?

- If it is just a simple container or box, it is difficult to control the temperature. The program can control the temperature of cryogenic equipment, can also control the cooling rate

- Q: How many changes in the properties of the cryogenic metal?

- 10 diamond drill footage of 231.2 meters to 595 meters.11 M6 high speed steel fibers processing aluminum casting parts 1200 40012 high speed steel milling cutter cutting area of copper 350 pieces of 750 pieces13 cutting blade YT798 area A3 51 square meters to 98 square meters14 cutting blade YT798 area ZG15Gr1M01 7 square meters to 12 square meters15 YT330 blade ZG15Gr1M02 for 6 minutes 19.8 minutes16 YT15 blade cutting length 20# low carbon steel 3M 7M17 YT30 blade cutting length 20# low carbon steel 5m 9.7M

- Q: Cryogenic treatment to improve what performance?

- Improve the impact toughness of the workpiece;Improve the internal stress distribution and improve the fatigue strength;Improve the corrosion resistance of the workpiece;

- Q: Ultra low pressure casting mold useful, how to arrange the process? Thank you

- While casting field production high temperature is about 660 degrees, some die casting production Aluminum Alloy temperature of 740 degrees, copper alloy die-casting production temperature even up to about one thousand degrees, the temperature and the ambient temperature, the temperature fluctuation is bigger, hot and cold alternating stress caused by the greater! That is, the stress produced in the production process is very large, even if the cryogenic treatment, the stability of the role of the size of the casting mold and plastic mold is not obvious! As for how you choose, you might as well try!

- Q: What is the meaning of vacuum cooling in heat treatment

- Use a low temperature of 100 degrees below zero

- Q: What is a cryogenic fast line

- Broadly, cryogenic means - the temperature under 100 ℃, in industry can be divided into gas liquefaction technology, chemical industry and material industry of cryogenic treatment.

- Q: What is the meaning of cryogenic technology in the mechanical process, what is the specific practice?

- Copper alloy, hard alloy, plastic, glass and so on to improve the uniformity of low temperature, stable size, reduce deformation, improve service life

- Q: What is the meaning of deep frozen

- Frozen food can make the flavor and nutrient retention is best, and it is said that at -35 deg.c, food oxidation reactions are very slow, that is to say deep freezing over the food nutrition and flavor of fresh food with little difference. In short, deep frozen to fresh.

Send your message to us

Cryogenic Insulation Paper for LNG Cylinder

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords