Aluminum Container Foil Lubricated with 3003 Alloy Tempo H22/H24

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thickness | 0.1mm-8mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm |

Width | 20mm-2500mm |

inner diameter | 76mm / 152mm |

Material | AA1050, AA1060, AA1070, AA1100, AA1235, AA3003, AA3004, AA3005, AA5052, AA5005, AA5754, AA5083, AA8011, AA8079, etc |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38, |

Surface | Mill finish / Coated |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 30-35 days after the receiving L/C or deposit |

2. Application of

(1) Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors, windows,

(2) Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations.

(3).Advertisement: display platforms, signboards, fascia, shop fronts.

3. Feature of

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use.

4. Certificate:

SGS and ROHS (if clients request, paid by client), MTC (plant provided), Certificate of Origin (FORM A, FORM E, CO), Bureau Veritas (if client request, paid by client), CIQS certificate and so on.

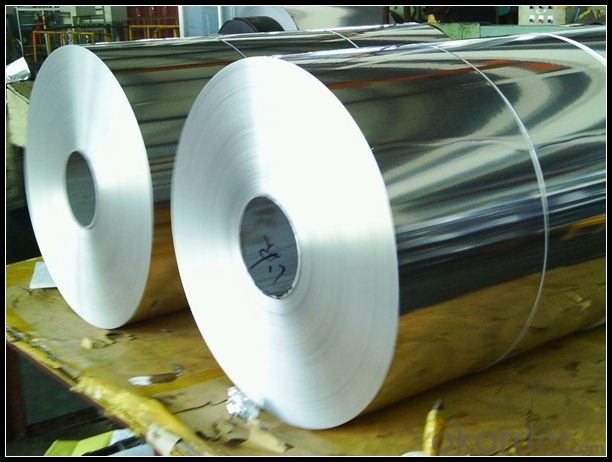

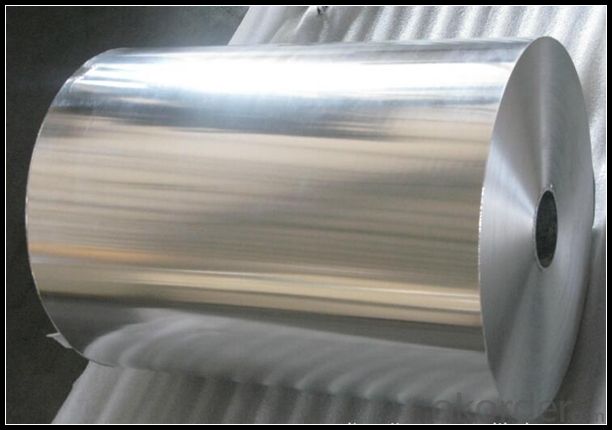

5. Image of

6. Package and shipping of

Eye to wall

Eye to the wall

With wooden pallet (wooden case also available)

7. FAQ

1) What is the delivery time?

Depends on actual order, around 30 to 35 days

2) What is the QC system?

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What causes the explosion of liquid nitrogen container liquid nitrogen tank?

- Liquid nitrogen container design has a special shock proof design, in addition to static storage, transport liquid nitrogen tank can also be transported in the use of filling state. But when the tank body receives a very strong shock and shock, it will cause damage to the insulation layer or other parts of the tank, so that the external environment will directly affect the gasification and cause explosion.

- Q: Considerations for hand held aluminium foil sealing machine

- Should the white glue boards often view the inductive head in front of the color, if there are serious undo charred discoloration, inductive head rib cover to check, whether the induction coil insulation paint carbonization or fall off, if this phenomenon should be replaced or induction coil induction head in a timely manner, so as not to damage the host to continue to use.

- Q: What is aluminum foil?Can it be decomposed by soil?

- Made of aluminum foil in the offset paper with a sodium silicate material mounted, can also be printed. But the foil itself easy oxidation and dark, friction, touch will fade, it is not suitable for long-term preservation of books cover the hot stamping.No. aluminum foil, rubber, plastic packaging bags, they all contain PE, POV, POF, etc. some materials are not decomposed by soilSilent quiet good Ctrl+c autograph is prohibited

- Q: What is the difference between metallized capacitor and metal film capacitor?

- Aluminum electrolytic capacitor common aluminum electrolytic capacitor, it is made of aluminum cylinder, which contains liquid electrolyte, made of a layer of aluminum foil, a layer of insulation coil. Or through the DC voltage treatment, the pole of the film on the formation of an oxide film as a medium. The utility model has the advantages of large capacity, large leakage, poor stability, positive and negative polarity, and is suitable for power supply filtering or low frequency circuits. When using, the positive and negative electrodes do not connect with the reverse.

- Q: What is the material of aluminum foil

- Because of its soft texture and good ductility, it has a silvery luster. If the rolled sheet is made of sodium silicate on the offset paper, the foil can be printed. But the aluminum foil itself is easy to oxidize and the color is dull, friction, touch and so on will fade. Therefore, it is not suitable for the long-term preservation of books, covers and other hot stamping.

- Q: Must there be foil wrapper in the Tea Caddy?

- This really doesn't need it. As long as the container containing tea, the sealing effect is good. The family keeps the tea as long as it keeps dry and doesn't mix. For reference only.

- Q: Is there any harm to the pure milk packing aluminum foil in boiling water?

- There is a polythene film (PE film) inside the aluminum foil package. The temperature of the ordinary boiling water is not enough to dissolve and destroy the PE film, and it will not touch the food. The boiling temperature of the water can not reach the melting point of the PE film, and the milk will not touch the aluminum foil, so the aluminum can not be detected. Aluminum is also relatively stable, it is not particularly lively metal, so simply by boiling it, it does not occur chemical reactions, and then into the food. In other words, in the case of packaging in line with national standards, the packaging of boiled milk will not lead to excessive aluminum.

- Q: How aseptic packaging aluminum foil bags?

- Make aluminum foil bags as food, beverages, pharmaceuticals and pharmaceutical equipment and other materials, one of the best packaging products, especially in its sealing properties, but also make these products have been well protected and promoted. Although plastic bags of ten rich content, in different poses and with different expressions, but the two most basic forms: one is nothing more than open the packing bag use: such as shopping bags, R bags, Ma Jiadai, hand bags, garbage bags, rope bags, food bags and other packaging bag; seal: such as three edges two side sealing, sealing, sealing the ordinary bags, composite bags and cooking bags etc..

- Q: Pan middle foil cake is not able to stick?

- If you are using a cake powder, water and mix thoroughly, add vegetable oil and stir evenly, put aluminum foil paper folded into a square container, will adjust the good batter down on the inside, the aluminum foil containers placed in the oven, the oven on it. Foil foil will be all right.

- Q: Hand held aluminum foil induction sealing machine, how long is the sealing time?

- Hand held aluminum foil sealing machine operation method:The container with aluminum foil sealing machine alignment sensor head center (previously placed induction aluminum foil container cover and tighten the membrane compaction) click on the handle "induction switch", then the original set time countdown to zero, said the work has been completed, and then remove the head of a container under induction a sealing operation.Check the sealing quality, according to different materials, diameter containers, and production efficiency, and properly trim the "time setting button", so that the sealing quality to the best.

Send your message to us

Aluminum Container Foil Lubricated with 3003 Alloy Tempo H22/H24

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords