Aluminium Foil Mylar for Cable Industry from CNBM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 kg

- Supply Capability:

- 400000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

• The WPSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

• Double sided aluminum foil facing vapor barrier, whose structure is aluminum foil/ high strength kraft /fiberglass scrim /aluminum foil and laminated together by special flame retardant adhesive, can be used for roofing, wall insulation of house, warehouse, cold storages, factory and others.

2.Main Features of the Aluminum foil facing:

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

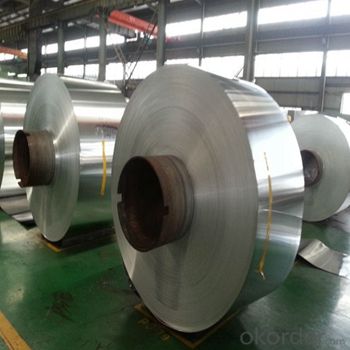

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

(3) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Considerations for hand held aluminium foil sealing machine

- When the induction foil area is too large, press the induction switch, time display immediately to zero without induction or red "overcurrent indicator" flashing with "drop" sound the alarm when the time should be increased by letter and the distance between the sensor head of the post, to the normal work. Can use rubber boards and other things to do the stalls, do not use metal materials instead.

- Q: Can the aluminum foil bowl be heated by microwave oven?

- Because of the coating on the outside of the foil, in any case, the container to be placed in the microwave oven is best to see if there are any text or patterns suitable for the microwave oven

- Q: Is there any harm to the pure milk packing aluminum foil in boiling water?

- As the soft packaging materials, it is in order for us to buy and carry, and is not used as a heating container, so consumers should Hot Milk when drinking or recommend it from this bag onto the glass, or kitchen use high-temperature beaker, containing the aluminum foil packaging milk is absolutely not to heating with microwave oven. In addition, over heating milk also has an impact on nutrition.

- Q: What is the recycling of aluminum foil packs?

- The recycled fiber can be made into recycled paper (such as corrugated cardboard core paper) through the process of paper making. As for the mill can not use aluminum foil and PE parts, the processing method according to the present situation of the equipment or the mills and different, some factories have Cogeneration Equipment, this part can be converted to auxiliary fuel, can assist the incinerator operation, also generated waste residue and sludge is stored to accumulate after a sufficient number, and then sent to landfill landfill or incineration.

- Q: How do you test the resistance value of the aluminum foil of the capacitor?

- At this time, the use of capacitor aluminum foil after the breakdown will automatically repair features, resulting in a repeated breakdown - repair process, and measurement.

- Q: How can I use aluminum foil for microwave oven?

- Other parts of the corner pointed wings, chicken or fish head, tail or cake too easy to cook, cover with aluminum foil wrap can achieve the purpose of cooking evenly.

- Q: Does the disposable aluminum foil lunch box affect your health?

- The aluminum foil lunch box is one of the most healthy food packages now. The foil box has no influence on the body. It can rest assured.

- Q: Does capacitor aluminum foil damage the human body?

- Not too hot, okay, l aluminum element is not good for the body, so try to avoid repeated use as long as possible

- Q: Pan middle foil cake is not able to stick?

- Covered with tinfoil will stick. The foil is coated with a layer of butter on it

- Q: Where is the use of high pressure etching into electronic aluminium foil?

- China's electrolytic aluminum capacitor development is also very fast, according to statistics, in 1997 production of about 15 billion, it is estimated that in the near future may have more than 20 billion. Judging from the development of China's electronic industry, the output of aluminum electrolytic capacitors will be greatly improved in recent years. At present, some parts of China's electrolytic capacitor foil are made in China, and a considerable number of them rely on imports.

Send your message to us

Aluminium Foil Mylar for Cable Industry from CNBM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 kg

- Supply Capability:

- 400000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords