Aluminium Foil Mylar for Cable Industry for All kinds of Fire-Retardant PVC Flexible Ducts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 400000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

• The WPSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

• Double sided aluminum foil facing vapor barrier, whose structure is aluminum foil/ high strength kraft /fiberglass scrim /aluminum foil and laminated together by special flame retardant adhesive, can be used for roofing, wall insulation of house, warehouse, cold storages, factory and others.

2.Main Features of the Aluminum foil facing:

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

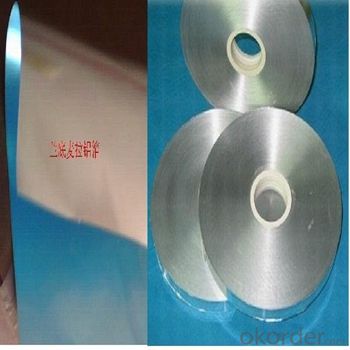

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

- Q: Considerations for hand held aluminium foil sealing machine

- When the induction foil area is too large, press the induction switch, time display immediately to zero without induction or red "overcurrent indicator" flashing with "drop" sound the alarm when the time should be increased by letter and the distance between the sensor head of the post, to the normal work. Can use rubber boards and other things to do the stalls, do not use metal materials instead.

- Q: What is the difference between metallized capacitor and metal film capacitor?

- Metallized film capacitor is a metallized film capacitor that is rolled or laminated with a double-sided metallized polypropylene film and a non - metallized polypropylene film

- Q: Plastic container for food packing container

- Composite film bag: made of different kinds of plastic film or laminated with plastic film and paper and aluminum foil. According to the use and requirements, it can be made of two layers, three or more kinds of composite film bags. Such as polyethylene - polyester, cellophane - polyvinylidene chloride, polyethylene two - polyethylene, paper, polyester - aluminum foil - polyolefin, polyethylene - aluminum foil - paper - polyethylene - polyamide film bags. By hot lamination, coating, adhesive, CO extrusion method for processing and preparing, with special adhesive between layers. One of the typical representatives of composite film bags is a retort pouch for high temperature sterilization. It has excellent isolation, can long-term preservation of food, not deterioration, there are soft canned. The composite material is based on polyester aluminum foil polyolefin. The composite film bag can also be applied to aseptic packaging process, and the full-automatic production line of container forming, food filling and sealing can be successfully realized by using composite material. The recently emerging boxes, bags and barrels are the first aseptic packaging containers developed in the United Kingdom for packaging liquid and mushy foods, such as wines, juices, ketchup, etc.. The packing bag is made of plastic and aluminum foil, and the volume is 5, 20, 200, 220 and 1000 liters. Filling under aseptic conditions, into the corrugated box (5 ~ 200 liters bag) or wooden box (1000 liter bag), called the box into the bag; if the drums (220 liters), it is called barrel bag. Its common feature is convenient storage and transportation.

- Q: Must there be foil wrapper in the Tea Caddy?

- This really doesn't need it. As long as the container containing tea, the sealing effect is good. The family keeps the tea as long as it keeps dry and doesn't mix. For reference only.

- Q: What are the application areas of aluminum foil?

- Electrolytic capacitor with aluminum foil is a kind of work in polar conditions of corrosive materials, structure of aluminum foil have higher requirements, the aluminum foil is divided into three types: the cathode foil thickness is 0.015mm ~ 0.06mm; high pressure foil thickness is 0.065mm ~ 0.1mm, with the requirements of production of high purity aluminum foil; low pressure foil thickness is 0.06mm ~ 0.1mm.Domestic electrolytic capacitor aluminum foil manufacturers are less, mainly market demand is not large, and production technology and advanced countries have a big gap. But the aluminum electrolytic capacitor has the advantages of good performance, low price and wide range of uses, so the market prospect is very good. At present, Japan's annual demand is 45 thousand tons, 6 times that of the Chinese market. With the development of the electronics industry and China as the main industrial production base, the market demand of electrolytic capacitor aluminum foil is broad.

- Q: How aseptic packaging aluminum foil bags?

- Aluminum foil bag is a major cause of the two pollution products after sterilization, disinfection quality of packaging damage to chemical or physical methods of conventional microwave disinfection than conventional heating disinfection required low temperature, a great impact on the quality of the product will not. The use of microwave technology in soy sauce packaging bags to prevent halogen, can prevent soy sauce due to packaging caused by the two pollution problems, and prolong the shelf life of bagged products. In the case of plastic bag sterilization, mainly for sealed aluminum foil bags.

- Q: What are the specifications and uses of common aluminum foil?

- Aseptic packageAlloy status: 1235-O, 8111-O, 8079-OTypical thickness: 0.0063, 0.00635Processing methods: aluminum composite paper, printingEnd use: barrier material with (drinking soda straw) Straw hole rectangular carton packaging, such as Tetra Pak, Combibloc etc..

- Q: Aluminum foil lunch box microwave oven operation method?

- That depends on what kind of aluminum foil lunch box, coated with, for example, rainbow aluminum foil lunch box.Specific use: be sure to open the lid, food should not be too full, placed in the middle of the microwave oven.Hope to adopt, thank you!

- Q: How can I use aluminum foil for microwave oven?

- When microwave oven uses microwave gear, it is not allowed to have any metal substance in the container. Otherwise, a work will start the internal ignition and damage the microwave headIf you want to use the microwave oven barbecue, mini baking sheet, please use the light wave heating (remember). Aluminum foil is used to wrap the barbecue items. (such as Roast Chicken, wrapped in foil to prevent chicken barbecue when oil splash, cause it is difficult to clean the microwave oven, and can prevent the burned chicken)

- Q: Pan middle foil cake is not able to stick?

- Covered with tinfoil will stick. The foil is coated with a layer of butter on it

Send your message to us

Aluminium Foil Mylar for Cable Industry for All kinds of Fire-Retardant PVC Flexible Ducts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 400000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords