Aluminum Composite Foil High Strength Lightweight

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

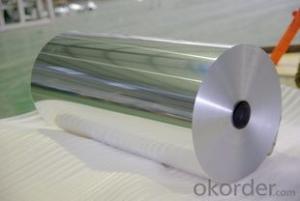

Aluminum Composite Foil is a composite material made by bonding aluminum foil with other materials such as plastic or paper. It is widely used in packaging, construction, electronics, and other fields. By combining the properties of aluminum foil and the characteristics of other materials, aluminum composite foil enhances overall performance.

Main Features:

High Strength: Compared to pure aluminum foil, it has higher strength and toughness.

Lightweight: It has a low density, making it lightweight and easy to transport and install.

Corrosion Resistance: Aluminum has excellent corrosion resistance, and the composite material can further enhance this property.

Good Thermal and Acoustic Insulation: Provides excellent thermal and acoustic insulation, suitable for construction and home decoration.

Easy to Process: It can be processed through cutting, bending, stamping, and other methods to meet various application needs.

Advantages:

Versatility: Can combine the advantages of multiple materials, such as the moisture resistance of aluminum, the sealing properties of plastic, and the printability of paper, to meet various packaging needs.

Cost-Effective: Compared to pure aluminum foil, aluminum composite foil is more cost-effective.

Environmentally Friendly: Aluminum composite foil can be recycled, reducing environmental pollution and resource waste.

Aesthetic Appeal: The surface of aluminum composite foil can be decorated through various treatments such as printing, embossing, and coating, enhancing the product's appearance.

Wide Application: Widely used in food, pharmaceuticals, construction, electronics, and other fields, with broad market prospects.

Applications:

Food Packaging: Extensively used in food packaging, such as chocolate wrappers, beverage pouches, and pharmaceutical packaging, providing excellent sealing and preservation.

Construction Materials: Used in building exterior wall decoration, roof insulation materials, etc., offering thermal insulation.

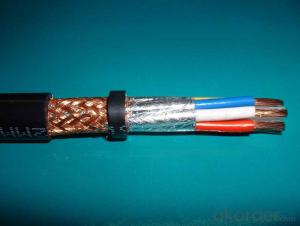

Electronic Products: Used in electronic products as shielding materials and heat dissipation materials, providing good electromagnetic shielding and heat dissipation.

Specification:

PROPERTIES | UNIT | VALUE | TEST METHOD |

| Basic weight | gsm | 33.5 | ASTM D646 |

Thickness | mic | 23.2 | ASTM D646 |

Tensile strength | N/15mm | 13.5 | ASTM D882 |

| Delaminating Values | N/15mm | 1.5 | ASTM D904 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -40°C-130°C | No Delamination | ASTM C1263 |

Water vapor permanence | ng/N.s | 1.15 | ASTM C1263 |

Images:

FAQ:

We have organized several common questions for our clients, may help you sincerely:

1) Where you used this foil?

Aluminum Mylar foil Shielding Foil is used for cable shield, candy wrap for the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

2)How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3)How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How do you handle the cursor distance of the foil composite film?

- Suggested use Baidu Search eighth towers for more soft packing people view

- Q: How can I clean the aluminum foil products when they are punched out?

- There are many kinds of drawing oils, and there are usually special cleaning agents. You can specifically ask your drawing oil supplier, according to the oil purchase.

- Q: What is the material of aluminium foil yogurt cover?

- The aluminum foil backing paper and aluminum foil paper bonding paper. Soft, easy to change, such as paper, and does not rebound after deformation

- Q: Do you want the foil removed from the outlet of the central air conditioner?

- It can not be removed. It is a layer of protective material wrapped outside the heat insulation material, which acts as heat insulation.

- Q: What is a composite aluminum foil molded poly vinyl foam board, and what is a composite aluminum foil extrusion poly vinyl vinyl insulation board, the two how to distinguish?Please try to be more specific

- 5, flame retardant properties of EPSXPS can reach B1 B26, the price of EPS is lower than XPSConclusion, if used in air conditioning, air duct and so on, XPS is superior in performance analysis,

- Q: Car sunshade and black aluminum foil which is good, and the aluminum foil is white or cartoon, mainly considering the shading effect

- The car shade is made of aluminum foil. The best color is white, the effect is good, if you like the cartoon, choose light color.Aluminum foil in general, general "light plate" type and pattern type, size is generally 60*130cm, suitable for most small cars. The aluminum foil heat shield with suction cup is easy to use. After expansion, it can be sucked in front windshield or inside rear window by suction cup.

- Q: Some drugs are wrapped on an aluminum foil board. What's the function of an empty plastic cover?

- Generally fragile, the outer PET transparent wrap is designed primarily to effectively isolate airborne bacteria, dust, and moisture

- Q: How do you microwave the chicken wings with aluminum foil?

- The main marinade is salt, soy sauce, chopped green onion, sugar, pepper, these are indispensable. Especially to put enough sugar and pepper sauce, of course, have flooded after more than good. It can be a little longer. It's flooded in the first afternoon, then refrigerated in the fridge and baked in second days. Bake about 350 to 400 degrees, about 40 minutes. After a night like chicken wings soaked exceptionally tasty, baking time can smell the aroma in the house. It would be better to turn over.

- Q: What are the areas in which aluminum foil is applied?

- Preparation of polyaluminium chloride from waste aluminium foilPolyaluminium chloride is a common inorganic polymer flocculant. The wide range of raw materials for the production of polymeric aluminum chloride sets the foundation for its development. Especially, the production process is various, which provides convenience for the development of polyaluminium chloride.

- Q: How to wrap foil briquettes fire chimney?

- Two, there is no need to do thermal protection like air conditioning pipes;

Send your message to us

Aluminum Composite Foil High Strength Lightweight

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords