Aluminum Composite Foil for Cable Foil and Package

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Composite Foil for Cable Foil and Package

1.Structure of Aluminum Mylar foil Shielding Foil Description:

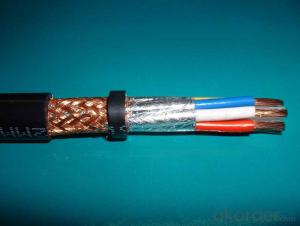

Electrical cable is used to transfer electricity, information and the realization of electromagnetic energy transformation. The electrical cable in a broad term mainly indicates to cable and in a narrow term indicate insulation material. Its definition is the aggregation of different parts below: one or more insulation cores, the wrapping layers of the cores, the general protective layers and the outer protective layers. Cables also include additive conductor without insulator.

2.Main Features of the Aluminum Mylar foil Shielding Foil:

Aluminum Mylar foil Shielding Foil is applicable to the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

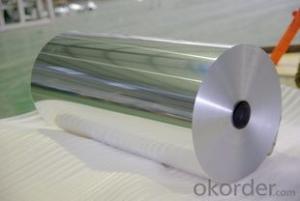

1.Thickness: min 6.5mic; width: 300-1000mm.

2. According to GB/T 3198-2010.

3.Usages: cable shield, candy wrap

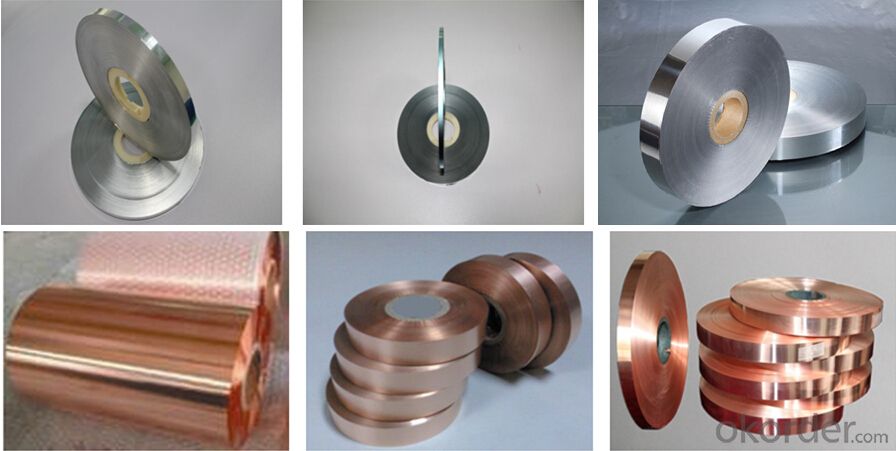

3. Aluminum Mylar foil Shielding Foil Images

4. Aluminum Mylar foil Shielding Foil Specification

AL-PET laminated foil

Description: Apply for overall or individual twisted pair shield for electronic cable and local network cables, protect from external electromagnetic interference. Features option of LUBRITAPE apply to decrease 50% friction of aluminum surface.

Construction: Aluminum foil, Polyester film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

FP007012 | 22±3 | 7 | 3 | 12 | 38.8±5% |

FP010012 | 25±3 | 10 | 3 | 12 | 46.9±5% |

FP020020 | 43±3 | 20 | 3 | 20 | 83.8±5% |

FP025012 | 40±3 | 25 | 3 | 12 | 87.6±5% |

Special specifications are also available, according to customer’s order. | |||||

AL-PET-AL laminated foil

Description: resilient shielding in cable assembling and provide the enhanced shielding required in harsh environments.

Construction: Aluminum foil +Polyester film+ Aluminum foil

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | WEIGHT |

DFP007015 | 35±3 | 7 | 3 | 15 | 3 | 7 | 65±5% |

DFP009020 | 39±4 | 9 | 3 | 15 | 3 | 9 | 76±5% |

DFP015025 | 61±5 | 15 | 3 | 25 | 3 | 15 | 115±5% |

DFP025025 | 80±5 | 25 | 3 | 25 | 3 | 25 | 175±5% |

Special specifications are also available, according to customer’s order. | |||||||

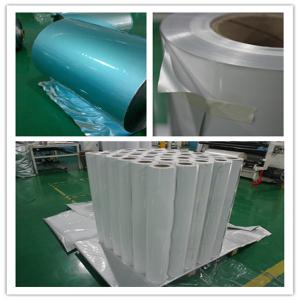

Bonded AL-PET laminated foil

Description: A laminated aluminum-polyester-aluminum tape is fully bonded to the foam dielectric to provide 100% coverage, longitudinally applied over the polyethylene core and the tape minimizes signal leakage.

Construction: Aluminum foil + Polyester film + Aluminum foil + EMAA film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | GLUE | EMAA | WEIGHT |

DFPH009012 | 65±5 | 9 | 3 | 12 | 3 | 9 | 3 | 25 | 98±5% |

DFPH009020 | 72±5 | 9 | 3 | 20 | 3 | 9 | 3 | 25 | 108±5% |

DFPH009025 | 75±5 | 9 | 3 | 25 | 3 | 9 | 3 | 25 | 114±5% |

DFPH010025 | 84±5 | 10 | 3 | 25 | 3 | 10 | 3 | 25 | 126±5% |

Special specifications are also available, according to customer’s order. | |||||||||

Copper polyester foil

Description: Copper foil, copper lamination foil typically use as shielding for low/medium voltage cable and radio frequency coaxial cable. The rolled annealing copper foil is flexible to wrap cable core, also it has the excellent physical properties, Polyester film provides electrical insulation and high mechanical properties.

Construction: Copper foil + Polyester film

CODE | TOTAL THICKNESS | CU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

CP018012 | 33±3 | 18 | 3 | 12 | 175±10% |

CP007020 | 46±3 | 18 | 3 | 25 | 195±10% |

CP015012 | 30±3 | 15 | 3 | 12 | 160±10% |

Special specifications are also available, according to customer’s order. | |||||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this foil?

Aluminum Mylar foil Shielding Foil is used for cable shield, candy wrap for the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Can aluminum foil be used in a microwave oven?

- Aluminum foil in microwave function should not be used, because microwave is not metal material, easy to fire

- Q: Aluminum foil waterproof material, how much does it cost for a square?

- Our 16 piece is mainly insulated and waterproof. Aluminized about 5-8 pieces

- Q: Can foil be insulated?Indeed, the foil is reflective of the sun's rays

- To be exact, the foil reflects the sun's rays and turns the radiation to other places instead of heat insulation, but it acts as heat insulation. The brighter the foil, the stronger the reflectivity.

- Q: Battery why aluminum foil as anode, copper foil as negative electrode?

- There are many reasons for that.First of all, Al will form lithium aluminum alloy at negative polar potential, that is to say, Al will insert lithium when it is negative. Similarly, Cu in the positive electrode, high potential will be oxidized. Therefore, the selection of these two metals mainly takes into account their stability at different potentials.

- Q: What size is the aluminum foil bag?What are the commonly used sizes?

- General market of an aluminum foil bag: LED lights, aluminum foil bags, specifications for 0.14*21.5*23.5CMYou can customize what size you want, and you can also print the bag in multi colour, which perfectly reflects the brand effect of the product. You deserve it.

- Q: Which bags are better, such as shield bag, aluminium bag and aluminum foil bag?

- Shielding bag, aluminium plated bag, aluminium foil bag. In terms of price, the most expensive foil bags, followed by aluminum bags, and finally shielding bags, mainly because of the different components of aluminum foil content.

- Q: Black shading and shading of the aluminum foil machine what is the difference

- At the same time, a knitting fabric is formed, which is called warp knitting. The fabric is called warp knitting fabric. The warp knitting machine is called warp knitting machine

- Q: How to calculate the aluminum foil material?How can we calculate the number of meters with weight, length and thickness?

- The weight depends on the length, width, density, thickness of the foil. If there is a composite film, the density of the plastic film and the density of the glue will also need to be known

- Q: In case a bright paper is aluminum foil or foil with what method can distinguish and what contain aluminum foil

- A layer of bright in cigarette paper are not foil foil, the foil is a call before

- Q: How to wrap foil briquettes fire chimney?

- Three is the main reason for chimney fire is the smoke fouling of organic matter can be burned. So I don't know what you're going to do with the foil wrapping the chimney

Send your message to us

Aluminum Composite Foil for Cable Foil and Package

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords