Aluminum Channel for LED Light Strips with SGS and RoHS Certificate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

One of the best known properties of aluminium is that it is light, with a density one third that of steel, 2.700 kg/m3. The low density of aluminium accounts for it being lightweight but this does not affect its strength.

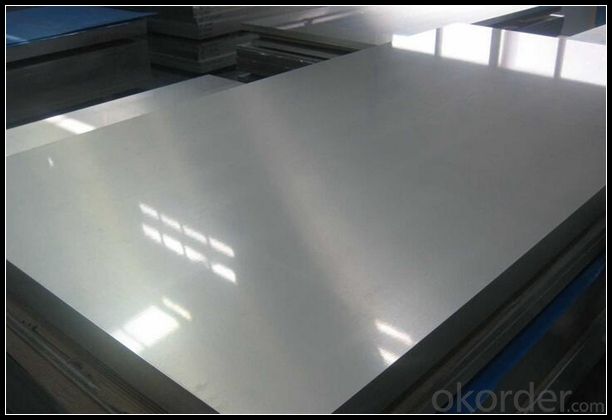

4. Image of Aluminum

5. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

6. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: What are the various kinds of flooring options available that utilize aluminum strips in their construction?

- <p>Aluminum strip flooring comes in several types, each with unique characteristics. One common type is aluminum strip laminate flooring, which combines aluminum strips with a laminate surface for durability and style. Another is aluminum strip interlocking flooring, known for its easy installation and resistance to moisture. There's also aluminum strip parquet flooring, which mimics the look of wood parquet but with the benefits of aluminum. Lastly, aluminum strip modular flooring is popular for its versatility and ability to be easily replaced or reconfigured. Each type offers different benefits, such as resistance to wear, moisture, and heat, making them suitable for various environments, from residential to commercial settings.</p>

- Q: Is it possible to use aluminum strips as a material for wall cladding?

- <p>Yes, aluminum strips can be used for wall cladding. They are lightweight, durable, and resistant to corrosion, making them suitable for both interior and exterior applications. Aluminum strips are also easy to install and maintain, and they can be painted or finished in various ways to match different architectural styles. However, it's important to ensure that the aluminum is of high quality and that the installation is done correctly to achieve a secure and aesthetically pleasing result.</p>

- Q: Is it possible to utilize aluminum strips in constructing a rainscreen wall system?

- <p>Yes, aluminum strips can be used to create a rainscreen wall system. Aluminum is a popular choice due to its durability, resistance to corrosion, and low maintenance requirements. It allows for proper ventilation and drainage behind the cladding, which helps prevent moisture damage and thermal stress. When designing a rainscreen system with aluminum strips, ensure that the installation follows building codes and standards, and that the strips are properly spaced and sealed to maintain the system's effectiveness.</p>

- Q: What types of aluminum strip are best suited for outdoor or exterior applications?

- <p>Yes, certain types of aluminum strip are particularly suitable for exterior applications. These include aluminum strips with high corrosion resistance, such as those with a 3003 or 5052 alloy composition. They are often coated with a protective layer, such as anodizing or a paint finish, to enhance their durability against weather conditions. Additionally, aluminum strips with a thicker gauge are more resistant to denting and wear, making them ideal for exterior use. It's also important to consider the specific environmental conditions of the application, such as exposure to saltwater or extreme temperatures, to select the most appropriate aluminum strip for the job.</p>

- Q: How does the excavator aluminum belt turn in place?

- Because of the difficult turning of the track, the excavator's track turn in situ makes the excavator turn.

- Q: This question asks about the environmental impact of aluminum strips, which are thin pieces of aluminum metal.

- <p>Aluminum strips can have both positive and negative effects on the environment. On the positive side, aluminum is highly recyclable, and using recycled aluminum reduces the need for mining new bauxite, thus conserving natural resources and reducing the environmental impact of mining. However, the production of aluminum, especially from raw materials, is energy-intensive and contributes to greenhouse gas emissions. Additionally, improper disposal of aluminum can lead to pollution, as it does not degrade naturally and can accumulate in landfills. The environmental impact can be mitigated by promoting recycling and responsible disposal practices, as well as by using aluminum more efficiently in products to extend their lifespan and reduce waste.</p>

- Q: Is it possible to utilize aluminum strips as a material for insulating interior walls?

- <p>Aluminum strips are not typically used for interior wall insulation. Insulation materials are designed to provide thermal resistance, and aluminum is a good conductor of heat, which makes it unsuitable for insulation purposes. Common insulation materials include fiberglass, mineral wool, and polyurethane foam, which are effective at reducing heat transfer. Aluminum strips might be used in construction for other purposes, such as reinforcement or as a vapor barrier, but not for insulation.</p>

- Q: This question asks for an explanation of the corrosion protection mechanism provided by aluminum strips.

- <p>Aluminum strips protect against corrosion through a process known as sacrificial anode cathodic protection. When aluminum is exposed to an electrolyte (like soil or water), it naturally forms a thin, protective oxide layer on its surface. This layer prevents further oxidation. In a galvanic cell, aluminum acts as the anode and corrodes preferentially, sacrificially protecting the cathode, which is usually a more noble metal like steel. The aluminum strip corrodes instead of the steel, thus preventing the steel from corroding. This method is effective because aluminum is more reactive than steel, and it corrodes at a slower rate once the initial protective layer is formed, making it a sustainable protection method.</p>

- Q: What kind of mask is good for welding aluminum strips?

- The welding aluminum strip will produce certain peculiar smell and aluminum chip. Can solve this problem at the same time, activated carbon mask can solve, activated carbon can absorb some peculiar smell, at the same time can come dust.

- Q: Which brand of aluminium band for dry transformer?

- The domestic brand is 1060, and the state is soft. Suitable for winding.

Send your message to us

Aluminum Channel for LED Light Strips with SGS and RoHS Certificate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords