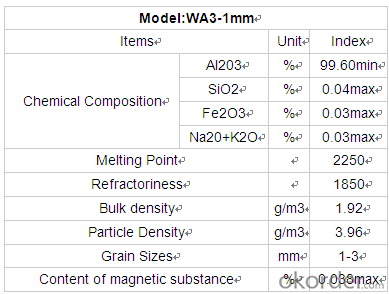

Alumina Oxide Al2O3 - Raw Materials for Refractory - Industrial Grade Good Quality Competitive Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Industrial grade Good quality alumina oxide al2o3

Specification:

High purity AL2O3 Aluminum Oxide/ Aluminum powder

Manufacturer

Superfine

Application of AL2O3

Aluminum Oxide for aluminum smelting, glass, ceramic industry etc.

Aluminum Oxide for refractory, coating, abrasive application.

Aluminum Oxide for electric basal plate, desiccating agent, chemical and pharmacy industry etc.

aluminum oxide property:

Soluble in water white solid. Odourless. Tasteless. Qualitative very hard. Easy absorption of moisture and not ChaoXie. Both sexes oxide, soluble in inorganic acid and alkaline solution, almost insoluble in water and the polar organic solvents. The relative density (d204) 4.0. Melting point about 2000 °C.

The physical and chemical analysis:

Main standard:

Alumina(industry grade) made by slkali-lime sintered,It is white powdered crystal with low assay of Ti, Mn, Zn, Cu, V, Zr, Cr, Li, Pb, B, P, etc.It is used in the production of fused salt eletrorefining aluminium, corundum eramics, refractories and other alumina chemical products.

Product Pictures:

If you’ve any enquiry please don’t hesitate to contact us!

- Q: How long can gypsum board endure fire?

- General gypsum plaster board with a thickness of less than 12mm has a fire endurance which is less than half an hour. Scheme One of gypsum board partition system by using 75# series of lightgage steel joist: separation distance of keels keep 600mm in vertical direction. The thickness is greater than 0.5mm; gypsum board: it shoule be the board of double-sided and single-layer with the thickness of 12mm. Fire-resistant gypsum plaster board's fire-resistance limit: 1 hour. Sound insulation index: over 35 rwdb.

- Q: How long does it take for refractory cement to solidify?

- 1. First you should be aware of the concepts of condensation and condesation time. Refractory cement belongs unshaped refractories, which when added water or liquid binding agent to mix, the agitation material will gradually lose thixotropy or plasticity and become in a state of solidification, thus is solidified. The time needed to finish the process is called solidification time. The whole process is divided into initial and final set. When beginning to lose plasticity called the initial setting, when called plasticity completely lost the final setting. 2. For refractory cement, the solidification time depends on the matching of the material and the parts and using methods. Under normal circumstances, in order to meet the requirements of time of construction, the initial set time should be no shorter than 40min, and the final set time should be no longer than 8H 3. There are also some exceptions. When refractory cement is used for spraying and injection operation together with other refractory castable, the set time is required as short as possible, sometimes flash set is required to prevent the occurrence of peeling or collapse of the spraying layer.

- Q: Urgently!! Refractory problems, online, etc.

- The service life of most refractory materials is a pair of contradictory effects. As a result, one aspect of the contradiction is porosity, and the other is volume density. The larger the volume density is, the smaller the porosity is and the more erosion resistant, but the thermal shock effect is very poor. The bigger the porosity is, the smaller the volume density is, the better the thermal shock effect is, but it is not resistant to erosion. More professionally, two curves should be made to find the intersection of the curves to adjust the recipe and production process

- Q: What is fireproofing material? Are fireproof materials the same thing with thermal insulation materials and refractories?

- The refractory material is capable of withstanding high temperature burning, while fireproofing material is to prevent burning. They are different from each other

- Q: Who knows how many kinds of fireproof insulation materials are there in the market?

- Portland cement, insulation stone, calcium powder and platycodon grandiflorum are the main raw materials of inorganic active insulation materials. Advanced manufacturing techniques and chemical Technologies have been used to conduct many tests, thus the close-celled inorganic active insulation materials are successfully developed. Products have advantages of fire-resistance, small deformation coefficient, aging-resistance, stable performance, environmentally-friendly, and good compatibility with rendering coating and subtractive wall, security, stability, and also have a life as long as the building itself. Good fireproofness: The materials of fireproof insulation board are inorganic (cement) which has A1-level fire-resistance, are non-combustible materials, and good at resisting fire. I hope my answer can help you.

- Q: What are the common refractory insulation cotton material?

- High aluminum, clay brick, aluminum silicate fiber module and so on, inorganic types are glass wool, rock wool, foam glass etc.. Organic: the best one is phenolic foam, compround phenolic foam cement layer is a-level. Aerated concrete and other refractory thermal insulation material mainly refers to the inorganic thermal insulation materials and compround thermal insulation material, expanded perlite, foam clay It is applicable for buildings that have high requirement for fire proof level, foamed concrete, volcanic ash glass.

- Q: How to choose construction external wall thermal insulation and fireproofing materials?

- The width of fireproof partition shuld be greater than 30CM, and the thickness should be the same as total thickness of thermal insulation materials. Fire barrier zone thermal insulation board and base wall should be stuck in whole area. Fire Barrier zone thermal insulation board should be stuck with the assistance of anchor bolt which must press the mesh of the bottom layer. Fire Barrier zone should be set above the door and window, with a distance of less than 50cm between the lower edge of fire barrier zone and the upper edge of window.

- Q: What kind of refractory decorative board has good quality?

- Baby Rabbit has excellent refractory decorative board. It once won the Chinese famous brand, and was awarded iconic brand in plywood industry and the most influential integrated service providers of indoor decoration materials . Fireproof?panel is made from body paper(titanium coated paper, kraft paper) in high temperature and pressure through impregnation technology of melamine and phenolic resin. Refractory door slab is made by sticking fireproof?panel on base materials such as density board or chipboard.

- Q: What is the the best matching ratio of refractory cement?

- The ratio of cement and sand is about 30 per cent. Properties and Applications of refractory mortar: 1, Good plasticity and easy construction; 2, High bonding strength and strong corrosion resistance; 3, Relatively high refractoriness up to 1650 ℃ ± 50 ℃; 4, Good slag corrosion resistance; 5, Good thermal peeling. Refractory mortar is mainly used in coke ovens, glass furnaces, hot blast furnace and other industrial furnaces. Applied industry: Metallurgy, building materials, machinery, petrochemicals, glass, boiler, electric power, steel, cement, etc. And refractory cement is also known as aluminate cement. Aluminate cement takes bauxite and limestone as raw materials, alumina content of about 50% as the clinker. And it is a hydraulic cementing material made by grinding. Refractory cement is also known as aluminate cement. Aluminate cement is often yellow or brown or gray. The main mineral of aluminate cement is mono calcium aluminate (CaO · Al2O3, abbreviated CA) and other aluminates, and a small amount of dicalcium silicate (2CaO · SiO2), etc. It is a special cement.

- Q: What kind of materials are needed to make refractory bricks?

- Refractory materials generally refer to inorganic non-metallic materials with fire resistance above 1580℃. It plays an important role in metallurgy, nonferrous metals, chemical engineering, ceramics, and industrial production. Different industry needs different materials. You can turn to the knowledgeable internet.

Send your message to us

Alumina Oxide Al2O3 - Raw Materials for Refractory - Industrial Grade Good Quality Competitive Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords