Alu Alu Foil alu45-65micron for Blister Packaging

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specification

WIDTH | THICKNESS ( MICRON) | TOTAL THICKNESS | CORE SIZE | ROLL LENGTH | MOQ | ||||||||

OPA | AL | PVC | |||||||||||

≤600mm | 25 | 45-65 | 60 | 130-165um | 76mm | 240-280m | 0.2MT | ||||||

PACKING | Inner packing: each roll to be wrapped with sack polyethylene. Outer packing:carton packing,wrap by film then pallet packing. | ||||||||||||

Function | A high obstruction, A high photophobic, good oxygen resistance, moisture proof, forming, Improve packaging grades and to extend product shelf life |

Character 1 | Construct agglutination is strong not easy to layered or open |

Character 2 | Take some content of tablets, NO impact on the same other well-packed medicinal parts |

Character 3 | Tested by a 30-um pinhole, completely avoid minor damages that can not tested by eyes |

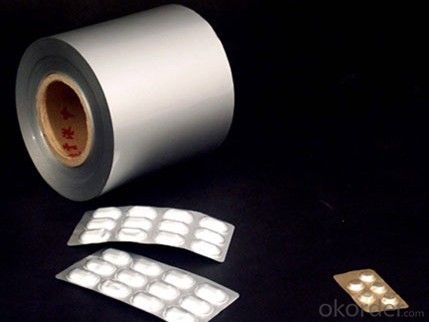

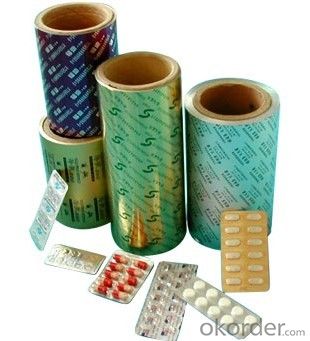

Application | Gels, tablets, capsules, injection, the outer packaging of disposable medical devices,the inside packaging of comestic |

Remark | The primary selection for high grade medicine under extreme high or low temperature. |

2. Application:

Cold Forming Blister Aluminum Foils can resistance to moisture, gasses and UV Ray, provide the utmost protection for medical products with strict protection requirements.

3. Advantages:

It is commonly used for medicines, medical equipments and diagnostic products packing. It could be used base on the product packing sizes, the stretch of AL/Plastic composite measure, and the performance of cold formable to handle any forming blister.

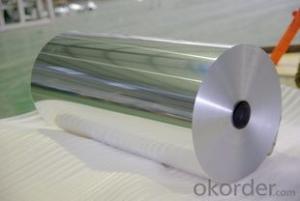

4. Pictures:

5.FAQ:

How about delivery time?

40~50 days.

How about MOQ?

One ton per size.

What's the payment term ?

100% irrevocable LC at sight or 30% / 20% advance balance TT against BL copy.

- Q: When the wire is made, it needs a layer of foil inside, and the outside is insulated. Why is that?

- Insulation is done outside to protect or leak electricity.The cable foil is coated with plastic film on one or both sides with the tightness and shielding of aluminum foil

- Q: When installing gas water heater in our house, the installation master will connect the aluminum foil smoke pipe directly to the smoke exhaust port of the machine, but the Internet says it can not be installed like this. What's wrong with this?

- Installation violations in a regionCase 1:1, illegal use of aluminum foil smoke pipe and machine smoke outlet direct connection;2, the connection does not use aluminum foil sealing tape, smoke is easy to leak, once the smoke pipe loose, the consequences will be unimaginable.

- Q: How many degrees of aluminum foil can burn?

- You can use ordinary lighter lit, but not spontaneous combustion, left his flame out

- Q: Excuse me, the foil can be used in the microwave oven?

- 3, the use of paper towels and cloth towels. A piece of chicken slices baked with bread or biscuit or bread crumbs and served with a paper napkin under the food to keep the food surface dry and crisp. When making steamed bread or cakes, it can be sealed or wrapped with wet gauze or paper towel to prevent moisture from evaporating.4, halfway to stir soups, steak or steak turn over, or overlap the more serious food reset, help to enhance the cooking effect.5, at the end of the heating period, the use of food for a period of time or for some food additives with some seasoning (such as cooking poultry meat, pour the emulsified oil or sauce on the face, then sprinkle some pepper powder, bread crumbs, etc.) can achieve satisfactory effect of heating can not do.

- Q: I heard that using aluminum foil and salt to add water can make the silver ring bright. Who told me what aluminum foil is and where can I buy it?

- Aluminum foil paper is made from aluminum foil backing paper and aluminum foil paper bonding paper. Soft, easy to change, such as paper, and does not rebound after deformation. The utility model can be characterized in that the utility model has the advantages of ensuring shading, no falling, no light transmission, no pollution, and low price. Aluminum foil paper as an industrial raw and auxiliary materials, products are mainly used in packaging, protection, daily necessities, buildings and so on. The initial development of Hebei Langfang Dacheng is a common type of application in construction, and is mostly used in industrial buildings. It should conform to the application type and basic requirements of auxiliary building materials. Production began in 1932 and the test was successful. Aluminum foil is a new type of industrial material. Will replace more single material, widely used in a variety of flexible packaging. With economic development, China will become the world's most important packaging demand market. Aluminum foil packaging development prospects are very broad.

- Q: The foil can work in 430 degree heat?

- The melting point of aluminium is 660.4 degrees centigrade and the boiling point is 2467. The foil can resist high temperature, but it will be oxidized

- Q: With foil and foil barbecue which is better?

- Because many seasonings will add some juice, citric acid or acetic acid, but whether it is vinegar (vinegar or vinegar), are acidic substances, if contact with tinfoil or aluminum foil under high temperature metal release, so that the metal content of food rose. Lin Jieliang believes that the single use of tin foil or aluminum foil, separated by high temperature charcoal, can prevent food from burning caused by carcinogens, is more healthy food, but do not recommend adding seasonings containing acidic substances

- Q: The aluminum foil I bought reads, "microwave ovens, be sure to refer to the microwave oven instructions."".My microwave oven has barbecue. With foil wrapped in meat into the microwave oven, how should operate? Is that all right? With a microwave or a light wave?

- The use of aluminium foil:Other parts of the corner pointed wings, chicken or fish head, tail or cake too easy to cook, cover with aluminum foil wrap can achieve the purpose of cooking evenly.

- Q: Black shading and shading of the aluminum foil machine what is the difference

- At the same time, a knitting fabric is formed, which is called warp knitting. The fabric is called warp knitting fabric. The warp knitting machine is called warp knitting machine

- Q: Why can copper foil and aluminum foil shield electromagnetic signals?

- Therefore, they usually back conductive adhesive, otherwise shielding effectiveness is very poor, under normal circumstances, with conductive adhesive copper foil / aluminum foil can reach more than 90dB, with flying conductive adhesive only about 40dB

Send your message to us

Alu Alu Foil alu45-65micron for Blister Packaging

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords