ALLOY HOT ROLLED ROUND BAR JIS/GB/DIN STANDAR

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

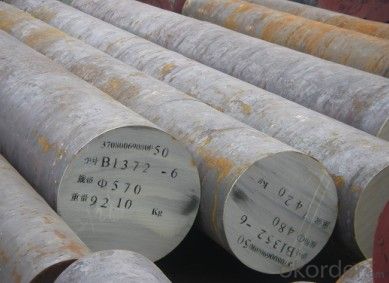

Specifications of Bearing Steel Round Bar

Grade | AISI 52100, ASTM E52100, DIN 1.3505,JIS SUJ2, GCr15 |

Dimensions | Diameter: 30-60mm Length: 2000-13000mm or as required |

Shape | Round Bar |

Type | Alloy Steel Bar |

Delivery Condition | Black Surface |

Material | Bearing Steel |

Technique | Hot Rolled |

Usage and Applications of Bearing Steel Round Bar

Bearing steels are used for ball and roller bearing applications and are comprised of low carbon steels and high carbon through harden able steel.

First the famous 1C-1.5Cr steel from which the majority of bearings are made. Its structure is apparently well-understood and the focus is on purity in order to avoid inclusions which initiate fatigue during rolling contact. Then there is the M50 steel and its variants, from which bearings which serve at slightly higher temperatures in aeroengines are manufactured, based on secondary-hardened martensite.

Tapered roller bearing are generally used to support combined load mainly consisting of radial load. Their cups are separable for easy assembling ,During mounting and using, radial clearance and axial clearance can be adjusted and preloaded mounting can be made.

Packaging & Delivery of Bearing Steel Round Bar

Packaging Detail: ASTM 52100 Steel in seaworthy packing or on customer request; Packed in bundles with standard export sea-worthy package or as customer require

Delivery Detail: 45 days after confirmed

Trade terms: FOB, CFR, CIF ou as customer's required

MOQ: 25 tons or at customer's demands. If the quantity is good, the price will be better.

Processing of Bearing Steel Round Bar

The processing of Bearing Steel Round Bar is hot rolled (strictly control sulphur, phosphorus and non-metallic inclusions content and distribution)

Chemical Composition of Bearing Steel Round Bar

C | Si | Mn | Cr | Ni | Cu |

Equal or less than | |||||

0.95-1.05 | 0.15-0.35 | 0.25-0.45 | Cr:1.40-1.65 | 0.30 | 0.25 |

All products' chemical composition and specification can be design according to customers' requirement.

Note of Bearing Steel Round Bar

1. According to national standard (GB) for our products, if not, supply according to national standards (GB) or agreement.

2. We can not only provide electric furnace +LF+VD and electros lag re-melting (ESR) steel forging materials, but also forging products of piece, bar, etc.

3. Our company is equipped with roll equipment and can provide our customers with roll billets or finished.

4. Please send us your detailed specifications when inquire. We will reply to you ASAP.

5. Certificate of quality is issued in English, in addition the normal terms, production process, the mechanical property (yield strength, tensile strength, elongation and hardness. forged ratio, UT test result, Grain size, heat treatment methods and the sample of is shown on the certificate of quality.

- Q: How do you cut steel round bars?

- To cut steel round bars, one can utilize various methods based on specific requirements and available tools. Here are a few commonly employed techniques: 1. Abrasive Cutting: By using a handheld angle grinder or chop saw equipped with an abrasive cutting wheel or disc, a groove is created on the surface of the round bar. Applying pressure and rotating the bar gradually allows the cutting wheel to slice through the steel. 2. Cold Saw: This specialized machine operates with a circular blade at a low speed, minimizing heat generation. The round bar is firmly clamped, and the cold saw's blade is lowered onto it to achieve precise cuts. 3. Band Saw: Another commonly used machine for steel round bar cutting, the band saw features a rotating toothed metal band that moves on two pulleys. The round bar is secured in a vise, and the band saw is adjusted to the desired angle and speed. The bar is then fed into the blade, resulting in smooth cuts. 4. Torch Cutting: For thicker steel round bars, oxy-fuel torch cutting is suitable. This method involves using a torch that combines oxygen and fuel gas, like acetylene, to produce a high-temperature flame. The round bar is heated until it becomes molten, and then a separate stream of oxygen is directed onto the heated area, causing rapid oxidation and enabling a cut. Irrespective of the chosen method, it is crucial to adhere to proper safety measures, including wearing protective goggles and gloves, and ensuring a stable work surface. Furthermore, using the appropriate cutting tools and techniques for the specific type of steel being cut is vital to achieve clean and precise results.

- Q: Are steel round bars available in different colors?

- No, steel round bars are typically available in a silver or gray color as they are made from alloyed iron and carbon.

- Q: What are the different cutting methods for steel round bars?

- Depending on the specific requirements and available equipment, there are various cutting methods that can be used for steel round bars. Here are some of the most commonly used ones: 1. Sawing: Sawing is a traditional and basic method of cutting steel round bars. It involves using a saw blade with teeth to cut through the metal. This can be done manually with a hacksaw or with the assistance of a bandsaw or circular saw. Sawing is a versatile method suitable for both small and large-scale cutting projects. 2. Shearing: Another commonly used method is shearing. It utilizes a shear machine or hydraulic press to apply high force and cut through the metal. Shearing is particularly effective for cutting thick or heavy-duty steel bars. 3. Abrasive cutting: For steel round bars with irregular shapes or precision cutting projects, abrasive cutting is often employed. This method involves using an abrasive wheel or disc to grind away the metal and create the desired cut. It can be performed manually with a handheld grinder or with the assistance of an abrasive cut-off saw. 4. Flame cutting: Also known as oxy-fuel cutting, flame cutting employs a combination of oxygen and a fuel gas to create a high-temperature flame that melts and cuts through the steel. This method is commonly used for cutting thick steel bars or shaping metal. 5. Plasma cutting: Plasma cutting is an advanced method that utilizes a plasma torch to cut through the steel. The torch generates a high-velocity jet of ionized gas, which melts and removes the metal. Plasma cutting is often preferred for precision cutting due to its greater control and ability to produce cleaner cuts compared to other methods. It is important to consider factors such as the thickness and hardness of the steel round bar, desired precision of the cut, and available equipment when selecting a cutting method. Consulting with a professional or experienced metalworker is recommended to determine the most suitable method for a specific project.

- Q: Can steel round bars be used in the automotive industry?

- Indeed, the automotive industry does make use of steel round bars. These bars are frequently employed in various capacities within the industry. Specifically, they are commonly utilized in the fabrication of different components, including axles, drive shafts, suspension parts, and steering components. The reason for their popularity lies in their exceptional attributes, such as high strength, durability, and resistance to wear and tear. These qualities enable them to withstand the rigorous conditions and heavy loads that automotive components are subjected to. Moreover, the ease with which steel round bars can be machined and welded facilitates efficient production and assembly processes in the automotive sector. Consequently, steel round bars are highly regarded as a dependable and cost-effective option for automotive manufacturers, making them a favored material in the industry.

- Q: What are the different grades of stainless steel round bars for marine applications?

- For marine applications, stainless steel round bars come in various grades. The commonly used grades are 304, 316, and 316L stainless steel. Grade 304 stainless steel is a versatile alloy known for its good corrosion resistance, high strength, and excellent formability. It is often utilized in marine applications that require moderate corrosion resistance. Grade 316 stainless steel is similar to grade 304 but contains additional molybdenum. This enhances its corrosion resistance, especially against chlorides and other aggressive marine environments. Grade 316 is preferred in marine settings that demand increased resistance to corrosion. Grade 316L stainless steel is a low carbon version of grade 316. Its resistance to sensitization and intergranular corrosion is further improved. This makes it highly suitable for marine applications that involve welding, reducing the risk of corrosion at the welds. Apart from these grades, there are specialized stainless steel alloys like duplex stainless steel. These alloys combine the advantages of austenitic and ferritic stainless steels, offering even greater corrosion resistance and strength. They are suitable for demanding marine applications. When choosing stainless steel round bars for marine applications, it is crucial to consider specific environmental conditions such as exposure to saltwater, chemicals, or high temperatures. Seeking guidance from a materials specialist or referring to industry standards can help ensure the appropriate grade is selected for the specific marine application.

- Q: How do steel round bars perform under fatigue loading?

- High-quality steel round bars generally exhibit excellent performance when subjected to fatigue loading. Fatigue loading refers to the repetitive application of stress or strain on a material, which can eventually cause failure. The outstanding fatigue strength of steel round bars is well-known. This refers to their ability to withstand cyclic loading without developing cracks or failures. This exceptional fatigue strength can be attributed to the inherent properties of steel, including its high strength, ductility, and toughness. During fatigue loading, steel round bars undergo cyclic stress, resulting in alternating tension and compression. Nonetheless, steel possesses a relatively high endurance limit, also known as the fatigue strength coefficient. This limit determines the maximum stress level that the material can endure without failure, even under cyclic loading. Moreover, steel round bars demonstrate commendable resistance to fatigue crack propagation. In the event that a crack does initiate due to cyclic loading, it is less likely to propagate or grow rapidly in comparison to other materials. This can be attributed to the material's ability to absorb energy and redistribute stress, thus impeding crack growth and preventing failure. Nevertheless, it is essential to consider that the performance of steel round bars under fatigue loading can be influenced by various factors. These factors include the specific type and grade of steel utilized, the manufacturing process, surface conditions, and the applied stress or strain levels. Therefore, it is crucial to adhere to industry standards and guidelines when designing and implementing steel round bars to ensure optimal performance and safety under fatigue loading.

- Q: Are steel round bars suitable for agricultural applications?

- Steel round bars are indeed appropriate for agricultural applications. Due to its robustness and endurance, steel proves to be a resilient material capable of enduring the challenging conditions frequently encountered in agricultural settings. The utilization of steel round bars in agriculture encompasses a multitude of purposes, including the construction of fences, gates, and animal enclosures. Moreover, they are frequently employed in the creation of structures like barns and storage sheds. Furthermore, steel round bars can serve as dependable support beams or posts for agricultural machinery and equipment. The reliability and adaptability of steel render it an excellent choice for agricultural applications.

- Q: What is the yield strength to tensile strength ratio of a steel round bar?

- The yield strength to tensile strength ratio of a steel round bar is typically around 0.85.

- Q: 20# difference between round bar and A3 round bar, can they be used separately?

- 20# rounds are plain carbon steel, as well as 10#, 20#, 45#, etc.A3 round bar is Q235, grade is ABCDE, etc., commonly used is Q235BIn use performance, 20# hardness is strong, but the elasticity is bad, welding performance is poorA3 hardness is less, but good elasticity, good welding performanceAs for specific can not be replaced, mainly depends on the use of places.

- Q: Can steel round bars be used in the manufacturing of couplings?

- Yes, steel round bars can be used in the manufacturing of couplings. Steel round bars are commonly used in various industrial applications due to their strength, durability, and versatility. Couplings are mechanical devices that connect two shafts together in order to transmit power or allow for the misalignment of the shafts. Steel round bars can be machined, formed, or welded to create different types of couplings, such as rigid couplings, flexible couplings, or universal couplings. The use of steel round bars in manufacturing couplings ensures that the couplings have high tensile strength and can withstand heavy loads and torque. Additionally, steel round bars can be heat-treated to enhance their mechanical properties, making them suitable for different operating conditions and environments. Therefore, steel round bars are a popular choice for the manufacturing of couplings.

Send your message to us

ALLOY HOT ROLLED ROUND BAR JIS/GB/DIN STANDAR

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords