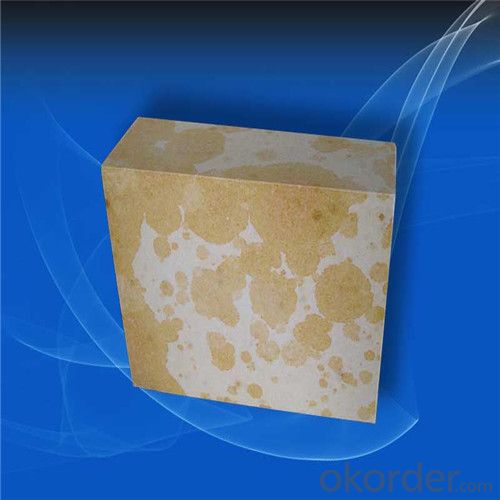

Competitive Price Acid-Resisting Silica Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Acid resistance brick is specially used as lining in reaction tower of chemical plants, fertilizer factories and sulfuric acid industries or inside the corrosion-resistance pool and ditch.

Features

Strong acid and alkali resistance

Size available as customer’s requirement

Applications

It is widely used in corrosion-resisting liner of petroleum, chemical industry, chemical fertilizer, food, chemical fiber, laboratory, pharmacy, papermaking, generate electricity, smelt, electroplating room, and the inner corrosion-resisting lining of tower, pool, pot, tank, etc. It is also used for sewage conduit and open-air floor.

Acid Resistance Brick Data Sheet

Classification Temperature (℉/℃) | 3000/1650 |

Bulk Density (g/cm3 ) | ≤1.0 |

Thermal Conductivity | |

800℃, W/m.K | ≤0.39 |

1000℃, W/m.K | ≤0.43 |

1200℃, W/m.K | ≤0.48 |

Reheating Linear Change (%) | 1550℃×12h |

≤0.9 | |

Chemical Composition (%) | |

Al2O3 | ≥75 |

Fe2O3 | ≤0.5 |

Packaging & Shipping

Packaging Details:Be packed in fumigated wooden pallets

Delivery Detail: 30 days after order

- Q: Physical solid waste disposal

- Reduce crack production and improve yield. The amount of addition is related to the shape and weight of the brick. The bricks can be added to 20% weight less than 25kg; bricks above 25kg can be added to 30%; for the specific type of brick can be added 30%. into waste silica brick should pay attention to this problem

- Q: The hot blast stove when the temperature did not rise against the brick interface decreased

- How to keep the brick masonry temperature not lower than 600 DEG C, while the exhaust temperature is not higher than 400 DEG C.

- Q: Why will expand when heated brick

- After high temperature after the formation of tridymite and cristobalite and quartz and a small amount of residual glass phase, quartz heating to 220-240 DEG C, in a certain degree of thermal expansion, brick maximum expansion occurs in 100~300 DEG C, 300 expansion before the total amount of expansion is about 70%~75%.

- Q: How much is the highest melting point of silicon?

- Mainly used for partition, carbonization chamber of coke oven and combustion chamber open hearth furnace regenerator and a sediment chamber, soaking furnace, glass melting furnace refractories and ceramic kiln, kiln vault and other load-bearing parts. Also used for high temperature bearing part of hot blast stove and acid open hearth furnace

- Q: The brick is mainly used in the place?

- Partitions used in coking and combustion chambers for coke ovens

- Q: The United States of our brick anti-dumping duties?

- . According to the relevant legal procedures, the United States International Trade Commission will make a final ruling on the anti dumping industrial injury before January 6, 2014, if an affirmative determination, the U.S. Department of Commerce will be involved in product release tax anti-dumping order.

- Q: Can iron oxide be used as refractory material?

- Iron oxide can not be used as refractory material, but it can be used as refractory additive. Iron oxide can be used as pigment

- Q: Why is the three oxidation of two silicon is very harmful impurities in silica brick

- Can generate the material needs is the best way to see the impurity problem!! the first consideration is whether can get the material impurities with what method choice after the time! Miscellaneous reactions cannot have new impurity formation! Selected cannot and need material reaction reagent!

- Q: The chemical composition of silica brick and its physicochemical index?

- ????Al2O3 SiO2??????fe2o3??????cao???????r2o93~98?0.5~2.5?;;?0.3~2.5??0.2~2.7;??1~1.5;

- Q: High temperature refractory material?

- Basic refractories in Magnesium Oxide and calcium oxide as the main component, the main products are magnesia brick, magnesia chrome brick, magnesia zirconia brick, magnesia brick, magnesia spinel brick, magnesia calcium brick, dolomite brick and the latest development of magnesia spinel brick and so on. With Magnesium Oxide (MgO) more than 80% of the refractory brick called magnesia brick,

Send your message to us

Competitive Price Acid-Resisting Silica Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords