Mark & model : Reliable structure, easy installation, convenient packing and transportation, structural waterproofing, heat insulation, tight structure, moisture resistance and anti-corrosion, adjustable area and flexible layout.

Origin : Asia and Pacific Area China

Quality standard : International

Submit date : 2013-09-23

H.S.Classification : Furniture & Toys Furniture 9406 Prefabricated buildings

Product profile : A4-type Prefabricated House

Size: 5050*n*1224+2*1100*2450mm(H) (n refers to units)

Notes of Product:

The most economic and suitable mobile house for medium-and-small-sized dormitory and office building enjoys flexible layout with the house span of around 5m and expanded length of 1.2m standard module. As one of the temporary houses that are featured to have the shortest installation period, the 130㎡A4 prefabricated house could be set up by four workers per day. The A4 prefabricated house is featured to have the most economic size for the transportation that 330㎡(floor area) mobile house could be held in the 40ft container. As the temporary house enjoying the best performance of disassembly, the A4 prefabricated house could be reused for about ten times.

Quality Standard: Industrial standard

Origin: China

Commodity Classification: A4 prefabricated house

Descriptions:

1.The A4 prefabricated house is equipped with cold-formed thin-walled light steel structure and the walls and roofs are covered by color steel composite sandwich plate.

2.The steel structural system ensures the house the excellent windproof capacity of standing up 86.4km/h and keeps perfect integration when the earthquake with intensity of 7 degree occurs.

3.The color steel composite sandwich board is composed of steel plate and polystyrene through adhesive which is proved to have excellent fireproof and heat-insulating performance with advantages of different materials.

4.All components of the house are prefabricated standardly. The product enjoys easy installation and disassembly as well as flexible layout and functions through free adjustment of the number and location of doors, windows and indoor partition walls.

5.The complete disassembly of all components of the house ensures the easy transportation and cuts the cost.

6.The house is quite light and easy to install. Four skilled workers shall install about 100㎡area of the house in one day.

7.All components and materials could be recycled and the service time of the galvanized components reaches up to 20 years. No construction waste occurs during the usage.

8.The large-slope roofing adopts structural waterproof design to improve the air and water tightness of the house.

Features: Safe and Reliable Structure:

The house could stand up to force 10 wind, equivalent to the designed wind pressure of 0.45KN/㎡ (Chinese Standard).

2. Simple and Convenient Installation:

A standardized house of 66.74㎡could be set up by four skilled workers within four hours. Simple tools and no power supply shall be used during the installation process.

3. Easy Packing and Transportation:

The product is specially designed for the best loading mode and the convenience of packing and transportation. The 40ft container could hold the house product of about 330㎡ (floor area).

Structural Waterproofing:

The roof adopts the structural waterproof design and no nail is exposed on the external roof; no need of extra waterproof treatment to avoid the leaking risk.

Thermal Insulation:

The core material of the enclosing walls is polystyrene, the effective heat-insulating material with heat conductivity no more than 0.041W/m.K.

6. Firm Structure, Moisture Resistance and Anti-corrosion

The structural design of the house is appropriate and the metal frame is galvanized; the color steel composite sandwich board is proved to have excellent performance of moisture resistance and anti-corrosion.

7. Adjustable Area and Flexible Layout

The usable area of the house could be adjusted by increasing or decreasing the numbers of the modular unit in the lengthwise direction; the flexible layout could be fulfilled by the free installation of doors, windows and partition walls.

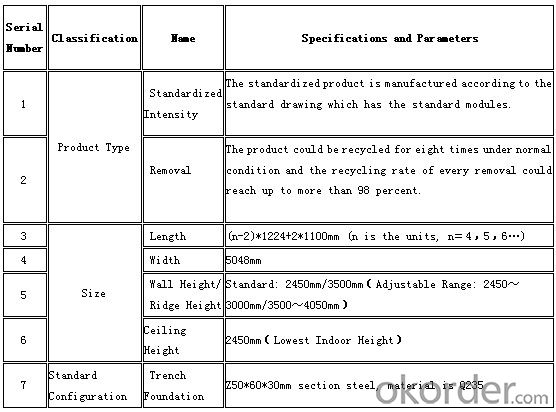

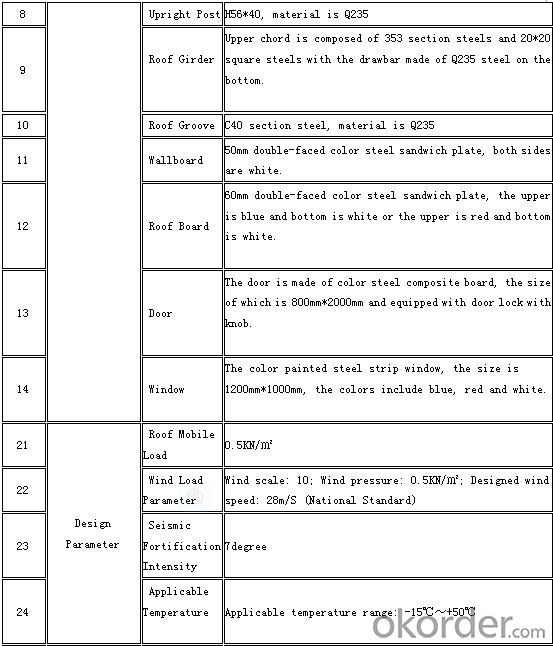

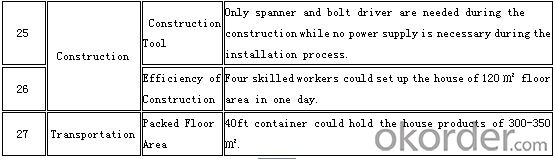

Parameters: