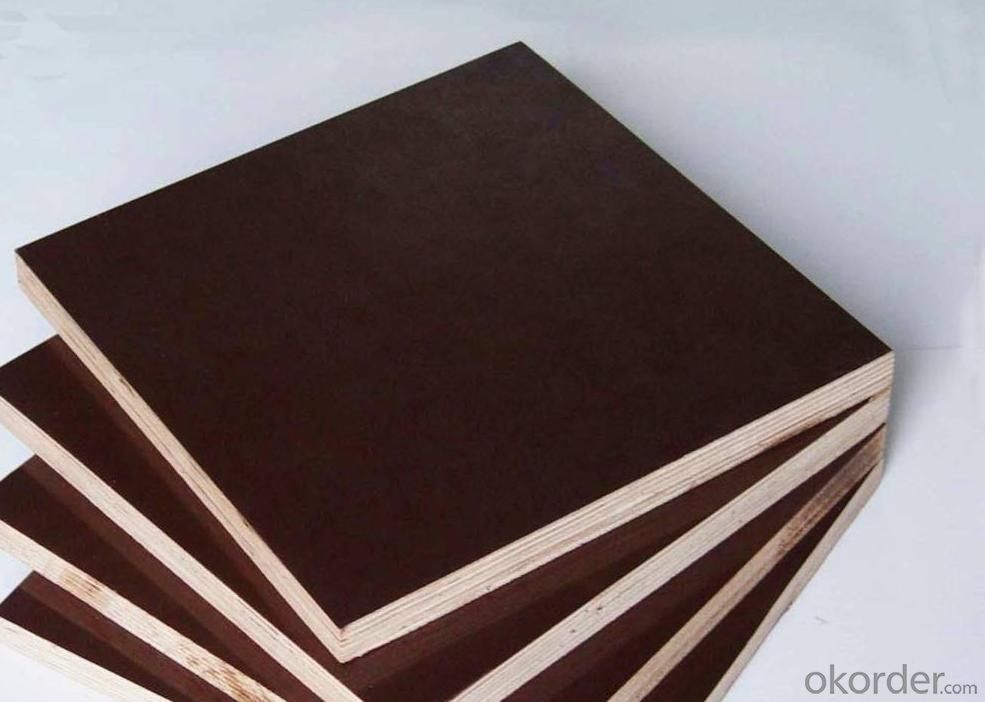

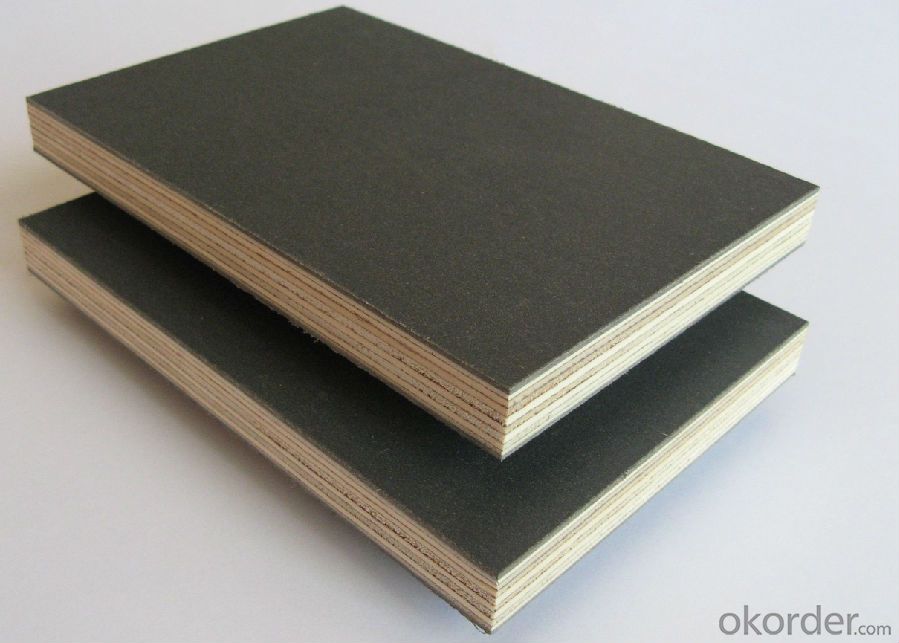

A Grade Commercial Plywood Furniture - Painted Plywood Floors Constructed from Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 900 pc

- Supply Capability:

- 60000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

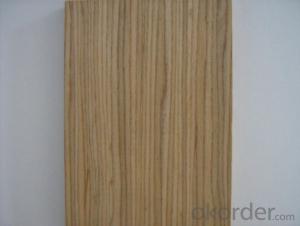

Name | commercial plywood | |

Size | 1220x2440mm,1250x2500mm or as your request | |

Thickness | 2.5mm—30mm | |

Thickness Tolerance | ≤6mm | ±0.2mm to ±0.3mm, |

6mm—30mm | ±0.4mm to ±0.5mm | |

Core | Poplar,Eucalyptus, hardwood , combi or as agreed. | |

Face/Back | okoume,bingtangor,poplar, keruing, pine,beech,oak etc | |

Glue | MR, WBP(E0, E1, E2). | |

Grade | BB/BB,BB/CC ,CC/CC or As Agreed | |

Moisture | To be 8%-14% at time of shipment. | |

Usange | Decoration, Furniture, package | |

Package | Inter packing: 0.20mm plastic bag. | |

Outer packing: pallets are covered with plywood or carton and then steel for strength. | ||

Conveyance | 20’GP | 8pallets/ 22m³ |

40’GP | 16pallets/ 42m³ | |

40’HQ | 18pallets/53m³ | |

Delivery time | Within 15 days on receipt of deposit or original L/C. | |

Min Order | 1X40’FCL | |

Price terms | FOB, CNF, CIF | |

Payment terms | L/C at sight, T/T30% as deposit | |

Supply ability | 3000 cubic meters/month | |

Packaging & Delivery

| Packaging Detail: | Inner with waterproof plastic bag, outside with 3mm plywood and carton, then fastened with 3'x6' sheet iron and packed with pallets |

| Delivery Detail: | 15 days after receiving your deposit or LC |

Specifications

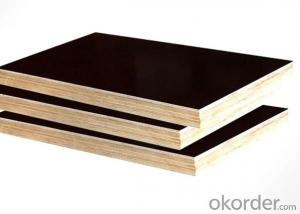

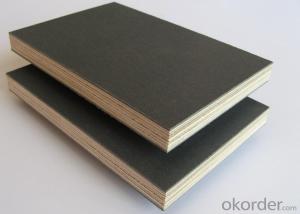

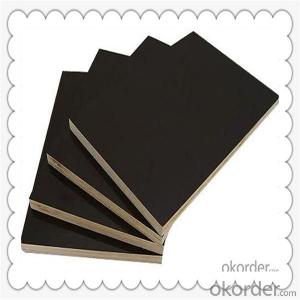

Film Faced Plywood manufacturer

Size: 1220x2440/1250x2500mm

F/B: Black/Brown/red

Core: Poplar, Hardwood

Glue: WBP, Melamine

- Q: National standards for decorative veneer veneer plywood performance requirements

- Its physical and mechanical performance indicators are: moisture content, surface bonding strength, impregnation stripping

- Q: What is the composition of the plywood?

- Glue plywood usually refers to the plywood or multi-layer board, that is, with the same thickness of two or more layers of veneer plus glue from high temperature suppression.

- Q: triple? Nail gun Self-tapping screws? Cork Or other?

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences

- Q: What are the processing defects of plywood?

- Patched Plywood Repaired plywood Defects Plywood that has been repaired with a filler or veneer patch.

- Q: What are the key points for plywood selection?

- if you do not consider the panel pattern and color, should also be based on the environment and reasonable cost Selection of plywood grade, category

- Q: Plywood in the decoration works how to use

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each other, usually its table and the inner plate symmetrically arranged in the center layer or plate on both sides.

- Q: What is the density of plywood?

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q: What is the amount of construction works used for this plywood?

- The second type of plywood is water resistant plywood, can be immersed in cold water and short time hot water immersion;

- Q: What are the advantages and disadvantages of plywood?

- the construction is convenient, not Qu Qiao, stripes tensile mechanical properties. light weight, clear lines, insulation, strength, not easy to deformation.

- Q: Today, most of the furniture is made of wood, pine, bakelite and popla

- As these high quality woods become increasingly scarce and expensive, people begin to make furniture with easier access to wood, and those good wood is already very rare

Send your message to us

A Grade Commercial Plywood Furniture - Painted Plywood Floors Constructed from Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 900 pc

- Supply Capability:

- 60000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords