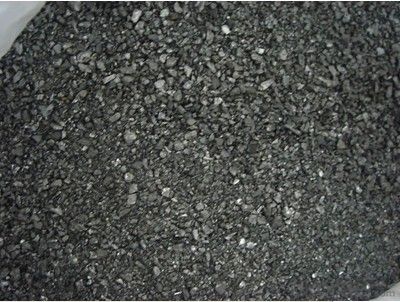

95% Carbon Calcined Anthracite Coal - Raw Materials for Refractory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Calcined Anthracite Coal For Sale

Calcined Anthracite Coal is widely used in steel making and casting.

General Specification

SPECIFICATION | |||||

F.C.% | 95min | 94min | 93min | 92min | 90min |

ASH % | 4max | 5max | 6max | 7max | 8max |

V.M.% | 1 max | 1max | 1.5max | 1.5max | 1.5max |

SULFUR % | 0.5max | 0.5max | 0.5max | 0.5max | 0.5max |

MOISTURE % | 0.5max | 0.5max | 0.5max | 0.5max | 0.5max |

Our Advantage:

--Low ash and sulfur contain

--Reduce needs for expensive melt additives.

--Increased dissolution rate over anthracite blends

--Reduces slagging time, labor and disposal cost

--Extends the life of the furnace lining, reduce maintenance cost and increase production yield.

Our Services

1,Reliable service that make you feel purchasing is more easier

2,Great supply capability with competitive price.

3,Carefull Inspection to ensure the quality of cargo

4.Supplying different kinds of carbon additives to meet your demand

FAQ

1.What is the min order of Calcined Anthracite Coal?

20 Tons is acceptable.

2. How could you assure the quality of Calcined Anthracite Coal?

We will provide quality certification for each shippment. And we have ISO certification for this item. You could also visit our factory to control quality if possible. Or we could ask the third party, such as, SGS, to test the cargo.

3. Is your price more competitive comparing to manufacturer's?

Generally, we could provide reasonable and competitive price. Please feel free to send us an inquiry if you have.

4. Could I visit your factory?

Welcome to visit our factory.

5. What kind of payment method do you use?

Generally, T/T, L/C at sight. But if you have special requirement, please feel free to tell us. Let's talk about it.

- Q: What is refractory brick?

- Capability1. Refractory brick is also known as firebrick. It is faint?yellow or brownish. Refractory brick with 770 ℃ at high temperatures is called for short firebrick. It is mainly used for building and smelting furnace. It is a refractory material made by fring refractory clay or other refractory material.

- Q: What are the characteristics of thealuminium oxide refractory?

- Alumina refractory are characterized by uniform granularity, mobility, good dispersity. And it has good acid and alkaline slag erosion resistance, high strength, abrasion resistance, high melting point, erosion resistance , anti-flush and excellent thermal shock resistance.

- Q: What's the poured refractory material?

- Frequently used poured refractory material: AZS brick, corundum brick, direct-bonded?magnesia-chrome?bricks, carborundum brick, silicon nitride bonded silicon carbide brick, nonoxide refractories like nitride, silicide, sulfide, boride and carbide, and oxide refractories like calcium oxide, chromium hemitrioxide, alumina, magnesium oxide and beryllia.

- Q: What is the material of fire resistant glass reinforced plastics grating?

- What is the material of fire resistant glass reinforced plastics grating?

- Q: What's the material of electrical fire prevention board?

- Industrial electrical fire prevention board is usually made of flame-retardant fiberboard, and its main purpose is for fire prevention and thermal insulation. Iron plate is electrically conductive with good thermal conductivity, which will cause the result that the equipment is not insulated and suffers larger superheating surface!!!! So the material uses the flame-retardant fiberboard. Hope my answer is helpful for you.

- Q: How is refractory material made?

- It is made by mixing and processing of various refractories.

- Q: What does refractory mean?

- Basic refractory material generally refers to Magnesium Oxide or Magnesium Oxide and calcium oxide as the main component of refractory materials. This kind of refractory material has higher refractoriness and strong resistance to alkaline slag.

- Q: What are the disadvantages of the refractory industry?

- The rapid development of continuous casting technology allows Hua Heng refractories to be improved in variety and quality. The development of refractory for continuous casting has a significant impact on the production of continuous casting and quality of continuous casting billet. Constructing and putting Baosteel into action has greatly pushed the improvement of the refractory technology. Continuous casting refractory is an important part of the continuous casting machine. In addition to the general characteristics of refractories, it is also required functions that can purify molten steel, improve the quality of steel, stabilize temperature and composition of the molten steel, control and regulate the molten steel flow. Therefore, it is known as functional refractories. Continuous casting Refractories include: (1) ladle refractory - ladle lining, permanent lining and ventilation components; (2) tundish refractories - permanent lining, coating, insulating plates, clad etc; (3 ) functional refractories - long nozzle for non-oxidizing casting, submerged nozzle, monolithic stopper, sliding gate; (4) ceramic purifier for purifying molten , slag dam, alkaline paint and horizontal separating ring and gate board for continuous casting.

- Q: what are the types of piping insulation material fire?rating?

- Pipe insulation material Fire rating: heat conductivity coefficient(at room temperature) 0.025 grade non-combustible Class A low temperature bending ≤ 5000 breaking elongation 5,000 specifications 5000 anti-bending?strength 5000 compressive?strength 5000 special brand of high use temperature -250 ~ 150 ℃ core material, phenolic foam, form, stratiform, shape,flake.

- Q: What are the advantages of refractory material?

- Jingute WHL type, GDS type

Send your message to us

95% Carbon Calcined Anthracite Coal - Raw Materials for Refractory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords