9.625in UltraLock Casing, 12.7mm, Corrosion-Resist

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

9.625" CO₂ Injection Casing

CCUS Specialist: Handles 10,000ppm CO₂ environments

Tech Edge:

Internal Cladding: 1.0mm Inconel 625 layer

pH Resistance: 3.5-11.0

Expansion Joints: Accommodate 1.2% volume changes

Real-World Use:

At project, these casings maintained integrity through 50+ injection cycles over 8 years.

Key Specs:

Max OD: 244.5mm (9.625")

Pressure: 6,000psi working pressure

Coupling: Tapered trapezoidal thread

Offer: Free CO₂ corrosion calculator + 15-year performance guarantee

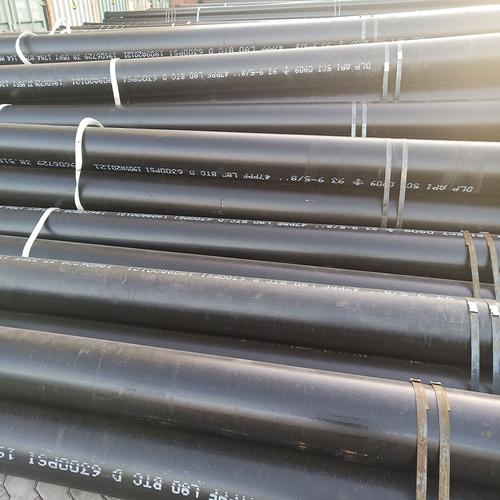

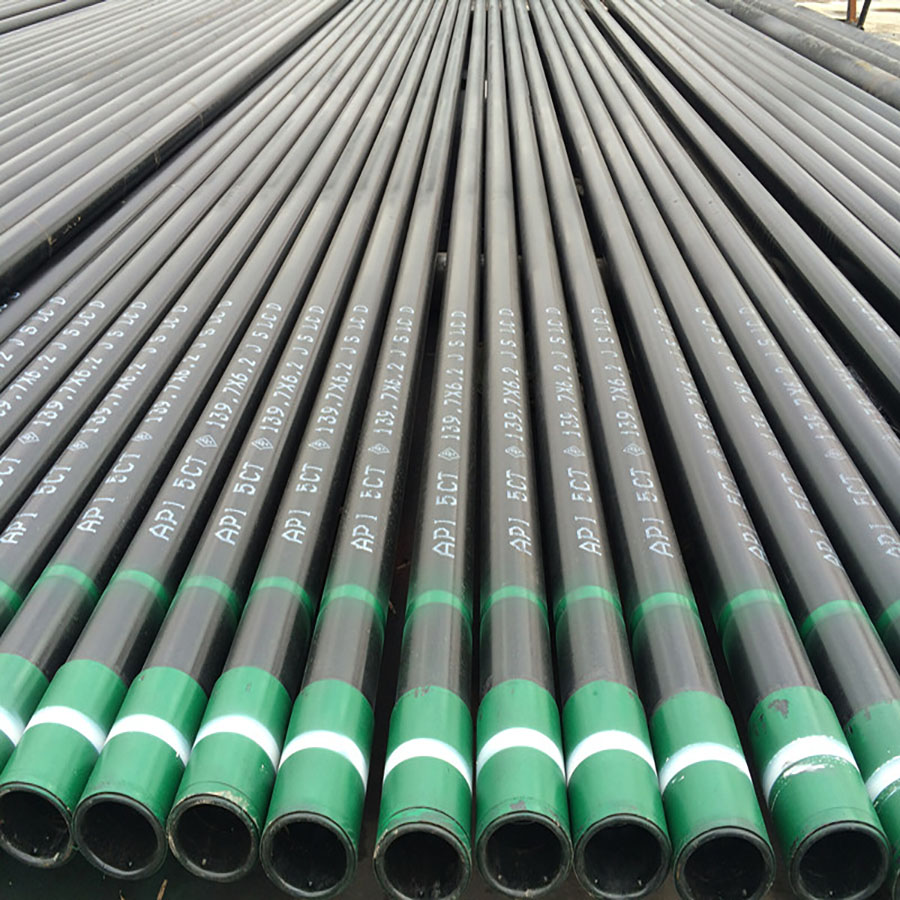

Petroleum Casing Product Information

1. Product Overview

J55 Steel Deep Well Casing, P110 High-Grade Drilling Casing

petroleum casing is strictly manufactured in compliance with API 5CT standards, covering mainstream steel grades such as J55, N80, and P110. It is suitable for wellbore reinforcement and formation isolation in onshore oilfields, offshore platforms, and complex geological environments, ensuring lifecycle safety of oil and gas wells.

2. Technical Specifications

Size Range:

Outer diameter 114.3 mm (4.5") to 508 mm (20"), wall thickness 6.2-25.4 mm, tolerances conform to API 5CT standards (outer diameter ±0.5%, wall thickness ±10%).Mechanical Properties:

J55 Grade: Yield strength ≥379 MPa, tensile strength ≥517 MPa;

P110 Grade: Yield strength ≥758 MPa, tensile strength ≥965 MPa;

Collapse resistance: N80 Grade ≥80 MPa, P110 Grade ≥138 MPa (tested per ASTM A370).

Thread Performance:

API round thread (BTC) sealing pressure ≥20 MPa;

Premium connections (e.g., BGT2) helium leakage rate ≤1×10⁻⁶ cm³/s (tested per ISO 13679 CAL IV).

3. Chemical Composition (Example: L80 Grade)

| Content | 0.25% | 1.20% | 0.45% | 0.50% | 0.25% | 0.020% | 0.010% |

| Note: Cr-Mo alloy design enhances H₂S corrosion resistance (H₂S partial pressure ≤0.3 kPa). |

4. Application Scenarios

High-Temperature & High-Pressure Wells:

L80-13Cr material withstands 180°C and CO₂ partial pressure ≤1 MPa (per NORSOK M-001).Shale Gas Horizontal Wells:

TP140TT high-collapse casing with internal pressure resistance ≥105 MPa, compatible with multi-stage fracturing.Deepwater Offshore Wells:

9-5/8" casing passes 30 MPa external pressure test, suitable for 3,000-meter water depth.

5. Production Process

Material Smelting:

Electric Arc Furnace (EAF) + LF refining, sulfur/phosphorus ≤0.015%;

Continuous casting billet Φ180-400 mm, central segregation ≤Class C 1.0.Hot Rolling:

Three-roll retained mandrel mill, wall thickness uniformity ≤5%;

Online spray cooling, final rolling temperature 900±20°C.Heat Treatment:

Quenching (920°C water cooling) + Tempering (620°C air cooling), hardness 22-32 HRC;

Sour-service pipes use HWQ process, grain size ≥ASTM 7.Quality Inspection:

100% ultrasonic testing (UT) for longitudinal defects (sensitivity Φ1.6 mm flat-bottom hole);

Full-length hydrostatic test (50-100 MPa, holding ≥10 seconds);

Drift test with API drift mandrel (100% pass rate).

- Q: What does seamless steel tube mean? What are the main uses? What are the classifications?

- Electrical, gas, water, power, fluid, pipe.The main production process for hot rolling seamless steel tube (the main inspection):Tube preparation and check delta to billet heating, heating, rolling, perforated pipe, steel pipe and heat treatment, diameter (minus) Delta to finished tube straightening, finishing and inspection of delta (nondestructive, physicochemical, Taiwan inspection and warehousing)Main production process of cold rolled (drawn) seamless steel tube:Blank preparation, pickling, lubrication, cold rolling (drawing), heat treatment, straightening, finishing and inspection

- Q: What is the role of steel pipes in the mining and extraction of minerals?

- The mining and extraction of minerals heavily rely on steel pipes, which have a vital role to play. These pipes are extensively utilized in diverse mining operations for the transportation of fluids like water and slurry. Moreover, they are employed to offer structural reinforcement and ventilation within underground mines. A fundamental application of steel pipes in mining is the transportation of water and slurry. Water is an essential component in the mining process, serving purposes such as dust suppression, ore processing, and site rehabilitation. The creation of a pipeline network using steel pipes enables the efficient transfer of water from its source, such as a reservoir or dam, to various areas within the mine. Similarly, slurry, a mixture of crushed minerals and water, is frequently conveyed through steel pipes to processing plants or tailings dams. Structural support is another critical function fulfilled by steel pipes in underground mines. The extraction of valuable mineral deposits necessitates the construction of tunnels and shafts. To endure the immense pressure exerted by the surrounding rock and prevent collapses, these underground excavations require reinforcement. Steel pipes, acting as support structures like roof bolts and rock bolts, strengthen the walls and roofs of these tunnels and shafts, thereby ensuring miner safety and maintaining the stability of the mine structure. Furthermore, steel pipes are employed in ventilation systems within underground mines. Proper ventilation is vital for mining operations, ensuring a continuous supply of fresh air, removal of harmful gases, and control of temperature and humidity levels. Steel pipes are utilized to create ventilation shafts and ducts, facilitating the smooth flow of air throughout the mine. This aids in preventing the accumulation of toxic gases, dust, and excessive heat, thereby maintaining a safe and healthy working environment for miners. To summarize, steel pipes are indispensable for the mining and extraction of minerals. They facilitate the transportation of fluids, offer structural reinforcement in underground mines, and contribute to efficient ventilation systems. The absence of steel pipes would significantly impede the efficient and safe extraction of minerals from mines.

- Q: What is the average lead time for manufacturing steel pipes?

- The average lead time for manufacturing steel pipes can vary depending on several factors such as the complexity of the design, size of the order, and the specific production capabilities of the manufacturer. Typically, it can range from a few weeks to a few months.

- Q: Can steel pipes be used for underground heating systems?

- Yes, steel pipes can be used for underground heating systems. Steel is a durable and robust material that can withstand the pressure and temperature requirements of heating systems. Additionally, steel pipes are resistant to corrosion, which is crucial for underground applications where exposure to moisture and other elements is common.

- Q: How are steel pipes used in the construction of water supply systems?

- Steel pipes are commonly used in the construction of water supply systems due to their durability and strength. They are often used to transport water from the source to treatment plants, as well as for distribution to homes and businesses. Steel pipes are resistant to corrosion, which ensures the quality of the water and the longevity of the system. Additionally, their high pressure-bearing capacity makes them suitable for water supply networks that require efficient and reliable transportation of water.

- Q: How do steel pipes handle abrasive materials?

- Steel pipes are highly resistant to abrasive materials due to their strong and durable nature. The smooth interior surface of steel pipes minimizes friction and wear caused by abrasive materials, making them an ideal choice for handling such substances.

- Q: What's wrong with the 3PP anticorrosive steel tube?

- Most of the large pipes in our country use 3PE coating, and 3PP and 3PE coating belong to multilayer coating system. It consists of epoxy powder, intermediate layer adhesive and outer layer of PP (polypropylene) jacket.

- Q: How are steel pipes connected to other materials like concrete or plastic?

- Steel pipes can be connected to other materials like concrete or plastic through various methods such as welding, flanges, threaded connections, or using specialized fittings. These connections ensure a secure and durable bond between the steel pipe and the other material, allowing for effective transfer of fluids or structural support.

- Q: How are steel pipes used in the mining industry?

- Steel pipes are commonly used in the mining industry for various purposes such as transporting water, slurry, and other materials, as well as for ventilation and support systems in underground mines.

- Q: What are the different types of steel pipe coatings for corrosion protection?

- Some of the different types of steel pipe coatings for corrosion protection include epoxy coatings, polyethylene coatings, polyurethane coatings, and zinc coatings.

Send your message to us

9.625in UltraLock Casing, 12.7mm, Corrosion-Resist

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Related keywords