7in ExtremeGrip Casing: 10.36mm WT, Fast Ship

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

7" CementLock™ Production Casing

Cement Bond Booster: Diamond-pattern surface increases bonding strength by 40%

Design Highlights:

External Grooves: 1.2mm depth spiral pattern

Centralizer Slots: Pre-cut every 2.5m

Easy Cutting: Laser-marked cut points

Driller's Choice:

Oklahoma operators report 50% reduction in cement channeling issues. The grooves help maintain 360° cement coverage in deviated wells.

Parameters:

Weight: 29.0kg/m

Drift Diameter: 157.1mm

Thread Type: API Short Round

Help: Free cementing best practices guide + 24/7 engineering support

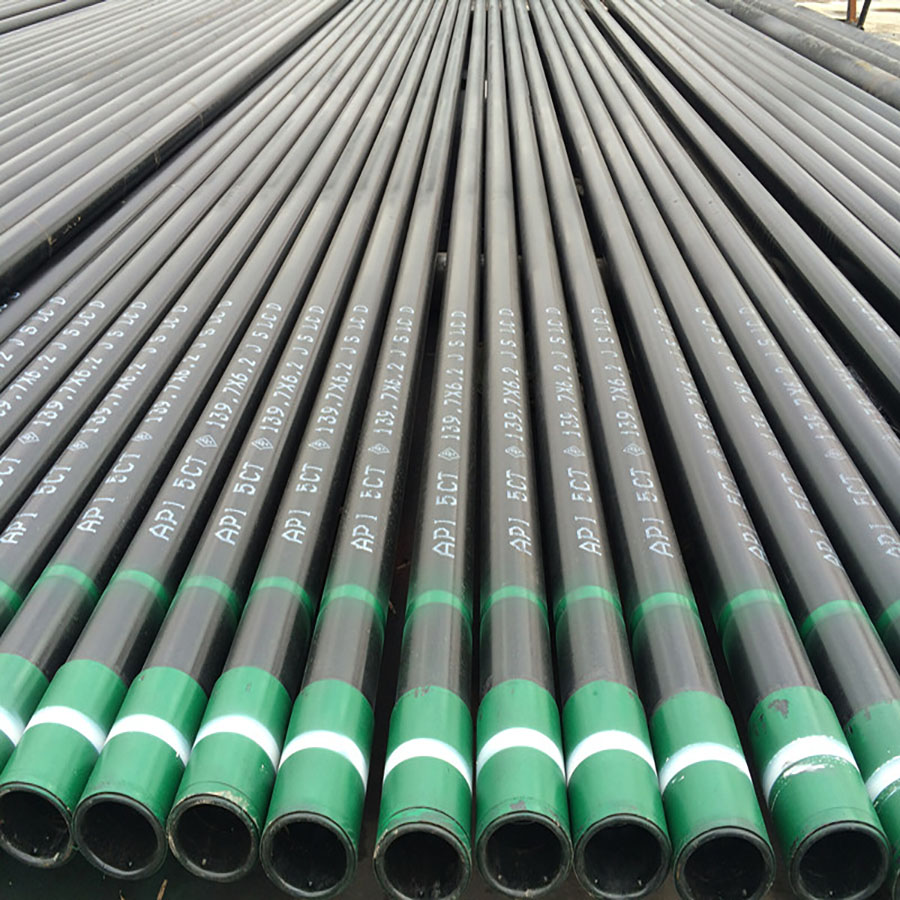

Petroleum Casing Product Information

1. Product Overview

J55 Steel Deep Well Casing, P110 High-Grade Drilling Casing

petroleum casing is strictly manufactured in compliance with API 5CT standards, covering mainstream steel grades such as J55, N80, and P110. It is suitable for wellbore reinforcement and formation isolation in onshore oilfields, offshore platforms, and complex geological environments, ensuring lifecycle safety of oil and gas wells.

2. Technical Specifications

Size Range:

Outer diameter 114.3 mm (4.5") to 508 mm (20"), wall thickness 6.2-25.4 mm, tolerances conform to API 5CT standards (outer diameter ±0.5%, wall thickness ±10%).Mechanical Properties:

J55 Grade: Yield strength ≥379 MPa, tensile strength ≥517 MPa;

P110 Grade: Yield strength ≥758 MPa, tensile strength ≥965 MPa;

Collapse resistance: N80 Grade ≥80 MPa, P110 Grade ≥138 MPa (tested per ASTM A370).

Thread Performance:

API round thread (BTC) sealing pressure ≥20 MPa;

Premium connections (e.g., BGT2) helium leakage rate ≤1×10⁻⁶ cm³/s (tested per ISO 13679 CAL IV).

3. Chemical Composition (Example: L80 Grade)

| Content | 0.25% | 1.20% | 0.45% | 0.50% | 0.25% | 0.020% | 0.010% |

| Note: Cr-Mo alloy design enhances H₂S corrosion resistance (H₂S partial pressure ≤0.3 kPa). |

4. Application Scenarios

High-Temperature & High-Pressure Wells:

L80-13Cr material withstands 180°C and CO₂ partial pressure ≤1 MPa (per NORSOK M-001).Shale Gas Horizontal Wells:

TP140TT high-collapse casing with internal pressure resistance ≥105 MPa, compatible with multi-stage fracturing.Deepwater Offshore Wells:

9-5/8" casing passes 30 MPa external pressure test, suitable for 3,000-meter water depth.

5. Production Process

Material Smelting:

Electric Arc Furnace (EAF) + LF refining, sulfur/phosphorus ≤0.015%;

Continuous casting billet Φ180-400 mm, central segregation ≤Class C 1.0.Hot Rolling:

Three-roll retained mandrel mill, wall thickness uniformity ≤5%;

Online spray cooling, final rolling temperature 900±20°C.Heat Treatment:

Quenching (920°C water cooling) + Tempering (620°C air cooling), hardness 22-32 HRC;

Sour-service pipes use HWQ process, grain size ≥ASTM 7.Quality Inspection:

100% ultrasonic testing (UT) for longitudinal defects (sensitivity Φ1.6 mm flat-bottom hole);

Full-length hydrostatic test (50-100 MPa, holding ≥10 seconds);

Drift test with API drift mandrel (100% pass rate).

6. Case Studies

Middle East Oilfield Project:

Delivered 13-3/8" P110 casing for 4,500-meter well depth, collapse resistance 120 MPa.

7" TP140TT casing supports 30-stage fracturing, boosting single-well output by 25%.

Key Features

J55/P110 Casing: High-strength, corrosion-resistant, compliant with API 5CT.

TP140TT Grade: Optimized for shale gas fracturing with extreme pressure resistance.

Deepwater Compliance: Certified for 3,000-meter offshore operations.

- Q: How are steel pipes used in the manufacturing of wastewater treatment systems?

- Steel pipes are commonly used in the manufacturing of wastewater treatment systems due to their durability, strength, and resistance to corrosion. They are used for various purposes such as transporting wastewater from one unit to another, constructing storage tanks and pipelines, and supporting the infrastructure of the treatment plants. Steel pipes are able to withstand the harsh conditions of wastewater environments, ensuring long-lasting and reliable performance of the treatment systems.

- Q: Can steel pipes be used for underground applications?

- Yes, steel pipes can be used for underground applications. They are commonly used for underground piping systems in various industries such as water, oil, and gas. The durability and strength of steel make it suitable for withstanding underground conditions, providing reliable and long-lasting performance.

- Q: How are steel pipes used in the automotive exhaust systems?

- Steel pipes are commonly used in automotive exhaust systems because steel is a durable and heat-resistant material. Steel pipes are used to transport the exhaust gases from the engine to the muffler and tailpipe, ensuring that the gases are safely and efficiently expelled from the vehicle. These pipes are designed to withstand high temperatures, corrosion, and vibration, making them an essential component in the exhaust system.

- Q: What are the different types of fittings used with steel pipes?

- There are several types of fittings used with steel pipes, including elbow fittings, tee fittings, coupling fittings, union fittings, and flange fittings.

- Q: Can steel pipes be used for underground geothermal systems?

- Yes, steel pipes can be used for underground geothermal systems. Steel pipes are commonly used in geothermal applications due to their durability, strength, and resistance to corrosion. They can withstand high temperatures and pressures associated with geothermal systems, making them suitable for underground installations. Additionally, steel pipes are readily available and cost-effective, making them a popular choice in geothermal projects.

- Q: Can steel pipes be used for conveying solid materials?

- Yes, steel pipes can be used for conveying solid materials. Steel pipes are known for their high strength and durability, making them suitable for transporting solid materials such as ores, grains, or construction materials. They are commonly used in industries such as mining, agriculture, and construction for this purpose.

- Q: Are steel pipes resistant to chemicals and corrosion?

- Yes, steel pipes are generally resistant to chemicals and corrosion.

- Q: Can steel pipes be used for underground sewer lines?

- Yes, steel pipes can be used for underground sewer lines. Steel pipes are commonly used in sewer systems due to their strength, durability, and resistance to corrosion. They are able to withstand the weight of soil and other external pressures, making them suitable for underground applications. Additionally, steel pipes have a long lifespan and can effectively transport wastewater and sewage for many years. However, it is important to ensure that the steel pipes are properly coated or lined to prevent corrosion and extend their lifespan even further.

- Q: 45 and 316 which steel tubes are of high hardness?

- No. 45 steel for high-quality carbon structural steel, the hardness is not high machining, used to make the template, mould studs, guide column, subject to heat treatment. 45 steel quenched and tempered hardness between HRC20~HRC30; 45 steel quenching hardness between HRC55~58, the limit value of up to HRC62.

- Q: Are steel pipes resistant to chemicals?

- Yes, steel pipes are generally resistant to chemicals. They have excellent corrosion resistance properties, making them suitable for transporting various chemicals in industries such as oil and gas, chemical processing, and wastewater treatment. However, the level of resistance can vary depending on the specific type of chemical and the grade of steel used. In some cases, additional protective coatings may be required to enhance chemical resistance.

Send your message to us

7in ExtremeGrip Casing: 10.36mm WT, Fast Ship

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Related keywords