4 X 8 Film Faced Plywood Sheets for Construction Formwork

- Ref Price:

-

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 3000 m³/month

Add to My Favorites

Follow us:

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Specification

Type:

Film Faced Plywood

Application:

For Construction

Packaging & Delivery

| Packaging Details: | Standard Export Packing ; Plywood wrapped in 3mm plywood, tied tightly with steel/plastic strips and edges producted with edge protectors. Plywood on pallets. |

|---|

| Delivery Detail: | 30days after receiving LC or deposit |

|---|

Specifications

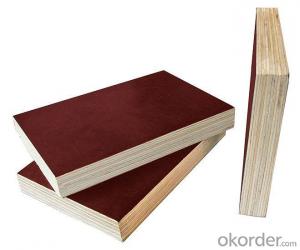

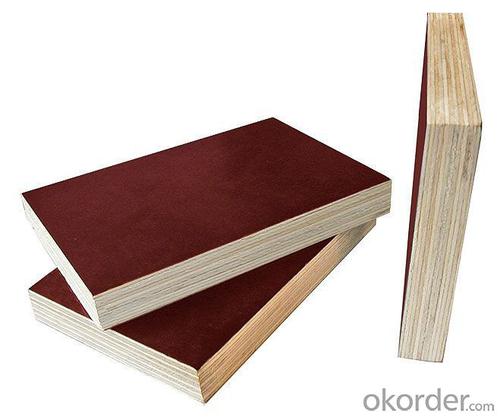

film faced plywood

1)size:1220x2440mm

2)F/B:brown,black,red

3)core:poplar,combi,hardwood

4)glue:WBP,melamine,MR

Product Name | Film faced plywood |

F/B | Black film, brown film, anti-slip film |

Grade | First grade |

Core | Poplar, hardwood, birch, pine, combi , and so on |

Glue | MR WBP |

Thickness | 8-21mm |

Specification | 1220x2440mm, 1250x2500mm, |

Moisture Content | 8-13% |

Package | Standard export package on pallet |

Certification | ISO9001 |

MOQ | 1x40HQ |

Price Terms | FOB, CIF,CNF |

Payment | T/T, 100% irrevocable LC |

Delivery Time | Within 15 days after order confirmed |

Supply Capacity | 3000CBM/month |

Usages | Can be widely used for building concrete, etc |

Remarks | Top class equipment with top class produce techniqueCredit first, fair trading |

No | Property | Unit | Test Standard | Value of Test | Result |

1 | Moisture content | % | EN322 | 8-12 | Check out |

2 | Density | Kg/m3 | EN322 | 560 | Check out |

3 | Bonding quality | Bonding quality | Mpa | EN314 | Max:1.72 Min:0.85 | Check out |

Damage rate | % | GB/T17656-1999 | 60% |

4 | Bending modules of elasticity | Longitudinal | Mpa |

EN310 | 6800 | Check out |

Lateral | 5920 |

5 | Bending strength(N/mm) | Longitudinal | 63 | Check out |

Lateral | 48 |

6 | Cycle Life | About 12-25 repeated using times according projects by formwork application

|

- Q: Plywood in the material defects?

- discoloration discoloration Where the normal color of wood changes called color, can be divided into two kinds of chemical discoloration and fungal discoloration.

- Q: What is the composition of the plywood?

- Plywood usually refers to the plywood or multi-layer board, that is, with the same thickness of two or more layers of veneer plus glue from high temperature suppression

- Q: According to the different composition of the glue, for the construction of plywood with the following types of glue

- High-quality urea-formaldehyde glue / melamine glue / phenolic glue can reach E0 level, E1 level, that can be used directly for indoor

- Q: How do I determine if plywood contains formaldehyde?

- The plywood itself is easy to identify because each side can see the shavings that are pressed together, but it becomes hard to find it after making furniture

- Q: Plywood is generally used in applications where the strength and stability of the material are relatively high

- The birch plywood has a higher hardness and has a higher performance after coating.

- Q: Wood board, plywood, MDF What is the difference

- Blockboard is the core board made of wood board stitching, the two surfaces for the sticky wood veneer solid plate. Veneer, also known as the table, below the board by the board of a board said plate.

- Q: What are the processing defects of plywood?

- Warping warPing is generally a regular deformation, part or all of the surface of the plywood is curved.

- Q: What is the density of plywood?

- Plywood can improve timber utilization and is a major way to save wood

- Q: Class III resistant tide plywood class IV tonic resistant plywood

- It is usually made of odd-numbered veneers and The fibers of the adjacent veneers are perpendicularly bonded to each other

- Q: One of the commonly used materials for furniture is a wood-based panel

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression