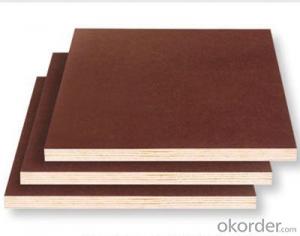

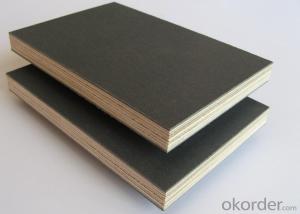

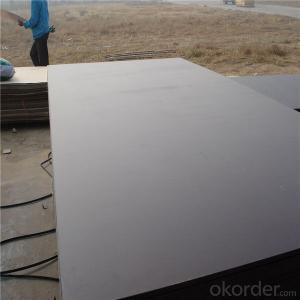

4/3 Brown and Black Film Faced Plywood Shuttering Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m³

- Supply Capability:

- 1000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

Core: Poplar/birch/combi/hardwood core

Glue: WBP/Melamine/MR

Film Color: Dark brown, black film. Other colors, like yellow, green, grey, can be specially ordered.

Thickness : 4 6.5 9 12 15 18 21 24 27 30 mm

Description:

Product Name | Film Faced Plywood | |

Size | 1220*2440MM/1250*2500MM/1500*3000MM or As per customer requested | |

Length(width) tolerance | +/-1mm | Thickness 9-30mm |

Diagonal line | +/-2mm | Thickness tolerance +/-0.5mm |

Film | Black/Brown Film | |

Logo | Logo-Comaccord, Customized logo by customers. | |

Surface | Smooth/wiremeshed(anti-slip) | |

Core material | Materials:Poplar/birch/combi/hardwood(eucalyptus) | |

Glue | WBP(Weather/boil proof)/Melamine/MR | |

Density | 550-700kg/cbm | |

Cycle life | 6-20times | |

Moisture | 6-12% | |

Warpage | <=1% | |

Edge | Sealed with water-proof paint, and different colors are available for us | |

Pallets | Pts/40'GP:16 pallets | Pts/40'HQ:18 pallets |

Veneer layers (longitudinal grain with transverse grain crossed, glue-sprayed among each layers) | 9mm:5 or 7 layers | 12mm:7 or 9 layers |

15mm:9 or 11 layers | 18mm:11 or 13 layers | |

21mm:13 or 15 layers | 25mm:15 or 18 layers | |

Hot press | Only two time hot preseed (Different: two times hot pressed plywood-smooth surface, one time hot pressed-low cost and cheap price), Comaccord only produce high quality product. | |

Capacity | 500-1000m3/day | |

Features:

1) Sizes: 1,220mm x 2,440mm, 1,250mm x 2,500mm,1,200 x 2,400mm

2) Thickness: 9mm, 12mm, 15mm, 18mm, 21mm

3) Core: poplar core, birch core, Hardwood core, combi core

4) Glue: MR glue, WBP glue

5) Film: black color, imported brown film, Chinese brown film

6) It has advantages of smoothness, non-distortion, light weight, high intension and easy application

FAQ:

1)Payment term:T/T deposit,balance against shipping documents,L/C.

2)Samples:free samples as request

3)Quality control:professional QC teams to make sure goods quality

- Q: The difference between the multilayer board and the plywood is as follows

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences

- Q: The structure of the plywood at the same time meet two basic principles

- So the plywood is usually three, five, seven odd level layer. The name of each layer of the plywood is: the surface of the board is called the table, the inner plate is called the core board;

- Q: Plywood is a common material for furniture?

- The usual length and width specifications are: 1220 × 2440mm, while the thickness specifications are generally: 3,5,9,12,15,18 mm and so on. The main tree species are: camphor, willow, poplar, eucalyptus and so on.

- Q: Plywood is generally used in applications where the strength and stability of the material are relatively high

- The birch plywood has a higher hardness and has a higher performance after coating.

- Q: The density of the plywood is greater than that of the same kind of wood

- Plywood gluing strength, according to the Chinese national standards: Ⅰ class plywood for the 1.2 ~ 1.6 MPa, Ⅱ class 1 to 1.4 MPa, Ⅲ class 1 to 1.2 MPa, Ⅳ class 1 MPa

- Q: What is the difference between plywood glue E0E1?

- Melamine gel: moisture-proof, and has a certain resistance to boiling, weather resistance / can be used for outdoor or indoor, but can not often be water immersion.

- Q: What are the defects of the plywood?

- dead dead knots formed by the dead branches of trees, knots surrounded by the surrounding wood together, or even only part of the length of its cross-section of the length of about 1/4 or less than 1/4 , Texture hard or soft, and sometimes fall off the formation of empty.

- Q: Hard fiber board is also a density board

- the same texture direction. Adjacent two-layer veneer grain direction should be the same. The plywood should be the same tree.

- Q: What is medium density fiberboard

- The total thickness of the panel and back panel of the joinery board should be greater than 3 mm, and the panels allow proper patching.

- Q: For the plywood environmental advice?

- Phenolic glue: moisture, excellent resistance to boiling, weather resistance / can be used for outdoor or indoor, can withstand outdoor wind and rain.

Send your message to us

4/3 Brown and Black Film Faced Plywood Shuttering Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m³

- Supply Capability:

- 1000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords