32314 Tapered Roller Bearigs Single Row Bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specificatioin of Taperder Roller Bearings:

The tapered roller bearing is to bear the combination of radial and axial load but mainly afford radial load. The loading capibility is determined by the raceway angle of outer ring, the larger angle afford larger load. This kind of bearings can be seperated and it can be divided into single-row and double-row tapered roller bearings by the number of columns. The clearance for single-row tapered roller bearing should be adjusted by the customers when installation. For the double-row tapered roller bearings,the clearance has already set by the manufacture before ex-factory. Tapered roller bearing has taper shaped inner ring and outer ring raceway,and the roller elements arrange between them. All projection lines from the surface of rollers meet at the same point on bearing axis. This design makes tapered roller bearings particular suitable for combined (axial and radial) loads.The axial loading capacity is determined by the contacting angle α, the bigger angle for α, the larger axial loading capacity is. Tapered roller bearing is usually a seperated bearing, that is,the inner ring assembly including roller and cages, is seperated installed with the cup.

Taper roller bearings are mainly used for radial and axial joint load with radial load as main subject. Axial load capacity relies on raceway angle of outer ring: the bigger the angle is, the bigger the bearing capacity is. Outer ring can be separated and can be easily assembled. During installing and using process, axial clearance and radial clearance and radial clearance can be adjusted and pre-interference installation can be allowed.

Product application:

In many applications tapered roller bearings are used in back-to-back pairs so that axial forces can be supported equally in either direction.

- car and vehicle wheel

- mining equipment

- moderate speed

- engine motors

- axle systems

- construction

- agriculture

- reducers

- gear box

- Q: Why is the cage of tapered roller bearings loose?

- You can come up with the relevant standards, must belong to the bearing standard parts, as long as you meet the standard requirements of the bearing can be spread!

- Q: What are the conditions for the normal and reverse loading of tapered roller bearings?

- 2. anti loaded (outer ring width relative end) horns contact ball bearing or tapered roller bearing pressure center distance is greater than two at the midpoint of the bearing span, known as anti loading, obviously, axial thermal expansion will increase the axial clearance of bearing. In addition, the structure of reverse loading is more complicated, and it is inconvenient to assemble, disassemble and adjust.Stiffness analysis of positive and negative when the transmission parts of cantilever installation, shaft reverse mounting stiffness ratio of forward shafting high, this is because the distance from the center of pressure bearing with large, maximum bending moment of the bearing force, deformation and axial deformation and are less formal.

- Q: What are the E and Y values of the 30209 bearings of tapered roller bearings?

- The shoulder of the positioning shaft is positioned; the transition shaft shoulder is provided for the disassembly of the parts on the shaft or the prevention of the stress concentration. But the axial shoulder will inevitably increase the diameter of the shaft, and the shoulder of the axle will change due to the stress concentration.

- Q: There is a slot in the inner ring of tapered roller bearings, right? Is the roller in the slot?

- There is a slot in the cone... The ball is placed in the slot. Handan, north, LiAskIs there a gap between the roller and the slot?Can I move axially?Chasing the answerThere is a certain clearance between them. It is not very large. It is caused by the force...

- Q: Tapered roller bearing: Bearing expert why burned or locked

- Shaft tolerance is relatively small and fine head, the inner shell inside and nose has obvious signs of friction. If there are traces of friction on one side or on both sides of the inner shell, there is an abnormal contact with the inner shell of the bearing and the friction of the inner shell of the bearing.2, the inner shell shell burning marks are not serious, roller black even deformation, generally is the inner shell or casing tolerance, Ambassador bearing gap smaller, and even negative tolerance caused by burning. Or in the maintenance of the bearing selection is not correct, you can use large clearance bearings.3, the shell burned seriously, the inner shell, roller are no obvious changes, you can observe whether the shell has traces of friction. There are traces of friction on the outside, and it can be considered that the tolerance between the bearing shell and the shaft is insufficient, which results in abnormal friction caused by the slipping of the housing. If there are traces of friction on one side or on both sides of the shell, there is an abnormal contact between the component relative to the bearing housing and the bearing housing, and the heat generated by friction will be burned out.

- Q: What does "tapered roller bearing" suffix "A" mean?

- Tapered roller bearing suffix AA - angular contact ball bearings with a contact angle of 30 degreesA5 - angular contact ball bearings with a contact angle of 25 degrees

- Q: Online cylinder cones are GB/T4663, what do you mean?

- National standard GB 4663-1984, roller bearings, thrust cylindrical roller bearings, size, please check the mechanical design manual (Fifth Edition), second volumes --- commonly used rolling bearings, dimensions and performance parameters / thrust roller bearings.

- Q: that is to say, the taper head is the face and the back is the back

- The bearings do not have to distinguish between the front and back, and there is no positive and negative said, only in accordance with your actual use to identify the installation direction.

- Q: Tapered roller bearings, 70 in diameter, please tell me the model number

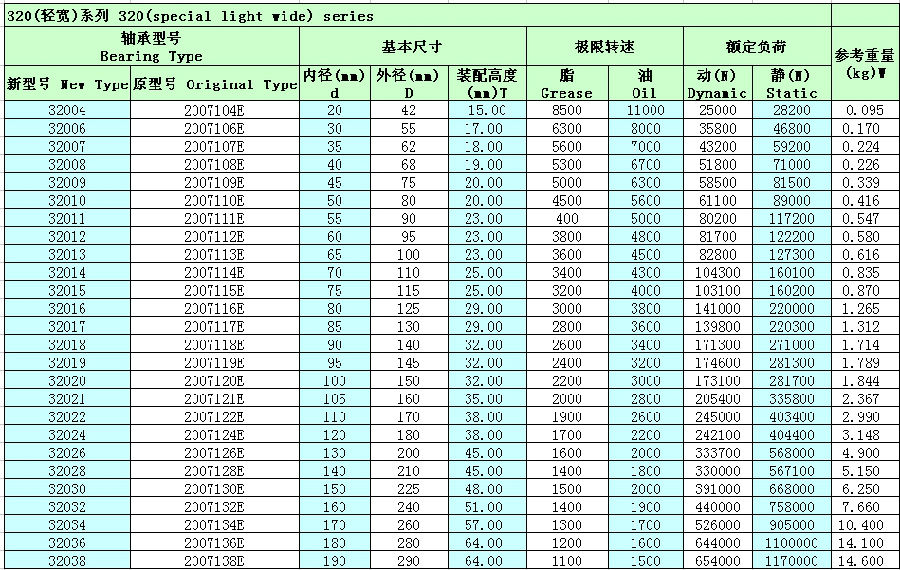

- What about outside diameter (D) and width (B)? You didn't say?.Following are all series of codes and sizes for tapered roller bearings (single column and double row). I hope they can help.Single row tapered roller bearings (taken from GB/T 297-1994)Bearing code |30000: 32914 X2Basic size /mm|d: 70Basic dimensions /mm| D: 100Basic size /mm|T: 20Basic size /mm|B: 19Basic size /mm|C: 16Installation size /mm|da (min):-Installation size /mm|db (max):-Installation dimension /mm| Da (min):-Installation size /mm|Da (max):-Installation size /mm|Db (min):-Installation size /mm|a1 (min): 4Installation size /mm|a2 (min): 6Installation size /mm|ra (max): 1Installation size /mm|rb (max): 1The other is /mm|a size: 19Other sizes /mm|r (min): 1Other sizes /mm|r1 (min): 1The calculated coefficient is |e: 0.33The calculated coefficient is |Y: 1.8The calculated coefficient is |Y0: 1Basic rated load /kN|Cr: 53.2Basic rated load /kN|C0r: 85.5The speed limit / (r/min) | fat: 3600The speed limit / (r/min) | oil: 4500The weight is /kg|W:-

- Q: Turbine turbo rod reduction box, tapered roller bearing at both ends of wormGap measuring method, tapered roller bearingsThe gap is +-0.03, so how do I know the gap is in the range?.

- This should be accomplished by tightening the clearance of the gear box end cover.

Send your message to us

32314 Tapered Roller Bearigs Single Row Bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords