309 Stainless Steel Plate China Mill price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

309 stainless steel plate China Mill price

Product Description

Thickness: 0.3mm-3.0mm (Cold Rolled Stainless Steel Plate)

3mm-100mm (Hot Rolled Stainless Steel Plate)

Width:500mm, 1000mm,1219mm,1250mm,1500mm,

Length: 500mm,2000mm,3000mm,2438mm,as customer requirement

1) Material :

200 Series:201, 202

300 series:301,302,303,304,304L,304H,304N,305,309,309S,310,

310S,316,316L,316Ti,317,317L,321,321H,347M347H

400 series: 408,409,410,416,420,430,436,439,440,441,443,444

600series:610,620,630

900series:904L

Duplex stainless steel :S32750,S31803,S31500,SAF2507,SAF2205,etc

2)Surface Finish: 2B/BA/8K/HL/NO.1/NO.3NO.8/ NO.4/6K/HAIR LINE

3)Standard: GB/T4237-2009

GB/T4238-2009

GB/T3280-2007

GB/T4237-2007

JISG4304-2005

JISG4305-2005

ASTM A240/240M-10

ASTM A240-05

4)Rolling Range: Thickness*Width*Length 0.3-100mm*500-4200mm*500-18000mm or as per your request

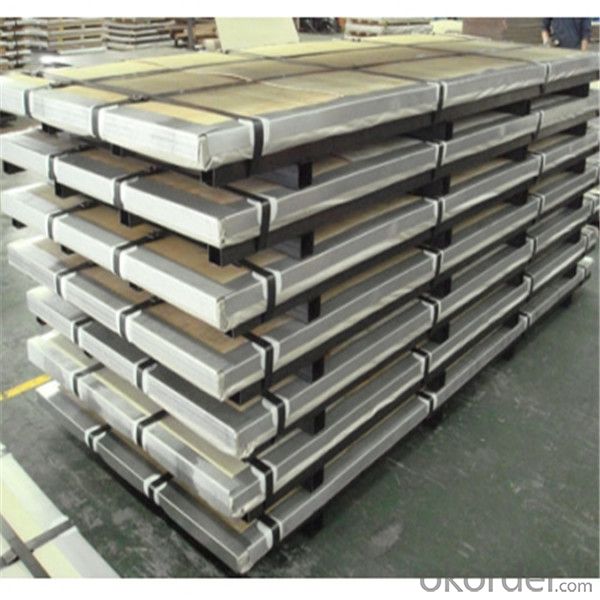

5)Packing: With paper rolled inside and with wooden pallets or PVC coating or customize packing Export standard package in bundled or as required.

Product Uses

Finish | Thickness | Characteristics |

No. 1 | 2.0mm ~12.0mm | Surface finished by hot-rolling, annealing and pickling, characterized by white pickled surface. |

2B | 0.3mm ~3.0mm | Finished by heat treatment, pickling after cold rolling, followed by skin pass line to be brighter. |

BA | 0.3mm ~1.5mm | Processed with bright heat treatment after cold rolling. |

No. 4 | 0.4mm ~3.0mm | Polishing with No. 150 to No.180 abrasives. The most popular finishes. |

HL | 0.4mm ~3.0mm | Finished by continuous polishing streaks by using abrasive of suitable grain size. |

SB | 0.4mm ~3.0mm | Polishing with No. 150 to No. 180 Scotch-Brite abrasives. |

Packaging & Shipping

- Q: Are stainless steel sheets suitable for food processing applications?

- Yes, stainless steel sheets are highly suitable for food processing applications. Stainless steel is known for its excellent corrosion resistance, making it ideal for use in environments that involve exposure to moisture, chemicals, and food substances. It is also non-porous, which means it does not absorb bacteria or other contaminants, making it hygienic and easy to clean. Stainless steel sheets are also heat resistant and can withstand high temperatures, making them suitable for cooking and processing applications. Additionally, stainless steel is durable and long-lasting, ensuring that it can withstand the demands of food processing operations. Overall, stainless steel sheets are a popular choice in the food industry due to their cleanliness, durability, and resistance to corrosion.

- Q: Are stainless steel sheets suitable for chemical transport containers?

- Yes, stainless steel sheets are suitable for chemical transport containers. Stainless steel is highly resistant to corrosion, making it an ideal material for withstanding the potentially corrosive nature of chemicals. It also offers excellent strength and durability, ensuring the safe transportation of chemicals without compromising their integrity. Additionally, stainless steel is easy to clean and maintain, which is crucial for preventing cross-contamination during transportation.

- Q: 904L stainless steel plate generally used in what industry is more?

- Super austenitic stainless steel (904L stainless steel) is a highly alloyed austenitic stainless steel carbon content is very low, in dilute sulphuric acid has good corrosion resistance for corrosion in harsh environmental conditions and design.

- Q: Are stainless steel sheets available in different finishes?

- Yes, stainless steel sheets are available in different finishes.

- Q: Can stainless steel sheets be used for medical implants or devices?

- Yes, stainless steel sheets can be used for medical implants or devices. Stainless steel is a common material used for medical implants and devices due to its excellent corrosion resistance, strength, and biocompatibility. It is often used for applications such as orthopedic implants (like hip replacements and bone plates), surgical instruments, dental implants, and cardiovascular devices. Stainless steel sheets can be precisely fabricated into the desired shape and size for various medical applications, ensuring durability and long-term functionality. Additionally, stainless steel can be easily sterilized, making it suitable for use in medical environments.

- Q: How do I determine the hardness of stainless steel sheets?

- There are various techniques available for determining the hardness of stainless steel sheets. One commonly used method is the Rockwell hardness test, which involves measuring the depth of penetration of an indenter into the material. The Rockwell scale offers different scales for different materials, so it is essential to select the appropriate scale for stainless steel. To conduct the Rockwell hardness test, you will require a Rockwell hardness tester and either a diamond or tungsten carbide indenter. Begin by placing the stainless steel sheet on a stable, flat surface. Next, position the indenter on the surface of the sheet and apply a minor load. Once the minor load is applied, proceed to apply the major load until it reaches its maximum value. After the load has been applied and released, the hardness value will be displayed on the dial or digital display of the Rockwell hardness tester. This value corresponds to a specific hardness scale, such as HRC for stainless steel. It is important to remember that the Rockwell hardness test provides a relative measurement of hardness and may not accurately reflect the physical properties of the material. Moreover, the hardness of stainless steel can vary depending on factors such as alloy composition, heat treatment, and manufacturing process. Therefore, it is advisable to consult the material's specifications or conduct additional tests to obtain a more accurate and comprehensive understanding of the stainless steel sheet's hardness.

- Q: What drill can drill stainless steel?

- Stainless steel is characterized by high toughness and easy sticking. Therefore, the drill hardness is required to be high, the surface finish is better, the drill bit angle is larger than the ordinary bit (130--135 degrees). Cool down at the same time. And the feed amount is greater than 0.15mm, so as not to cut the cold work hardening layer as much as possible. The cutting speed is as low as possible to reduce the cutting temperature. The cutting fluid is concentrated with emulsions. Commonly used processing stainless steel drill bit: high cobalt drill (M35 drill, M42 drill), in which the M42 bit is the best price performance. In addition, carbide drills can be used, but the price is higher.

- Q: Can stainless steel sheets be used for elevator interiors?

- Yes, stainless steel sheets can be used for elevator interiors. Stainless steel is a popular choice for elevator interiors due to its durability, sleek appearance, and resistance to corrosion and wear. It provides a clean and modern look, making it a suitable material for elevators in commercial buildings, hotels, and other high-traffic areas.

- Q: Are stainless steel sheets good for high-temperature applications?

- Yes, stainless steel sheets are excellent for high-temperature applications. Stainless steel has a high melting point, typically ranging from 1400 to 1450 degrees Celsius (2552 to 2642 degrees Fahrenheit), making it suitable for use in environments with elevated temperatures. Additionally, stainless steel exhibits excellent resistance to oxidation at high temperatures, which helps prevent the formation of scales or rust that can weaken the material. It also has good thermal conductivity, allowing for efficient heat transfer. These properties make stainless steel sheets a reliable choice for a wide range of high-temperature applications, including industrial furnaces, heat exchangers, boilers, and exhaust systems.

- Q: Are stainless steel plates 3.4mm or 3.5mm thick?

- There are stainless steel sheets in these two specifications.According to standard GB/T 708-2006 cold rolled steel sheet size tolerances, the stainless steel sheet thickness is 0.3~4 mm,

Send your message to us

309 Stainless Steel Plate China Mill price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords