300KG Flexible Lifting Robot Intelligent Handling Robots Material Handling Equipment

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Easily automate intralogistics for narrow manufacturing spaces with cost-effective solution.

➢ Lifting module raises trolleys, pallets, shelves, and more.

➢ Secure autonomous navigation for safe and effective transport.

➢ Meets industry compliance standards.

300KG Flexible Lifting Robot Intelligent Handling

Full enclosure security enables real-time human-robot collaboration.

Custom audio and lighting for various scenarios with notifications.

Humane emergency stop design and safety bumpers ensure safety in urgent situations.

Concealed debugging panel improves quick troubleshooting convenience.

Stable center of gravity guarantees the safety of the goods during transportation.

Compact but Agile AMR

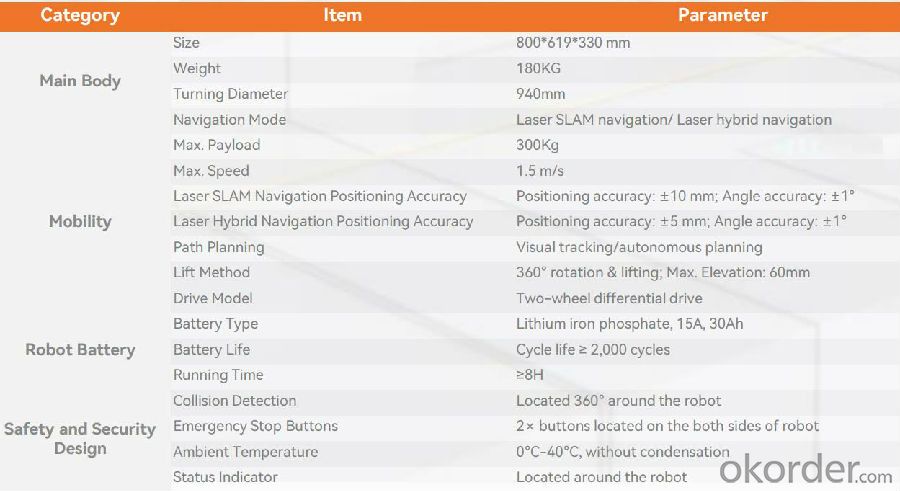

The L300 is a Autonomous Mobile Robot designed to improve internal transportation efficiency in the manufacturing industry. The agile body is equipped with a high capacity 30Ah battery,providing at least 8 hours of uninterrupted operation. This allows for production schedules to be met between shift changes, resulting in virtually uninterrupted production and increased productivity. With the L300, companies can move towards achieving Industry 4.0 and reap the benefits of advanced automation technology.

Flexible Deployment for Quick Start-up

With a highly integrated control system featuring proprietary functionality, the L300 is a top-of-the-line robot. It can achieve a high level of accuracy of ±10mm using only SLAM navigation and ±5mm when combining SLAM and QR navigation. The intelligent control system can also correct for small derailments, while the BMS battery control system enables real-time monitoring of the battery level and automatic charging when necessary. The L300 is a reliable and efficient solution for material handling in manufacturing.

Powerful Rotating Lifting Module

The L300 drive chassis remains the same size even with the integration of the rotary lifting module. The module can handle loads up to 300KG and is calibrated for optimal performance. The integrated control system features a lifting platform posture-follow function, enabling smooth turns and precise placement in tight spaces while maintaining carrier orientation and posture. The module also features a simple and reliable pin design to ensure load stability and prevent falls, as well as a rubber pad on the upper layer to reduce vibration and minimize material damage during handling.

- Q: What is the proof of working in mechanical design?

- Outline first Ⅲ part, is to the qualification examination examination form, time, attention, and the structure of test paper, test question distribution, topic topic quantity, and degree of difficulty of related regulations and instructions.

- Q: Talk about how to cut the cost of moving materials.

- Cost direct costs and indirect costs. Direct costs are inputs and manpower.I hope my answer will help you

- Q: What is the rational and scientific classification of logistics facilities and equipment

- Facilities: like warehouses, roads, public parking lots and so on. Equipment: vehicles, pallets, forklifts, RF scanners, GPS locators, and so on. Large and long-term use and investment, not easy to move and sell are facilities.

- Q: The material needs to be transported, it is easy to produce dust.

- Subjective condition: to the extent that the transport effect is required, such as completely insulating the dust or trying to suppress the dust. What is the company's budget

- Q: The wear-resisting parts in the broken machine are mainly the direct contact with the material

- There are many different types of crusher and different performance. For example: the jaw is broken, the hammer is broken, the fight is broken, the cone is broken... It is. Wear-resisting material is different also, also need according to the material hardness, strength of the material that is broken, the choice is ok. Material: white iron, alloy white iron (high chromium cast iron), high manganese steel, alloy steel (high, medium, low carbon and alloy)... It is. Prices are different because of different materials. Otherwise "overqualified person" not to calculate, "small material big use" not only use not, also do not calculate.

- Q: Why should we emphasize unitization and standardization in material handling

- Unitization is the application of scale thought to different materials. We can simplify the links, save the cost, and realize the overall optimization. To facilitate the mechanization of loading and unloading, reduce the labor intensity and improve the efficiency of the work. Reduce the damage caused by the transformation and improve the quality of logistics.

- Q: Urgent, please go to logistics expert, the question about the warehouse

- Handling activities is the key to the normal logistics activities of each link cohesion, it permeated various fields of logistics and locus of control is to manage store items, reducing attrition rate of goods in the process of handling, loading and unloading time, etc. Yunnan double crane and just ignore it, because of the handling equipment modernization degree is low, only a few small shelves and trolleys, most of the work is still in the artificial give priority to the original state of operation, low working efficiency, and easy damage to the goods. The design of the warehouse is unreasonable, causing long distance movement. Chambers and process chaos, forms the repeated handling, about 70% of the invalid handling, the excessive number of handling, damaged goods, also a waste of time

- Q: Material handling system in the factory

- The machinery factory's internal logistics system involves the production plan, process flow, moving operation, warehouse management, information system and so on.

- Q: There are three things to do when the material is stacked up and down

- Fire proof, waterproof and center of gravity

- Q: What are the requirements for the science of loading and unloading

- Mechanized the moving operation. Provide functions such as production, handling and storage. The various elements of the moving material should be considered when choosing the moving equipment, including the moving and method used. Standardize the type and size of the handling and handling equipment. Adopt methods and equipment that can be adapted to all kinds of work and applications, unless you have to use a special visual device.

Send your message to us

300KG Flexible Lifting Robot Intelligent Handling Robots Material Handling Equipment

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches