3003 Round Aluminium Foil Container For Kitchen Appliance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

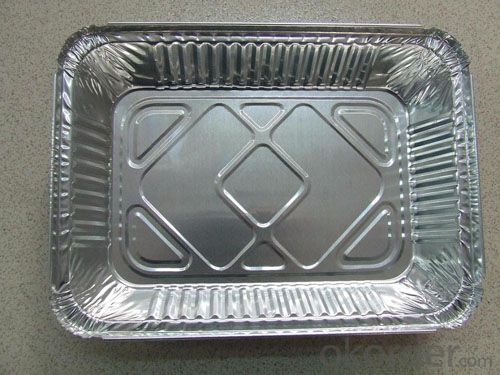

3003 Round Aluminium Foil Container For Kitchen Appliance

Specifications of household aluminum foil container

1Certifications: SGS, ISO9001

2 High grade materials

3 Item No.: AC, AL, AP, AP-PE-PS

4 Top out: 339*223mm-526*327mm

5 Top in: 325*210mm-503*304mm

6 Bottom: 320*200mm-464*264mm

7 Height: 25mm-75mm

8 Capacity: 1600ml-9600ml

9 Thickness: 0.083-0.18mm

10Packing:500pcs-3000pcs

11Carton size: 45.8*34.8*1350px-68*35.8*26CM

12 Shrink wrap with private label we can pack according customer's requirement

Shapes of household aluminum foil container

1 Rectangular container

1) Full-size deep steam table pan

2)1/4 size sheet cake pan

3)1/2 size medium deep steam table pan

4) Standard-compartment vessel

5) Standard-home feeding container

6) Oblong entree

7) Cup muffin pan

8) Baking plate

2 Round container

1) Round deep pie pan

2) Round deep take-out container

3) Serving Trays

4) Oval Roasting pan

5) Round Take-out Container

3 Container lid

1) Container lid

2) Snap-On Plastic Dome Lids

3) Necessary cover

Application of aluminum foil casseroles container

1 Usage:

1) Fast Food

2) Baking

3) Food container

4) Disposable meal box

5) Transporting

6) Freezing

7) Reheating

8) Serving

2 Areas:

1) Supermarket

2) Airline

3) Hotel

4) Restaurant

5) Bakery

Feature of household aluminum foil container

1) Environmental protection

2) Recyclable

3) Variety of designs for size

4) Disposable and use facility

5) Low cost

Packaging of household aluminum foil container

1) No Mark

2) SMC Standard

3) Logo Printed as per customer's request

FAQ

Q: Can we have your catalogue?

A: We can supply partial catalogue. As you know, there are so many different specifications products each item. There are only normal products in the catalogue. We can provide as your requirements.

Q: Could you supply free samples for us?

A: We can supply free samples with you paying shipping cost. We can return you the shipping cost when you have an order.

Q: Can you offer me the price list of your products?

A: We can quote you for our products. Because of so many items and continuous changing price, we can give you price with your products specifications. So you need provide us the products specifications, and we will give you a good price.

Q: What is the MOQ?

A: 2-5 tons

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

- Q: What is the difference between metallized capacitor and metal film capacitor?

- Metallized film capacitor is a metallized film capacitor that is rolled or laminated with a double-sided metallized polypropylene film and a non - metallized polypropylene film

- Q: What is the material of aluminum foil

- The so-called foil is actually very thin aluminum foil.

- Q: Is there any harm to the pure milk packing aluminum foil in boiling water?

- As the soft packaging materials, it is in order for us to buy and carry, and is not used as a heating container, so consumers should Hot Milk when drinking or recommend it from this bag onto the glass, or kitchen use high-temperature beaker, containing the aluminum foil packaging milk is absolutely not to heating with microwave oven. In addition, over heating milk also has an impact on nutrition.

- Q: Are aluminum foil lunch boxes much used in the country?

- In Europe, America, the Middle East, including the present middle east. Plastic tableware is gradually being replaced by aluminum foil products. However, in the context of growing concern about environmental protection, this lunch box has developed rapidly in recent years, and many enterprises have begun to seize the market, and the future prospect is vast.

- Q: How aseptic packaging aluminum foil bags?

- Foil bag has many advantages over other traditional packaging materials (such as difficult to have superior performance, molding, convenient use, low cost, etc.) as one of the plastic packaging materials, which plays a great role in the development of aluminum foil bag, along with other traditional packaging materials incomparable speed.

- Q: What are the specifications and uses of common aluminum foil?

- Soft Packing FoilAlloy status: 8079-O, 1235-OTypical thickness: 0.006 ~ 0.009Processing: composite paper, plastic film, embossing, color, printing and so onEnd use: Confectionery, milk and dairy products, powder foods, beverages, teas, breads and various small foods

- Q: What can be used to make foil?

- Flexible package is a kind of bag container made of soft composite packing material. The flexible package not only has the function of moisture-proof and preservation, but also can print various patterns and characters. It is an ideal material for modern commercial packaging. With the improvement of people's living standard, there is still a lot of room for the development of flexible packaging aluminum foil.

- Q: How can I use aluminum foil for microwave oven?

- When microwave oven uses microwave gear, it is not allowed to have any metal substance in the container. Otherwise, a work will start the internal ignition and damage the microwave headIf you want to use the microwave oven barbecue, mini baking sheet, please use the light wave heating (remember). Aluminum foil is used to wrap the barbecue items. (such as Roast Chicken, wrapped in foil to prevent chicken barbecue when oil splash, cause it is difficult to clean the microwave oven, and can prevent the burned chicken)

- Q: Dcgy-500 type aluminum foil sealing machine is out of order, it is not sealed, burned out which element, how to fix?

- Recommend a small number of products, practical handheld aluminum foil sealing machine. It is the first choice for small businesses to save equipment costs. This machine can adjust sealing power according to sealing size. The bottle neck can be used between 20 and 100 millimeters in diameterHandheld aluminum foil sealing machine use environment:Handheld foil sealing machine maximum ambient temperature 45 degrees centigrade, relative humidity not higher than 80%, the machine should be placed in a well ventilated environment, cooling hole induction power supply side and bottom heat radiating holes and inductive head to ensure clean and smooth. Excessive temperature or humidity will have a great impact on the life of electronic components, and even lead to damage to the equipment.

- Q: Where is the use of high pressure etching into electronic aluminium foil?

- In the family of electrolytic capacitors, aluminum electrolytic capacitors are widely used in the world for nearly 20 years because of their high performance, low cost and wide range of uses. Taking Japan as an example, the output of electrolytic capacitor foil was about 3000 tons in 1995. By 2001, the output has reached 70 thousand to 80 thousand tons, almost increasing at an alarming rate.

Send your message to us

3003 Round Aluminium Foil Container For Kitchen Appliance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords