3003 H14 H24 Aluminum Strip for Hollow Glass Strip Factory Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

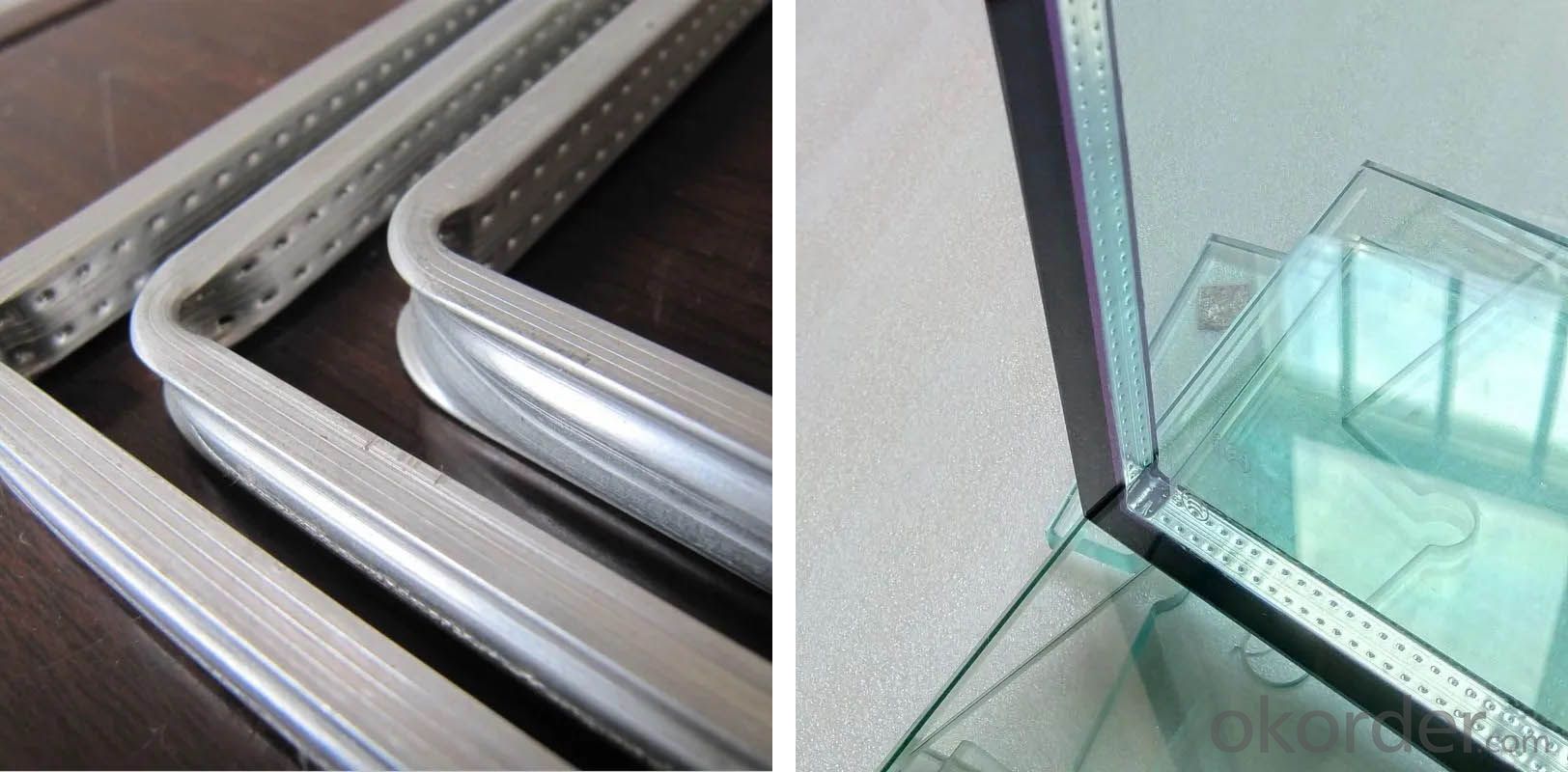

Hollow glass aluminum strip is used for hollow glass strip spacers. The commonly used material is 3003 aluminum alloy. Its quality is directly related to the use effect, service life and thermal insulation function of hollow glass. Its main function is to evenly separate the two sides or multiple pieces of glass in the hollow glass and effectively support it.

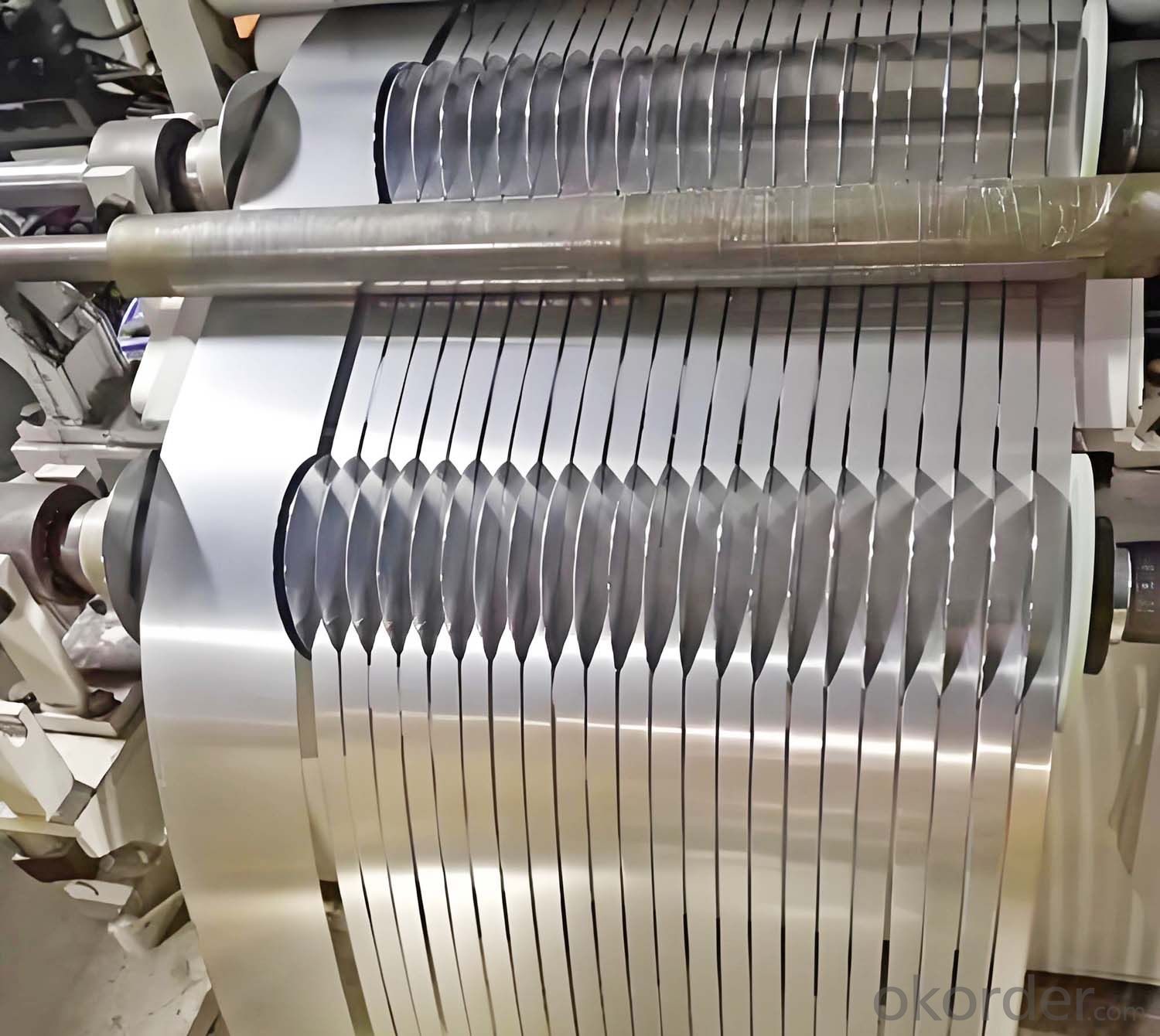

Hollow glass strips are aluminum products made of high-purity aluminum as raw materials. After dozens of process treatments, the surface is flat and smooth, non-oxidizing, non-corrosive, and has no effect on desiccant. It effectively eliminates the phenomenon of atomization. It is a new type of environmentally friendly building material product with a broad application market. The surface of 3003 alloy aluminum strip is flat and smooth, rust-proof, and corrosion-resistant with high brightness; the surface of the aluminum strip is evenly permeable, with good straightness, no deformation, and stable size; it has high strength and good toughness, and can be continuously bent into aluminum frames of any angle with bending equipment.

Advantages of 3003 aluminum strip for hollow glass strips:

1. Excellent corrosion resistance: stable performance in humid environment, not easy to rust.

2. Good processing performance: easy to process and shape, maintain strength and toughness, not easy to crack.

3. Lightweight characteristics: reduce the weight of finished glass, reduce transportation and installation costs.

4. Good thermal conductivity: improve thermal insulation performance and enhance energy saving effect.

5. Strong antioxidant performance: maintain long-term beauty and functionality.

6. Strong adaptability to surface treatment: various surface treatments can be performed to improve corrosion resistance and aesthetics.

7. High cost performance: low cost, superior performance, an economical choice.

8. Environmental protection and recyclable: aluminum can be fully recycled, in line with the concept of green building and sustainable development.

Specifications:

| Alloy | 3003 |

| Temper | H14 H24 H16 etc |

| Thickness | 0.25-0.4mm |

| Diameter | 100-260mm |

| Surface treatment | painting, anodizing |

| Technology | cold rolling |

| Color | silver, black |

| Application | hollow glass, hollow door, train, bus |

| Features |

|

| MOQ | 1-3 tons |

3003 aluminum alloy chemical composition (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.05 | 0.15 | remainder |

Application fields

1. Hollow glass strips: widely used in building doors and windows, glass curtain walls, energy-saving glass and other structures.

2. Other related fields: in some cases, it can also be used for insulation and sealing components that require lightweight and corrosion-resistant materials.

FAQ:

Q1: How to ensure quality?

A1: Factory test certification is provided with shipment, and third-party inspection can be provided

Q2. What are the main products of your company?

A2: Our main products are aluminum, aluminum plate, aluminum foil, aluminum strip, patterned plate, automotive plate, marine grade aluminum plate, household foil, hydrophilic aluminum foil, bottle cap material, etc.

Q3: Where is your factory?

A3: Our company's processing center is located in Xin'an Industrial Assemble Region, Luoyang, Henan Province, China

Q4: What are the advantages of your company?

A4: We have many professionals, technicians, more competitive prices and best after-sales service than other companies.

- Q: Is it possible to incorporate recycled materials into construction, specifically using aluminum strips for roofing?

- <p>Yes, you can use recycled materials in building construction. Aluminum strips are often made from recycled aluminum, which is a sustainable choice. Recycled aluminum requires significantly less energy to produce compared to new aluminum, reducing environmental impact. It's important to ensure that the recycled materials meet quality standards for construction and are sourced responsibly. Using recycled aluminum for roofing can contribute to a greener building project and help in waste reduction.</p>

- Q: Is it possible to utilize aluminum strips in a construction project focused on sustainability and environmental responsibility?

- <p>Yes, you can use aluminum strips for a green building project. Aluminum is a versatile and sustainable material due to its recyclability and low energy consumption in production. It also has a high strength-to-weight ratio, which can contribute to the energy efficiency of a building. However, it's important to consider the source of the aluminum and ensure it is produced with minimal environmental impact. Using recycled aluminum can further enhance the green credentials of your project.</p>

- Q: Is it possible to use aluminum strips as a material for fencing?

- <p>Yes, you can use aluminum strips for fencing. Aluminum is a popular choice due to its durability, resistance to corrosion, and low maintenance requirements. It is lightweight, easy to install, and can be shaped into various designs. Aluminum fencing is also known for its strength and can be an effective barrier for security purposes. However, it may not be suitable for all environments, especially where high wind loads or heavy impacts are expected, as it can dent or bend more easily than some other materials.</p>

- Q: Is it possible to apply paint to aluminum strips?

- <p>Yes, aluminum strips can be painted. However, proper surface preparation is crucial for good adhesion and durability of the paint. This typically involves cleaning the aluminum to remove any grease or contaminants, followed by etching or using a primer designed for aluminum to promote better paint adherence. After priming, the aluminum can be painted with a suitable paint, such as acrylic or epoxy, which are known for their compatibility with metal surfaces. It's important to follow the manufacturer's instructions for the specific paint and primer used to ensure the best results.</p>

- Q: Is it possible to substitute aluminum strips with other metal sheets in construction projects?

- <p>Yes, you can use different types of metal sheets in place of aluminum strips in your construction projects, depending on the specific requirements. Metals like steel, stainless steel, and copper can be used as alternatives. Each metal has unique properties such as strength, weight, corrosion resistance, and thermal conductivity, which can affect the project's performance and longevity. It's crucial to consider the environmental conditions, load-bearing requirements, and cost implications when choosing an alternative to aluminum. Always consult with a structural engineer or a material expert to ensure the chosen metal meets the project's needs.</p>

- Q: This question asks about the impact of aluminum strips on the performance of vehicles. It seeks to understand how these strips influence the vehicle's operation and efficiency.

- <p>Aluminum strips can affect vehicle performance in several ways. They are often used in the construction of lightweight vehicles to enhance fuel efficiency by reducing overall weight. Aluminum's high strength-to-weight ratio makes it ideal for vehicle components, improving structural integrity without adding excessive weight. Additionally, aluminum strips can be used in heat exchangers for cooling systems, which can improve engine performance by maintaining optimal operating temperatures. However, the use of aluminum strips must be balanced with considerations of cost, corrosion resistance, and recycling potential, as these factors can also influence vehicle performance and lifecycle costs.</p>

- Q: Which brand of aluminium band for dry transformer?

- The domestic brand is 1060, and the state is soft. Suitable for winding.

- Q: Explain how aluminum strips play a role in enhancing energy efficiency.

- <p>Aluminum strips contribute to energy efficiency primarily through their use in thermal insulation and reflective properties. In building construction, aluminum strips can be used to create airtight seals around windows and doors, reducing heat transfer and drafts, which in turn lowers the need for heating or cooling systems. Additionally, aluminum's reflective nature can be utilized in radiant barriers, which reflect heat away from buildings, reducing the energy required for cooling. In electrical applications, aluminum strips are used in high-efficiency transformers and electrical conductors due to their high conductivity and light weight, reducing energy loss during transmission. Overall, aluminum strips enhance energy efficiency by minimizing heat loss and improving the performance of energy systems.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of using aluminum strips as a roofing material.

- <p>Aluminum strips for roofing offer several advantages, including durability, resistance to corrosion and rust, and low maintenance requirements. They are lightweight, which reduces the load on the structure, and can be easily recycled. Additionally, aluminum strips can be coated with various finishes to match architectural styles, enhancing aesthetic appeal. However, they also have some disadvantages, such as being more expensive than traditional materials like asphalt shingles. They can also be noisy during rain and hail, and may require professional installation due to their specialized nature.</p>

- Q: What characteristics of aluminum strips make them an ideal material for roofing purposes?

- <p>Aluminum strips are suitable for roofing due to their lightweight nature, which reduces structural load. They offer excellent corrosion resistance, protecting against rust and decay, and are highly durable, maintaining their integrity for decades. Aluminum's malleability allows for easy shaping into various profiles, enhancing design flexibility. Additionally, aluminum strips reflect heat well, reducing energy consumption for cooling, and they are recyclable, contributing to environmental sustainability.</p>

Send your message to us

3003 H14 H24 Aluminum Strip for Hollow Glass Strip Factory Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Related keywords