2x4 Linyi Construction Timber PP Plastic Plywood for Concrete Formwork

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Type: | Plywoods | Place of Origin: | Shandong China (Mainland) | Brand Name: | FANGYUAN brand |

Model Number: | plastic coated plywood | Usage: | Outdoor | Grade: | First-Class |

Main Material: | Poplar | Formaldehyde Emission Standards: | E1 | Plywood Type: | 15-Ply Boards |

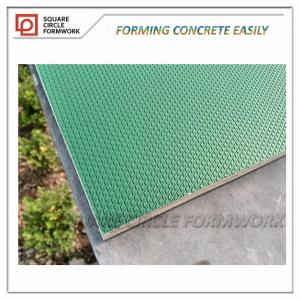

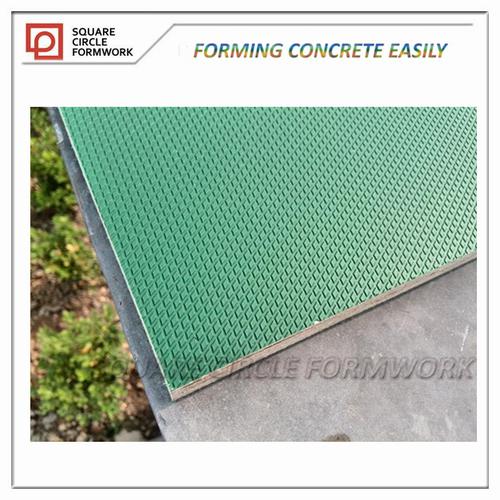

Surface: | PP plastic | Based board: | poplar, birch | Glue: | WBP phenolic, 72h water boiling |

Reusability: | 30 times at least | Dismantling: | no release agent | Cleaning: | easy cleaning by water, no oil treatment |

Concrete finish: | nice finish without re-work again | Color: | green, red, blue, grey, on request |

Packaging & Delivery

Packaging Detail: | standard seaworthy export package, inner packing by waterproof plastic bag and hard corrugated paper, outside packing by plywood pallet and fastened by steel belts |

Delivery Detail: | within 20 days from the date we receive the deposit |

Specifications

plastic coated plywood

1.coating by PP plastic

2.WBP phenolic

3.reusable 30 times at least

4.nice concrete finish

Product Description

Structure

Specification

Advantages

Technical test

Handling instruction

Comparasion

Packaging & Shipping

Our Services

1. Pengcheng Group have been specializing production andexport plywood for over 20 years, supplying highquality construction plywood for oversea customers.

2. Independent laboratary test the essential technicaldates of construction plywood, such as

bonding strength, moisture, bendingstrength, and bending modules of elasticity.

3. The CE and ISO9001 certifications are available.

4. well-built operation process for inspection, clearancecustoms, necessay export documents,

and logistics.

Company Information

Production capability

Company profile

FAQ

1. Are you a manufacturer or trader ?

Pengcheng Group have 3 factories and 1trading company, specializing in direct-sales.

2. How do you guarantee the quality of product ?

Firstly, Pengcheng Group have independentQC department to check and test every

production process. Meanwhile, we havebuilt files to resource the product when it meets

problems.

Secondly, our product have been tested byNational Building Materials Testing Center and

European Laboratory.

Finally, we supply free samples for test.

3. How is your price ?

Pengcheng Group is located in Linyicity, the largest plywood base in China. We have built

good supply chain of raw materials.Besides, the strict management system can control the

cost for every production and sales.

4. How do we build a long-standing business ?

Firstly, we supply good product withreasonable price.

Secondly, when we have reached anagreement for long-standing business, the best payment

terms are considerate.

Thirdly,expanding the sales chanels by cooperation, such as attending the internationalfairs,

building factory in your country.

Finally, invest the new project and buildthe international joint-venture company.

- Q: National standards for decorative veneer veneer plywood performance requirements

- GB 18580-2001 "interior decoration materials, wood-based panels and their products in the formaldehyde release limit" also provides the product of formaldehyde emission limit.

- Q: defects are divided into four grades

- The above four levels of the panel should be sand (scrap) light, special needs can not sand (scrap) light or two sand (scrap) light.

- Q: Judging wood is the standard for plywood

- For example, an old dresser may seem dilapidated, but maybe it is still hard to find now good wood to do it. In this article, we will explain to you how to identify a piece of furniture, and to ...

- Q: Multilayer board and plywood difference

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q: Wood board, plywood, MDF What is the difference

- Can be single-sided sanding, double-sided sanding or both sides are not sanding.

- Q: What are the key points for plywood selection?

- The interior of the building with plywood, should be consistent with GB50222 "building interior decoration design fire safety regulations" requirement

- Q: Ordinary plywood is divided into four categories

- Thickness specifications for the 6,9,12,15,18 and so on. The main performance indicators for the water content of 4 to 13%, the expansion of water thickness ≤ 12%, as well as tensile strength, bending strength, grip nail force.

- Q: Plywood quality requirements include appearance level, size, physical and mechanical properties of the three elements.

- Ordinary plywood size: plywood thickness of 2.7mm, 3.3mm, 4.5mm, 5.5mm, 6mm ... ... since 6mm, according to lmm increase

- Q: For the plywood environmental advice?

- E0 is the highest environmental rating. E1 grade glue to do the plywood can be used directly for the interior.

- Q: The basic principle of plywood

- First, symmetry; Second, adjacent layers of single-board fiber perpendicular to each other

Send your message to us

2x4 Linyi Construction Timber PP Plastic Plywood for Concrete Formwork

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords