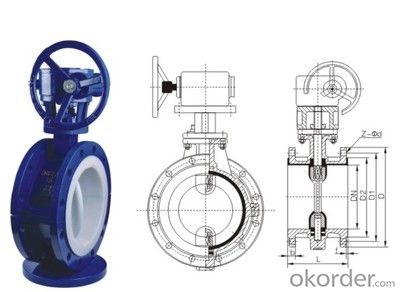

2inch Worm gear operated PTFE seated wafer type DI plated butterfly valves

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Technical data

Nominal diameter | DN(mm) | 40-600 | |

Nominal pressure | PN(mpa) | 1.0 | 1.6 |

Test pressure(Mpa) | Shell test | 1.5 | 2.4 |

Test pressure(Mpa) | Seal test | 1.1 | 1.76 |

Appropriate medium | Air,water,sewage,steam,coal gas,oil | ||

Drive modality | Handle,worm gear box, penumatic drive,electric drive | ||

Material for main parts

Parts name | Material |

Body | Ductile cast iron,cast steel,Alloy steel, stainless steel |

Disc | Grey cast iron,ductile cast steel,cast steel,stainless steel and hoc material |

Seal ring | Manifold rubber,such as EPDM, PTFE,NBR,Viton,CR |

Stem | steel,ss420,ss304,ss316 |

Packing | O-ring,flexible graphite |

Butterfly valve seal material choice and apporpriate tempersture

Material variety | Neoprene | Styene rubber | EPDM | PTFE | Silicon rubber | Fluorine rubber |

Resistance highest temperature | 82°C | 93°C | 150°C | 232°C | 250°C

| 204°C |

Resistance lowest temperature | -40°C | -40°C | -40°C | -268°C | -70°C | -23°C |

Suitable working temperature | ≤65°C | ≤80°C | ≤120°C | ≤200°C | ≤200°C | ≤180°C |

Name | Material |

Body | ductile cast iron, WCB, stainless steel |

Disc | ductile cast iron, WCB stainless steel, Al-bronze |

Stem | SS420, SS431 or as request |

Disc seat ring | EPDM |

Body seat ring | SS304 |

Retainer | SS304 |

Shaft bearing | Al-bronze, self-lubricating bearing |

Bolt & nuts | SS304 |

Coating | epoxy coating, thickness: min. 250 microns, color code: RAl5015, 5017, 5010, and etc. |

China National Building Materials Group Corporation (CNBM) was established in 1984 with approval from the State Council, and then became a Central Enterprise under direct supervision of State-owned Assets Supervision and Administration Commission of the State Council in 2003.

Upholding the philosophy of “Making Best Use of Resources to Serve Construction”, and vigorously carrying out such strategies as “technical innovation”, “internationalization of building materials”, and “building strength with talents”, CNBM is the largest comprehensive building materials industry group in China that integrates scientific research, manufacturing and logistics into one entity, and consists of four business platforms, i.e. industry, technology, complete set of equipment, and trading & logistics. As of the end of 2009, CNBM’s total assets exceeded RMB 110 billion, with 100,000 employees, and 20 companies under direct management with 100% share control or majority control, among which 6 were listed companies, including 2 overseas listed.

CNBM practices the parent-subsidiary management system, and is one of those wholly state-owned enterprises carrying out the pilot trial of Board of Directors system and innovation system. As the strategic center, decision center, resources center, and policy & culture center, our Group exercises its right as a contributor. Whereas, our sub-groups functioning as business platforms, are mandated to construct the profit center based on their core competences to enlarge brand awareness and increase market share.

- Q: What are the different grades of steel and their respective applications?

- There are several grades of steel, each with unique properties and applications. Some common grades include carbon steel, which is widely used in construction and manufacturing; stainless steel, which is resistant to corrosion and commonly used in kitchen appliances and medical equipment; tool steel, which is known for its high hardness and used in cutting tools; and alloy steel, which contains different elements to enhance specific properties and is used in automotive and aerospace industries.

- Q: How is steel used in the manufacturing of oil and gas pipelines?

- Steel is commonly used in the manufacturing of oil and gas pipelines due to its strength, durability, and resistance to corrosion. It is used to construct the main body of the pipelines, providing structural integrity and the ability to withstand high-pressure environments. Additionally, steel pipes can be welded together to create long, continuous pipeline networks, ensuring the efficient transportation of oil and gas over long distances.

- Q: What are the different types of steel profiles used in architecture?

- There are several types of steel profiles commonly used in architecture, including I-beams, H-beams, C-channels, angle irons, and hollow structural sections (HSS). These profiles offer different structural properties and are utilized for various purposes, such as providing support, creating framework, and enhancing aesthetic design in architectural structures.

- Q: How do steel products contribute to the transportation and logistics sector?

- Steel products contribute to the transportation and logistics sector in multiple ways. Firstly, steel is used extensively in the manufacturing of vehicles, including cars, trucks, trains, and ships. Its high strength-to-weight ratio and durability make it an ideal material for constructing vehicle bodies, chassis, and components, ensuring safety and reliability in transportation. Moreover, steel is crucial in the construction of infrastructure necessary for transportation and logistics, such as bridges, tunnels, railway tracks, and port facilities. These structures require the strength and resilience of steel to handle heavy loads, withstand harsh environmental conditions, and provide efficient and safe transport routes. Additionally, steel plays a significant role in the production of shipping containers, which are essential for the movement and storage of goods globally. These containers are made from steel to withstand stacking, handling, and transportation while protecting the goods inside. Steel's strength and corrosion resistance make it an ideal material for these purposes. Overall, the use of steel products in the transportation and logistics sector ensures the efficiency, reliability, and safety of various modes of transportation, infrastructure, and storage, contributing to the smooth functioning of global supply chains and facilitating economic growth.

- Q: What are the advantages of using steel wire ropes?

- There are several advantages of using steel wire ropes. Firstly, they have high strength and durability, making them suitable for heavy-duty applications. They can withstand high loads and are resistant to wear and tear. Secondly, steel wire ropes have excellent flexibility, allowing them to be easily bent and coiled without compromising their strength. This makes them ideal for use in various industries, such as construction, mining, and maritime. Additionally, steel wire ropes have good resistance to corrosion and extreme temperatures, ensuring longevity and reliability.

- Q: How is steel used in the construction of sports stadiums and arenas?

- Steel is used extensively in the construction of sports stadiums and arenas due to its strength, durability, and versatility. It is used to create the framework and support structure of the building, including the roof, columns, beams, and trusses. Steel allows for large, open spaces without the need for excessive support columns, providing unobstructed views for spectators. Additionally, steel is used in the construction of seating areas, staircases, and walkways, ensuring safety and stability. Overall, steel plays a crucial role in creating the impressive and functional structures necessary for modern sports venues.

- Q: How is steel used in the construction of wastewater treatment plants?

- Steel is extensively used in the construction of wastewater treatment plants due to its durability, strength, and corrosion resistance. It is used for various applications such as structural supports, tanks, pipes, and equipment. The steel structures can withstand the harsh environment and chemicals found in wastewater, ensuring the longevity and reliability of the treatment plant.

- Q: What are the different types of steel products used in the manufacturing of gardening tools?

- There are various types of steel products used in the manufacturing of gardening tools, including stainless steel, carbon steel, and alloy steel. Stainless steel is popular due to its resistance to corrosion and rust, making it ideal for tools exposed to moisture. Carbon steel is durable and can be heat-treated for added strength, commonly used for blades and pruning tools. Alloy steel, a blend of different metals, offers a combination of strength, durability, and resistance to wear and tear, making it suitable for heavy-duty gardening tools.

- Q: What are the applications of steel plates?

- Steel plates have a wide range of applications across various industries such as construction, automotive, manufacturing, and shipbuilding. They are commonly used as structural elements in buildings, bridges, and infrastructure projects. Steel plates are also utilized in the production of machinery, equipment, and vehicles due to their strength, durability, and versatility. Additionally, they find applications in the energy sector for the construction of power plants and pipelines.

- Q: What are the properties and characteristics of stainless steel?

- Stainless steel is a versatile and durable material known for its excellent corrosion resistance. It contains a minimum of 10.5% chromium, which forms a thin, protective oxide layer on its surface, preventing rust and staining. This oxide layer is self-repairing, which helps maintain the material's integrity over time. Some key properties of stainless steel include its high strength, heat resistance, and low maintenance requirements. It is also non-magnetic and has good formability, making it suitable for various applications. Stainless steel is available in different grades, each with specific compositions and properties tailored for different uses, such as food processing, construction, automotive, and medical equipment. Overall, its combination of strength, corrosion resistance, and versatility makes stainless steel a widely used and sought-after material in many industries.

Send your message to us

2inch Worm gear operated PTFE seated wafer type DI plated butterfly valves

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords