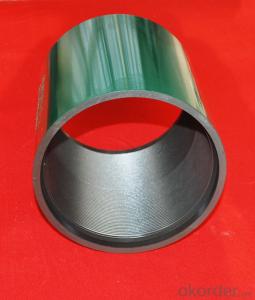

13 3/8" 54.5ppf API 5CT casing pipe BTC end

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

1.API casing pipe

2.K55 or J55 or others

3.API standard

4.STC thread or others

5. Any OD and wall thickness you need.

Casing Technical Specification (Standard API Spec 5 CT) | |||||||

Size | Outside Diameter | Inside Diameter | Grade | Wall Thickness | |||

in | mm | in | mm | in | mm | ||

4-1/2 | 4.500 | 114.30 | 4.000 | 101.60 | J55K55N80 | 0.250 | 6.35 |

3.920 | 99.57 | J55K55N80 | 0.290 | 7.37 | |||

5 | 5.000 | 127.00 | 4.408 | 111.96 | J55K55N80 | 0.296 | 7.52 |

4.276 | 108.61 | N80P110 | 0.362 | 9.29 | |||

4.126 | 104.80 | N80P110 | 0.437 | 11.10 | |||

5-1/2 | 5.500 | 139.70 | 4.892 | 124.26 | J55K55N80 | 0.304 | 7.72 |

4.778 | 121.36 | N80 | 0.361 | 9.17 | |||

4.670 | 118.62 | N80 | 0.415 | 10.54 | |||

7 | 7.000 | 177.80 | 6.366 | 161.70 | J55K55N80 | 0.317 | 8.05 |

6.276 | 159.41 | J55K55N80 | 0.362 | 9.19 | |||

6.184 | 157.07 | N80 | 0.408 | 10.36 | |||

9-5/8 | 9.625 | 244.48 | 8.755 | 222.38 | N80 | 0.435 | 11.05 |

8.681 | 222.50 | N80 | 0.472 | 11.99 | |||

10-3/4 | 10.750 | 273.05 | 10.050 | 255.27 | H40J55K55N80 | 0.350 | 8.89 |

9.850 | 250.19 | J55K55N80 | 0.450 | 11.43 | |||

13-3/8 | 13.375 | 339.72 | 12.615 | 320.42 | J55K55 | 0.380 | 9.65 |

12.415 | 315.34 | J55K55N80 | 0.480 | 12 | |||

- Q: Can steel pipes be used for underground stormwater drainage?

- Yes, steel pipes can be used for underground stormwater drainage. Steel pipes are commonly used in underground drainage systems due to their durability, strength, and resistance to corrosion. They can effectively manage the flow of stormwater and provide long-lasting solutions for underground drainage needs.

- Q: Are steel pipes suitable for wastewater treatment facilities?

- Steel pipes are indeed a suitable option for wastewater treatment facilities. These facilities commonly employ steel pipes because of their impressive strength, durability, and resistance against corrosion. Given that wastewater treatment facilities often deal with corrosive and abrasive substances, steel pipes have the ability to endure these harsh conditions. Furthermore, steel pipes come in various sizes and configurations, allowing for effortless installation and customization to meet the specific requirements of the facility. Moreover, if necessary, steel pipes can be easily repaired or replaced, ensuring the long-lasting and dependable nature of the wastewater treatment system. Ultimately, steel pipes are an appropriate choice for wastewater treatment facilities due to their strength, durability, corrosion resistance, and flexibility for installation and maintenance.

- Q: What are the advantages of using steel pipes over other materials?

- There are several advantages of using steel pipes over other materials: 1. Strength and Durability: Steel pipes are known for their exceptional strength and durability. They can withstand high pressure, heavy loads, and extreme weather conditions, making them suitable for various applications, including transportation of fluids and gases, structural support, and underground pipelines. 2. Corrosion Resistance: Steel pipes can be coated with different materials to enhance their resistance to corrosion. This makes them suitable for transporting water, chemicals, and other corrosive substances without the risk of pipe degradation. Additionally, steel pipes are less susceptible to rust, which prolongs their lifespan. 3. Cost-effectiveness: Although steel pipes may have a higher upfront cost compared to other materials, they offer long-term cost-effectiveness. Due to their durability and resistance to corrosion, steel pipes require less maintenance and replacement, resulting in reduced operational costs over time. 4. Versatility: Steel pipes come in various sizes, shapes, and thicknesses, making them versatile for different applications. They can be easily customized and fabricated to meet specific requirements, such as bending, welding, and threading. 5. Fire Resistance: Steel pipes have a high melting point, making them resistant to fire and reducing the risk of structural damage during a fire incident. This characteristic is particularly important in industries where fire safety is crucial, such as oil and gas, chemical, and construction. 6. Eco-friendly: Steel is a recyclable material, and steel pipes can be recycled and reused multiple times without compromising their quality. This not only reduces the demand for new materials but also contributes to environmental sustainability. 7. Excellent Flow Characteristics: Steel pipes provide smooth internal surfaces, minimizing friction and allowing for efficient flow of fluids and gases. This advantage is particularly significant in industries where fluid dynamics and energy efficiency are essential, such as oil and gas, water supply, and HVAC systems. In conclusion, steel pipes offer numerous advantages over other materials, including strength, durability, corrosion resistance, cost-effectiveness, versatility, fire resistance, eco-friendliness, and excellent flow characteristics. These advantages make steel pipes the preferred choice for a wide range of applications in various industries.

- Q: How do you solder purple copper plate and steel tube?

- When the copper pipe and the size is not too large, such as 10 mm below the pipe welding, brazing is suggested, with brass solder, such as Wei Odin 201 solder, with supporting solder paste, with a neutral flame welding, the copper plate is heated to about 800 degrees, and then use the solder with 201 Wei Odin 201-F in solder welding, welding wire with melt molding.

- Q: Can steel pipes be used for underground culverts?

- Indeed, underground culverts can utilize steel pipes. Renowned for their robustness, longevity, and ability to withstand diverse environmental influences, steel pipes are ideal for subterranean applications. They exhibit exceptional resilience to substantial burdens, intense hydrostatic pressure, and the erosive impact of soil and water. Moreover, steel pipes offer a range of dimensions and thicknesses, enabling customization to meet precise project prerequisites. Nevertheless, prudent consideration must be given to variables such as soil attributes, water table elevations, and the likelihood of corrosion during the selection of the most fitting steel variant and protective coatings for the pipes.

- Q: What is the difference between steel pipes and cast iron pipes?

- The main difference between steel pipes and cast iron pipes is the material they are made of. Steel pipes are made from an alloy of iron and carbon, making them stronger and more durable. On the other hand, cast iron pipes are made solely from iron, which makes them more brittle and prone to cracks. Additionally, steel pipes have a smoother interior surface, allowing for better water flow and reducing the chance of clogs. Cast iron pipes, on the other hand, have a rougher interior surface and are more susceptible to corrosion. Overall, steel pipes are typically preferred for their strength and longevity, while cast iron pipes may be used in specific applications where their unique properties are advantageous.

- Q: What are the different types of valves used with steel pipes?

- There are several types of valves used with steel pipes, including ball valves, gate valves, globe valves, check valves, and butterfly valves.

- Q: Welded and seamless steel pipe how to distinguish?

- Different price:Because the production process of seamless steel tube is more complex, so the price is more expensive than a seamed steel pipe, and pipe joints mainly adopts steel (steel) two welded, fixed price, the most widely used are.

- Q: Can steel pipes be used for fencing?

- Yes, steel pipes can be used for fencing. Steel pipes are durable, strong, and resistant to corrosion, making them an excellent choice for fencing applications. They can be used to create secure and long-lasting fences in various settings, such as residential, commercial, or industrial properties.

- Q: Can steel pipes be used for structural purposes?

- Yes, steel pipes can be used for structural purposes. Due to their high strength, durability, and resistance to various environmental factors, steel pipes are commonly used in construction for applications such as supporting structures, frames, and columns. They offer superior load-bearing capacity and are especially suitable for use in large-scale infrastructure projects.

Send your message to us

13 3/8" 54.5ppf API 5CT casing pipe BTC end

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords