Fiberglass Mesh Cloth 120g/m Marble Mesh for Buildings

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

120g/m Fiberglass Marble Mesh for Buildings

Definition of Fiberglass Marble Mesh

Fiberglass Marble Mesh is mainly alkali-resistant fiberglass fabric. Fiberglass Mesh mainly use the C /E-glass fiber yarn (main ingredient is a silicate, good chemical stability) through a special weaving technique, then by the anti-alkali and reinforcing agent etc high temperature heat finishing treatments. Fiberglass Mesh is an ideal engineering material in construction and decoration industry.

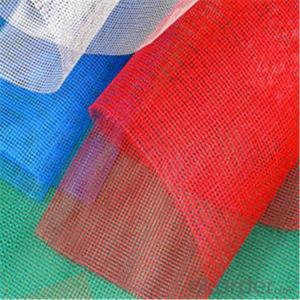

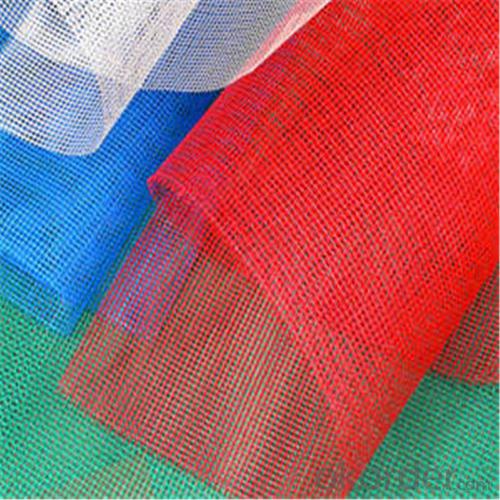

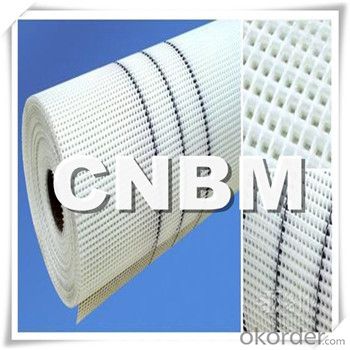

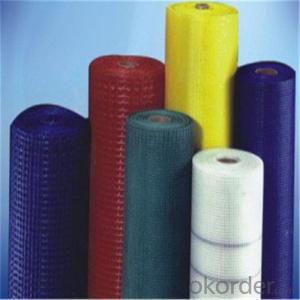

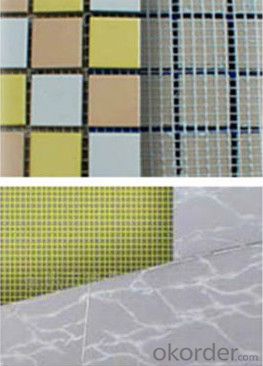

Image of Fiberglass Marble Mesh

Application/Usage of Fiberglass Marble Mesh

External thermo insulating composite System (ETICS) & External insulating finish system (EIFS)

External and internal plaster reinforcement Fiberglass Mesh, Electrical heating mats Fiberglass Mesh

Marble slab reinforcement / Mosaic carrier Fiberglass Mesh, Asphalt reinforcement (roof water-proof) Reinforced lightweight construction boards Fiberglass Mesh.

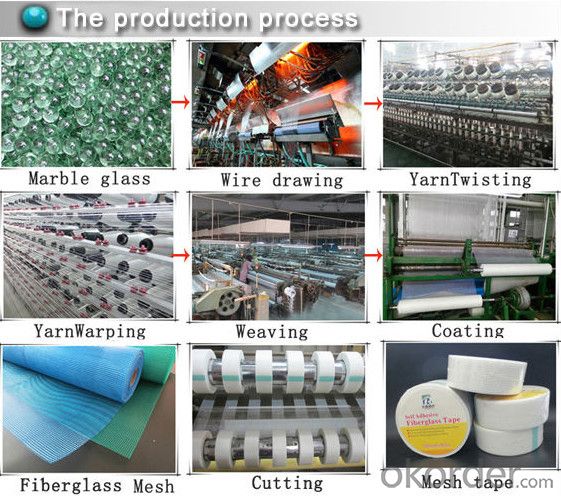

Fiberglass Marble Mesh Production Process

Application :

Package: Fiberglass Marble Mesh are packed in shrink-wrapped, then put into cartons or pallets.

Packing volumes: about 20000m/20FCP, 40000m2/40HQ.

Delivery: About 15 days after confirming the order.

FAD:

Q: What is the storage of Fiberglass Mesh?

Store Fiberglass Mesh out of direct sunlight, away from direct contact ground or concrete;

Store Fiberglass Mesh rolls in cool, dry location, away from weather or other damage.

Q: What is the guarantee period of Fiberglass Mesh ?

Fiberglass Mesh: Four years under normal weather conditions and usage directions.

Q: What is the Advantage of Fiberglass Mesh ?

Good chemical stability: Alkali-resistant, acid-resistant, waterproof, cement erosion-resistant, and other chemicals' corrosion resistant; and strong resin bonding, soluble in styrene.

Outstanding craftsmanship include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after test in Naoh 28days later, so that guarantee high strength, high tensility, light weight.

Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it's 20% extra strong strength and beauty surface than normal fiberglass yarn.

Strength retention rate> 90%, elongation<1%, the durability of more than 50 years.

Good dimensional stability & positioning property, stiffness, smoothness an difficult to shrink & deformation.

Good impact resistance and not easy to be teared.

Q: Why choose our CNBM Fiberglass Mesh?

We are the manufacturer of Fiberglass Mesh, price will be reasonable and much competitive

We have produced Fiberglass Mesh strictly in according to customers' detailed requirements

CNBM Fiberglass Mesh theme is: Good Quality, High Credibility & Best Service.

- Q: How to fill the sample size of glass fiber mesh cloth, fill what general specifications

- Mesh size: 5mm*5mm, 4mm*4mm: net weight: 80g---160g/ square meters per roll length: 50m, 100m or 200m.

- Q: Glass fiber mesh cloth bent do to straighten it?

- Of course not, because of hard and soft and orientation relationship, different product positioning different soft and hard to do it, and a product is related to raw materials, and then coated on the surface of the adhesive is below, introduced from two aspects respectively.

- Q: Glass fiber mesh cloth, crack mortar, tiling there is no problem?

- Now, many sites are pure in the transfer problem of various types of work, if the base treatment bends up, after the winter freeze will soon fall, you can put the case to the party to write a material, as long as you don't sign the party a no problem.

- Q: Can fiberglass mesh waste be recycled? What can you do if you can?

- What is more the incineration of waste mesh, which is of serious pollution damage behavior of soil air, acrylic mesh after high temperature can produce pungent odor, destroying the respiratory system and strong material, the core material is flame retardant fiberglass mesh product is burning up, so it is a serious pollution of soil caused by.

- Q: Glass fiber mesh fabric stereotypes poor, general use of glue is acrylic emulsion, please add what accessories, you can finalize a better shape

- Add a bit of gum, and the mesh will become harder

- Q: What is the difference between alkali resistant fiberglass mesh and glass fiber mesh fabric?

- Glass fiber mesh fabric is based on glass fiber woven fabric as its base material and is coated with high polymer emulsion.

- Q: Glass fiber mesh cloth, pure gold pot with what glue out, finished products can be detected, as well as the proportion of glue is how much?

- 1, first of all, from the material, imitation gold pot mesh cloth, its warp is Kim Nabesa, weft is Tonabe Sa, this is called "imitation gold pot" mesh cloth one aspect.2, and then, imitation gold pan mesh cloth looks like the appearance of the gold pan mesh cloth is exactly the same, so it has become imitation gold pot.3, and finally, the quality of imitation gold pan mesh cloth can never be better than the quality of the gold pan mesh cloth, which is also called "imitation gold pot" one of the reasons.

- Q: What is the difference between alkali resistant fiberglass mesh cloth and high alkali glass fiber mesh cloth?

- Alkali resistance refers to the performance of special glass fiber, while high alkali refers to the composition of glass fiber.Are two completely different concepts.

- Q: Slotted walls, seams, seams, tape, or anti mesh cloth?

- Because in the fiber wall sealed with aging, so. Then through the plaster smooth dry, tore the cloth into strips, glue brush in the gap, and then dried, powder, and will not crack, affordable, the effect is very good.

- Q: What is the use of alkali resistant fiberglass mesh cloth on the exterior wall?

- How to identify quality problems of alkali resistant glass fiber cloth, glass fiber cloth market price of 1. of the worst is usually around 1 yuan -1.60 yuan, his glass fiber is usually made of some kind of waste glass beer bottles, the production process for clay crucible drawing, production process is prohibited by the state, the surface coating is non alkali resistant emulsion. From the intuitive point of view: the work is relatively rough, generally sold in the market volume of the theory, often lack of length, grams of weight is not enough, two fold on the break, the contact is not firm, easy to shift, and easy to stab the skin. In the insulation layer in general in the two months after the loss of strength using the grid cloth, if the mortar off grid cloth out, just gently crushed, fiberglass yarn is made into powder.

Send your message to us

Fiberglass Mesh Cloth 120g/m Marble Mesh for Buildings

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords