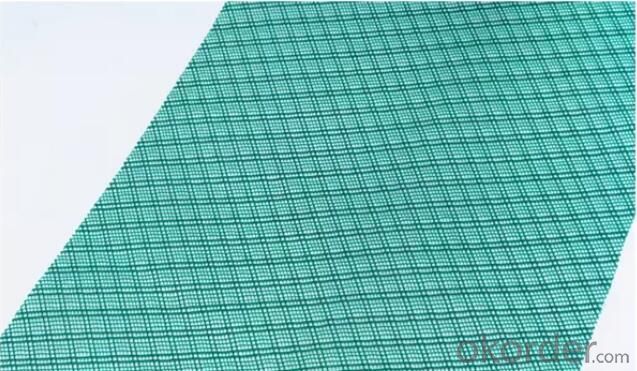

110g Green Plastic Net Flow Media For Resin Vacuum Infusion Process

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin:Zhejiang, China

Brand Name:suretex

Model Number:extruding flow media

Weight:100gsm, 160gsm, 230gsm

Temp Resistance:150

Color:Green

Mesh type:extruding

Width:1.2m, 2m

Application:Resin infusion process, prepreg process

Material:HDPE

MOQ:200sqm

Packaging & Delivery

Packaging Details

Vacuum Infusion Process RTM, infusion flow mesh, resin flow media, plastic film

Port

shanghai

Lead Time:

Quantity(square meters) | 1 - 200 | 201 - 2000 | >2000 |

Est. Time(days) | 7 | 15 | To be negotiated |

Flow media is mainly used in vacuum infusion process, it can make the resin fast infiltrate into any part of the products.

Code | Gram(g/m2) | Color | Width(mm) | Temp . Resistant(°C) | Type |

1 | 100 | Green | 1200 | <=150< span=""> | extruding |

2 | 200 | Green | 1200 | <=150< span=""> | extruding |

3 | 230 | Green | 1200 | <=150< span=""> | extruding |

- Q: What's difference between iron rust and protective film of aluminum?

- The iron rust is red. Aluminium is ligher than iron but it's easy to react with salt and vinegar and separate out toxin.

- Q: The introduction of protective film

- Protective film can be made from materials like PET and AR. There are many types of protective films. And the film can be used on many items including the screen of mobile phone and stainless steel.

- Q: Mobile phone screen film stuck on how bubbles ah, how sticky ah?

- To introduce you to a good use of protective screen, as long as you gently put down, you can self adsorption, without any bubbles, dirt, very perfect - Peacock screen - screen protection experts, the first self adsorption glass protection screen! The proprietary technology of self - adsorption, fully transparent and explosion-proof glass has been used to subvert the characteristics of the old screen saver with a new design structure.

- Q: How to define the adhesion degrees of protective film?

- At present, there's no such internatinal standards. Each company has its own standards. It's for reference that the adhesion of protective film is usually classified into four degrees which are slight, low, meidium, and high. Generally, 0.02-0.1N refers to slight degree; 0.1-1N,low degree; 1-2N, medium and 2-6N, high. But this is not always the same. It depends on the requirements of themanufacturers.

- Q: Is there any skillful way to remove the protective film on aluminium-plastic panel?

- It will be really fast to remove it if you heat it with electric hair drier at the same time.

- Q: What to do if there are some white dots on the protective film coated on high-light product?

- Please use protecive film of better quality. The foggy white dots may be generated because the glue reacts with the air.

- Q: When should the protective film of mattress be torn off?

- You can remove it when you begin to use the mattress. The protective film is bad to health.

- Q: Is it good to stick a protective film on a laptop or not?

- We know that the LCD protective film factory configuration is a layer of plastic film, and the film, not only greatly affect the visual effects, reduce the permeability and have a lot of reflection, will affect the user's eye. In addition, the heat dissipation of the display is extremely unfavorable. The plastic film is not a good conductor of heat. The liquid crystal panel will heat up after a period of time, and touch the panel with the back of the hand. You can tell that the temperature is very high. If the surface is coated with a protective film with poor thermal conductivity, it virtually prevents the cooling of the liquid crystal and even shortens the effective life of the display.

- Q: How to tear off the protective film on the stainless steel security door?

- The reason why you can't remove the film is that the outer film made from polyethylene material chemecally reacts with the surface paint of the door. And the film and the paint stick to each other. You can clean the film with some of the paint using thinners. But I think it doesn't affect too much.

- Q: What are the functions of pure gum protective film?

- Functions of insulation and seal.

Send your message to us

110g Green Plastic Net Flow Media For Resin Vacuum Infusion Process

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches