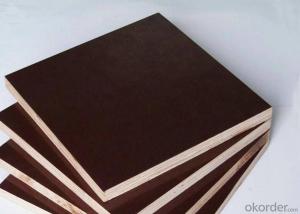

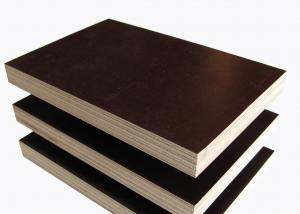

11/32 Brown Film Faced Plywood / Black Brown Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick Details

| Type: | Plywoods | Place of Origin: | Guangdong China (Mainland) | ||

| Model Number: | 1220*2440 | Usage: | Outdoor | Grade: | First-Class |

| Main Material: | Poplar | Formaldehyde Emission Standards: | E0 | Plywood Type: | Veneer Boards |

| Veneer Board Surface Finishing: | Double-Sided Decoration | Veneer Board Surface Material: | poplar |

Packaging & Delivery

| Packaging Detail: | pallet packing and as requested |

| Delivery Detail: | 15 days after receiving your deposit |

Specifications

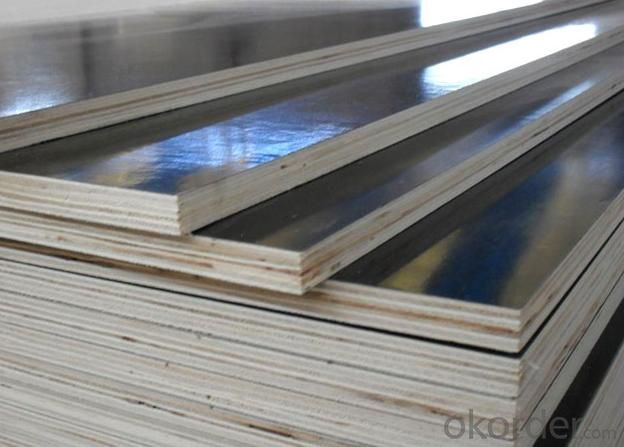

black or brown Film Faced Plywood

1)Face:Black film and brown film

2)Core:Poplar,pine,birch

3)Glue:WBP,MR glue

1.High bending strength

2.Strong nail holding

3.Moisture-proof and easy work

4.Tight construction and high strength

5.No ratten or decay

6.Low formaldehyde emission

7.The productions are suitable for the construction of viaduct and tall frame building

8.If put in boiling water for 48 hours,it still glue sticking and still formed

9.If used abide by illustration strictly,it can be reuse more than 50 times

10.Solve the problem of leaking and rough surface during construction process

black or brown Film Faced Plywood

1)Face:Black film and brown film

2)Core:Poplar,pine,birch

3)Glue:WBP,MR glue

4)Size:1220*2440 1250*2500,1200*1800

5)Thickness:12mm 15mm 18mm 20mm 21mm or as required

6)Certification:ISO9001 and ISO14001

7)Other:with waterproof paint seal the edge.

8)Production Capability:10000 Pieces Per Day.

- Q: according to the use of plywood can be divided into needle plywood and broadleaf plywood.

- Ⅲ, Ⅳ plywood moisture content of not more than 15%). ③ quality. Finished products should have rectangular straight edges and obvious edges and corners;

- Q: triple? Nail gun Self-tapping screws? Cork Or other?

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q: How to use building plywood?

- Building plywood is mainly used in outdoor conditions, such as building decoration and concrete template

- Q: Further processing of the plywood

- veneer plywood overlaid plywood. Plywood plywood, wood, paper, impregnated paper, plastic, resin film or sheet metal plywood.

- Q: Multilayer plywood with what method is fixed

- Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood, and then made of adhesive glue from the three or more layers of plate-like materia

- Q: What is the density of plywood?

- Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood, and then made of adhesive glue from the three or more layers of plate-like material,

- Q: Distinguish between multilayer boards and plywood

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences.

- Q: Why is the plywood commonly used in the singular layer

- This is a good understanding of the regardless of the plywood and plywood they are for the sake of their each of them are vertical lines of the

- Q: Decorative veneer veneer plywood features

- As the product surface of the decorative veneer is made of high quality wood by slicing or peeling processing method, so the plywood has a better decorative performance

- Q: Does plywood contain formaldehyde?

- 12 cm plywood is usually 3-4 layers of natural wood chips "glue" together, each layer of double-sided roller plastic hot forming, the whole board about 3 kg of glue

Send your message to us

11/32 Brown Film Faced Plywood / Black Brown Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords