1000C Micropores Insulation Board with Good Quality and Low Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CMDS Microporous Insulation Board is specially designed for steel industry & metallurgy with very good thermal and mechanical properties.

It is an ideal back-up insulation for various industry where the high temperature is needed, with a long time exposure of 1150 °C at highest.

M5100 Panel ---Various coverings : Naked Panels, Aluminium Foil covering, E-class Fibre Cloth Covering, Fibre Paper covering.

M5100 Panel—Four Grades available : 850 , 1000, 1100, 1200

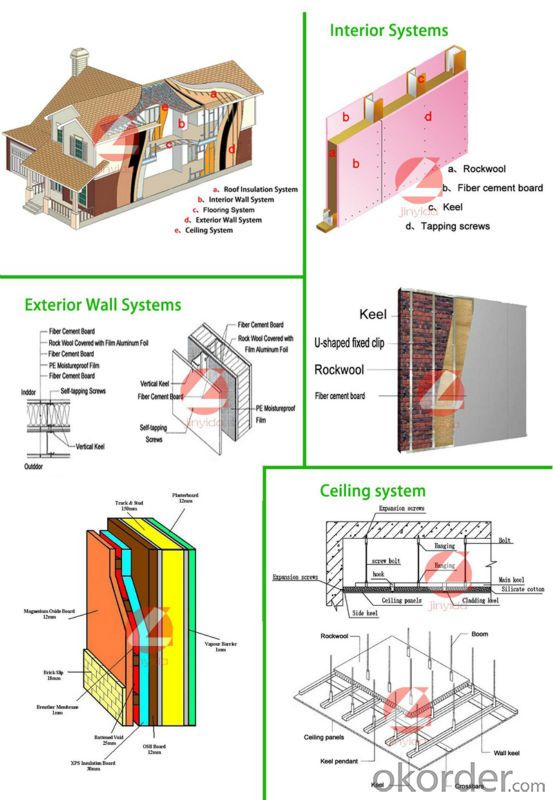

Product Applications:

Microporous Insulation Board are ideal for use in the below applications

Ladles

Torpedo Ladle

Tundish

Cement Rotary Kiln

Glass & ceramics industry

Petrochemical industry (cracking furnace, reformer)

Black box & VDR (Voyage Data Recorder)

Data loggers

Product Advantages:

CNBM has success in its Microporous Insulation Board due to their cost-effectiveness and excellent insulating properties. CNBM also has experience in ceramic fiber blankets application and would like to assist you in product selection, system design, and installation techniques.

Main Product Features:

Extremely low thermal conductivity

High compressive strength

No harmful respirable fibres

Free of organic binders

Environmentally friendly

Product Specifications:

FAQ:

Q1: Why buy Microporous Insulation Board from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3.What is necessary for quotation?

A 3The info is the more detailed the better, like size, temp, al2O3 content etc.

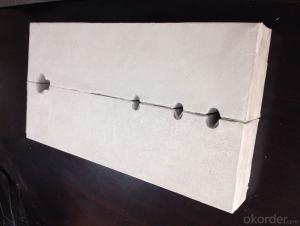

Product Picture

Produce Processing

- Q: What are the production methods of calcium silicate board material?

- At present most of the static process, the raw materials and auxiliary materials according to a certain proportion, adding an appropriate amount of water, while stirring heated to a certain temperature of the gel, and then after molding, autoclave curing, drying is calcium silicate insulation material products. In static method, diatomite is used as siliceous material, calcium material is more lime. The process is simple, low cost, but when the production needs of large capacity and high pressure kettle, the reaction is not complete, the main form of Tobey mullite type calcium silicate board, the use of low temperature (<650 degrees Celsius), it is difficult to produce light and ultra light high strength products.

- Q: Which is better, asbestos free calcium silicate and aluminium silicate refractory fiber?

- Aluminum silicate fiber can be divided into many kinds according to the aluminum content, the use temperature range is relatively large, the heat insulation property is good, but the price is more expensive.

- Q: What is the maximum temperature at which the glass is cured?

- The softening point of quartz glass is 1600 degrees, it is sodium phosphate and phosphate. Gas burner 1300 degrees, after homogenization processing, after annealing treatment of glass products.

- Q: Calcium silicate board for house ceiling, 6mm or 8mm?

- Mineral wool board ceiling is different than the calcium silicate board ceiling. Or with the calcium silicate board, mineral wool board first big thickness, increase the keel pressure, easy to cause the ceiling of the cave. Second, it is easy to produce some bug mineral wool board. The fire performance of third mineral wool board no calcium silicate board, mineral wool board fourth dampeasily yellow, moisture absorption is not good.

- Q: What are the three major effects of fly ash in concrete?

- Fly ash "micro aggregate effect" in the fly ash particle size is very small beads and debris in cement can be the equivalent of unhydrated cement grains, tiny beads equivalent to nano material and lively, can significantly improve and enhance the structural strength of concrete and improve the homogeneity of products, and compactness.

- Q: Cement is not silicate products

- Usually refers to silicate products with lime (calcium containing materials) and sand, fly ash, slag (siliceous materials), then add a small amount of gypsum, the steam steam curing or steam curing, building products quickly generate Tobey mullite, calcium silicate, hydrated calcium aluminate sulfate and hydrated calcium aluminate such as cementitious materials and production. Such as: autoclaved fly ash (sand), autoclaved aerated concrete, autoclaved fly ash brick, autoclaved sand lime bricks.

- Q: Eterpan and yinte in what is the difference?

- Calcium silicate board:Calcium silicate board is mainly inorganic mineral fiber or cellulose fiber and other loose short fiber materials with siliceous and calcareous materials as the main cementing material, pulping, molding, in high temperature and high pressure saturated steam curing acceleration, sheet formation of calcium silicate gel made.Calcium silicate board is a new type of building and industrial plate with excellent properties. Its products are fireproof, moisture-proof, soundproof, moth resistant and durable. It is an ideal decorative board for ceiling and partition. Excellent waterproof performance, just can prevent the home improvement for a long time damp deformation, especially in the bathroom for a long time in a humid environment, the use of calcium silicate board ceiling is the best choice.

- Q: What is the main role of fly ash added in concrete products?

- The rational use of fly ash in concrete, not only can replace part of cement, reduce the construction cost, but also because of its unique properties can be effectively used for the various requirements of the use of concrete, improve and enhance the performance of concrete.

- Q: What is dew point of thermal insulation material?

- Insulation materials, insulation for industrial equipment and piping, thermal insulation measures and material aerogels were first applied to the space suit thermal insulation linings developed by nasa. With low thermal conductivity, small density, high flexibility, fire, waterproof and other characteristics. Its temperature coefficient of thermal conductivity 0.018W/ (K = m) and absolute waterproof, insulation performance is 3~8 times of traditional materials.

- Q: What are the exterior walls of the building besides the benzene board and the extruded board?

- Calcium silicate insulation insulation materials in 1980s has been recognized as the massive rigid insulation materials in one of the best, which is characterized by low density, high heat resistance, low thermal conductivity, flexural strength, high compressive strength, low shrinkage. But after entering 1990s, the promotion of the use of a downturn, the main reason is that many manufacturers to adopt in order to solve the problem of non asbestos fiber pulp, pulp fiber and not due to high temperature, thus affecting the thermal insulation material of high temperature resistance and increase the breaking rate, and not the economy.

Send your message to us

1000C Micropores Insulation Board with Good Quality and Low Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches