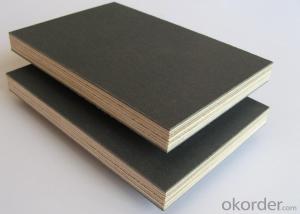

1 Thick Okoume Core Plywood

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1x40' FCL m³

- Supply Capability:

- 20000M3 Per Month m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Infomation of Okoume Core Plywood

Okume Face & Core (full okoume wood) plywood is a special type of plywood that is commonly used in marine applications such as

boat building. It is made from select grades of okume wood of the highest quality. Using this type of plywood can provide you with a

number of unique benefits. Consider the following advantages of okume plywood to decide if it is right for your application.

1. Water Resistant glue to be used.

WBP gule OR phenolic gule

2. pliable

Another big advantage of okoume plywood is that it is highly pliable. This type of wood can be bent and still maintain its structural integrity,

not automatically snap or crack like a lot of the other types of plywood will. This is another reason that it is frequently used in boats, and

it widens its range of applications

3. Impact Resistance

Marine okoume plywood also offers superior impact resistance. The outside layer of the plywood is extremely hard and dense. This means that if you

drop something on it or something runs into it, it will not necessarily dent or break. This makes it an ideal choice for projects that will undergo

a lot of regular wear and tear. You do not have to worry about replacing the plywood a few years down the line. It should be able to stand up to

a lot of abuse without many issues.

4. Surface Finish

With this type of plywood, you will also get superior surface finish characteristics. Many plywoods can not be finished smoothly, which could make

it too rough for some types of project. With marine plywood, you can get a very smooth finish that is soft to the touch. Not only will you have to

worry about splintering when you build with it, but you can also paint or stain it to create any look that you want to go for. The design options with

this type of plywood surface are virtually limitless.

Fast planing boats are subjected to serious bottom pressure and marine plywood should be used for the hull panels if

only for mechanical reasons. The designer of your planing power boat probably specified marine plywood for that reason.

Large displacement type boats that spend all their time in the water, at the dock or at sea, should also use marine plywood.

While the fiberglass and resin will protect plywood, any scratch or dent may allow moisture to creep in and

damage cheaper plywood. Marine plywood will give you peace of mind in addition to all the advantages listed above.

Specifications of Okoume Core Plywood

1)size: 1220mm×2440mm, 1250mm×2500mm,

Thickness: 3-40mm

2)face: okoume veneer , B grade or better

3)Core: full okoume Core , B grade or C+ grade

4)Glue: WBP or phenolic glue

- Q: What does plywood mean and its synthesis?

- usually with odd-level veneer, and the adjacent layer of veneer Of the fibers are perpendicular to each other.

- Q: triple? Nail gun Self-tapping screws? Cork Or other?

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences

- Q: Commonly used plywood, pallets and so on

- straw and other things containing wood fiber, very cheap, so the cost of producing MDF is very low so the market price is cheaper than the solid wood.

- Q: What types of plywood can be divided into?

- Class I (NQF) - weather resistant, resistant to boiling plywood Class II (Ns) - Water resistant plywood.

- Q: Wood board, plywood, MDF What is the difference

- Blockboard is the core board made of wood board stitching, the two surfaces for the sticky wood veneer solid plate. Veneer, also known as the table, below the board by the board of a board said plate.

- Q: The density of the plywood is greater than that of the same kind of wood

- The greater the unit pressure when gluing, the greater the density of the plywood. As the wood at high temperature easy to produce plastic deformation, hot glue gluing than the compression of the compression rate is greater.

- Q: What are the key points for plywood selection?

- if you do not consider the panel pattern and color, should also be based on the environment and reasonable cost Selection of plywood grade, category

- Q: What is the difference between plywood glue E0E1?

- Urea-formaldehyde glue: moisture-proof glue / for interior decoration, furniture, can not be used for outdoor.

- Q: What is the amount of construction works used for this plywood?

- A class of plywood for weather resistance, resistance to boiling water plywood, which and he has a durable, high temperature, the advantages of steam treatment;

- Q: One of the commonly used materials for furniture is a wood-based panel

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each othe

Send your message to us

1 Thick Okoume Core Plywood

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1x40' FCL m³

- Supply Capability:

- 20000M3 Per Month m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords