Finish Plywood Bintangor Face and Back Plywood for Door Skin 3'x7' MR Glue

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction:

Plywood is made of three or more thin layers of wood bonded together with an adhesive. Each layer of wood, or ply, is usually oriented with its grain running at right angles to the adjacent layer in order to reduce the shrinkage and improve the strength of the finished piece. Most plywood is pressed into large, flat sheets used in building construction. Other plywood pieces may be formed into simple or compound curves for use in furniture, boats, and aircraft.

Product Name: Bintangor plywood

Face/Back: Bintangor

Core: Poplar,Hardwood,Pine,Birch,Eucalyptus,Combi etc

Size: 1220×2440mm,1250×2500mm,1220×2150mm,1830×3660mm etc

Thickness: 2.7-30MM

Thickness Tolerance: +-0.1mm~0.3mm <6mm< span="">

+-0.3mm~0.5mm >6mm

Glue:WBP/MR/MELAMINE/E0/E1/E2

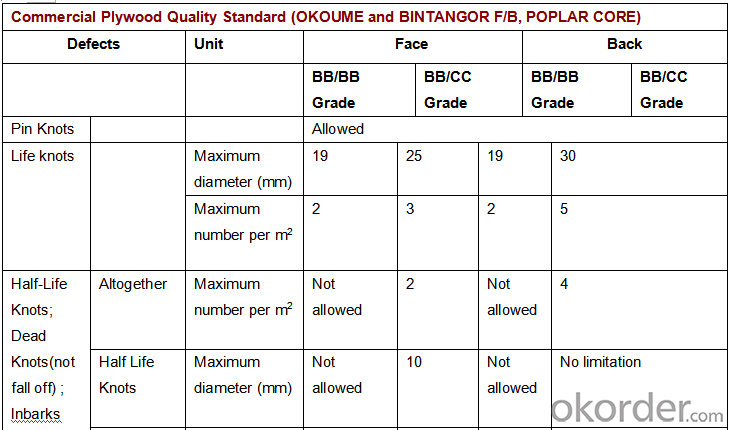

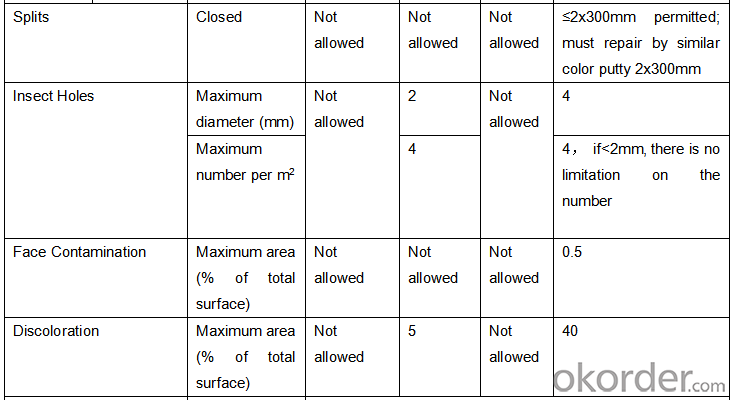

Grade:BB/BB BB/CC CC/CC etc

Moisture: 8-14%

MOQ: 40HQ

Packing Details: 20GP 8pallets/21M3

40GP 16pallets/42M3

40HC 18pallets/53M3

Payment Terms: 30%T/T in advance,70%L/C

Delivery Time: 15 to 20 days after receiving 30%T/T down payments

- Q: triple? Nail gun Self-tapping screws? Cork Or other?

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences

- Q: According to the different composition of the glue, for the construction of plywood with the following types of glue

- E0 is the highest environmental rating. E1 grade glue to do the plywood can be used directly for the interior.

- Q: How do I determine if plywood contains formaldehyde?

- At the same time, in the purchase of furniture, try to choose the wooden rather than plywood production

- Q: Multilayer board and plywood difference

- A group of boards are usually made of mutually adjacent panels in the direction of the adjacent layers.

- Q: The Preparation of plywood ingredients

- core core core sandwich panel or composite plywood center layer. Usually its thickness is greater than the other layers.

- Q: Ordinary plywood is divided into four categories

- According to different density, divided into 80, 70, 60 three categories. Quality level for the premium, one, two three

- Q: Multilayer board, also known as three plywood and plywood

- . Its main advantages and disadvantages of raw materials, Liu An core 1.2m.4m each board price of 10-20 yuan. And the peach core and poplar will be cheaper.

- Q: Now the market prospects for plywood

- regulate export order. With the expansion of China's infrastructure construction and the strengthening of the development of the Midwest, plywood market has great potential.

- Q: One of the commonly used materials for furniture is a wood-based panel

- usually its table and the inner plate symmetrically arranged in the center layer or plate on both sides.

- Q: What are the shortcomings of plywood

- Plywood is one of the common materials for furniture, one of the three panels of man-made board, but also for aircraft, ships, trains, cars, construction and packaging materials

Send your message to us

Finish Plywood Bintangor Face and Back Plywood for Door Skin 3'x7' MR Glue

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords