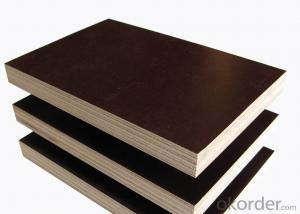

1/4 Black Film Faced Plywood Hardwood Core for Concrete Form Work

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Black film faced plywood hardwood core

General Information of Black Film Faced Plywood Hardwood core

1.Size(mm): 1220x2440; 1250x2500 Thickness(mm):18; 15; 12; 20; 21

2.Glue: MR, melamine, phenolic, WBP

Core: hardwood

3.Film: black film or as requested Color: black

4.Application :Construction material used for concrete forming mouldings.

5.Standard ISO9001

Packaging & Delivery

1.Packaging Detail: loosing package,pallets package,all can according to customers'requirements

2.Delivery Detail: delivery within 10 days after get the deposit

Specifications of black Film Faced Plywood

1.Usage:Decoration,Furniture,Construction.

2.Package:Inter packing:0.2mm plastic bag. Outer packing:Pallets are coverd with plywood or carton

3.Min order 1*20FCL or 23 cubic meter

4.Payment terms:L/C at sight,T/T 30% as deposit ,D/P.

5.Supply ability:6000 Cubic meter/month or 8000 pcs/day.

6.Main marke:Indonesia Malaysia India,Thariland,Middle East,Europe,Africa.

Advantage of black Film Faced Plywood

1.No wapping, no fracture,not out of shape , it can stay 24hours in boiling water.

2.Good performance and more turnover use time.

3.It is easy to take off the membrane;Time is only 1/7 of the steel mould.

4.Make the surface of concrete more smooth and beautiful,so it can be easy to make decoration and it also deduct the processing of plastering.

5.This can moderate and contact 30% time for a project.

6.Corrosion resistant and ir will nor pollute the surface of concrete.

FAQ:

① why from okorder?

Okorder is a qualified supplier of all kinds of building matierials in China. All products have been showed in Okorder website are under well controlled by okorder QC team.

All products had been produced under a clear quality standard and the quality is consistence among the shipments.

Okorder has already setted up more than 20 warehouses in different markets to show the products. You are convenient to know the products from your local place and it will help you to make decision easyly.

②How to guarantee the quality of the products?

We have established a perfect quality management system,as for raw material and semi parts all are under strict quality test and we have a IQC system to control the purchases.

QC on site is very strict and all steps of process are measured per drawings. Before delivery, we set a OQC system to make sure each piece meet the standard of order.from design to delivery,

③How long can we receive the product after purchase?

Lead time depending on order quanity, The normal order can be deliveried with 3 weeks.

- Q: National standards for decorative veneer veneer plywood performance requirements

- GB 18580-2001 "interior decoration materials, wood-based panels and their products in the formaldehyde release limit" also provides the product of formaldehyde emission limit.

- Q: defects are divided into four grades

- Sanding plywood refers to the plywood of the sanding machine (or scraper) sanding (or scraper).

- Q: Now what is the market for plywood development?

- From January to November 2007, China's plywood manufacturing industry achieved a total industrial output value of 101,828,484 thousand yuan, an increase of 48.27% over the same period last yea

- Q: Judging wood is the standard for plywood

- If you have an old piece of furniture, it is time to polish or throw it away, then you can make a decision by identifying the wood sometimes.

- Q: Commonly used plywood, pallets and so on

- so it will not crack, but it can not be called solid wood, and now the market has solid wood particle board, MDF, particleboard and other components of the plate Is wood chips, sawdust,

- Q: Further processing of the plywood

- veneer plywood overlaid plywood. Plywood plywood, wood, paper, impregnated paper, plastic, resin film or sheet metal plywood.

- Q: How is the current market outlook for plywood?

- Although China plywood has developed rapidly, but still encounter the EU and other importing countries of the anti-dumping complaints

- Q: What are the defects in plywood material?

- holes In the process of shipment, holes are caused by hooks and tools for workers' picking.

- Q: The density of the plywood is greater than that of the same kind of wood

- As the plywood from the criss-cross the preparation of the veneer, the thermal conductivity is lower than the same species of wood

- Q: Today, most of the furniture is made of wood, pine, bakelite and popla

- . At that time, high-quality furniture, timber supply is sufficient, those who are not beautiful or poor durability of wood used only for non-exposed parts of furniture.

Send your message to us

1/4 Black Film Faced Plywood Hardwood Core for Concrete Form Work

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords