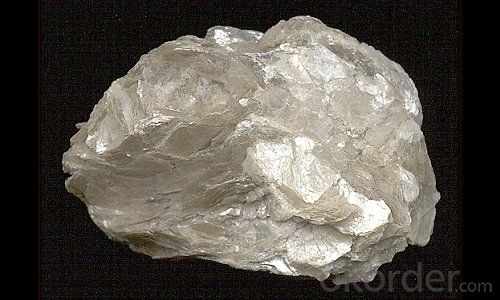

Raw Materials for Refractory:1-3mm White Mica for Refractory Field

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Introduction of mica

1.Mica is a kind of rock-forming minerals. Its form is platelike or flaky.The colour is variable with the differences of chemical composition. Mainly Fe content increase will make the colour be darker.

2. The characteristics of mica contains: insulation,high temperature resistant,lustrous appearance, stable physical and chemical property,good heat insulation, excellent elasticity and high toughness etc.

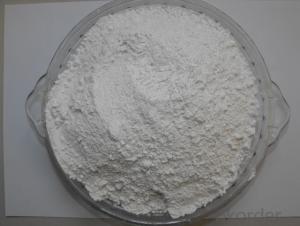

Particle Size of mica

It contains 3-5mm,1-3mm,15mesh,20mesh,40mesh,60mesh,80mesh ,100mesh,200mesh,325 mesh ,400 mesh etc.

Physical Property of mica

Diameter-thickness. Ratio | Whiteness | Refractive Index | Specific Gravity (g/cm3) | PH | Moisture | Sand Content | Colour |

1:30 | 50-70 | 1.58 | 2.8 | 6.5-7.5 | ≤0.5% | ≤1.0% | Silver white |

Chemical Composition of mica

ELEMENT | SiO2 | Al2O3 | Fe2O3 | K2O | Na2O | MgO | CaO | LOI |

CONTENT(%) | 44.3 | 31.21 | 5.74 | 10.58 | 1.17 | 0.62 | 0.57 | 4.97 |

Application of silver mica

Muscovite is used in industry mostly, the second is phlogopite.Mica is used widely in building materials industries, fire-fighting industries, fire extinguishing agent, electric welding rod, plastics, electric insulation, papermaking, asphalt paper,rubber,pearl pigment etc.

- Q: What kind of flexible fireproof material is really good?

- Flexible waterproof materials mostly are asphalt, linoleum and other organic material, which is also called linoleum coiled material waterproof layer. it uses the linoleum, glass cloth fabric as tire layer coil, using all kinds of cementing material phase of asphalt and so on. Make coil bind on roof structure plate leveling layer to form waterproof layer. Flexible waterproof material has high tensile strength, big elongation and light quality, which is convenient to construct. But it has relatively strict operation technology can resistant penetration and aging resistance than rigid materials, aging. Its life is short. Refers to a kind of waterproof material form relative to the rigid waterproofing materials such as waterproof mortar and waterproof concrete. In the form of its and grassroots attached two categories, it includs waterproof coating and waterproofing materials. According to different paste position of waterproof material, it can be divided into outside waterproof waterproof (outsourcing) and inside waterproof (insourcing waterproof) two kinds. Waterproof coil material must be stuck in the grass-roots that have enough stiffness of the. Before pasting, you should apply leveling layer and waterproof layer should be added protective layer of the outside, and need to make the rotation of the flexible material, the processing of subsequent and head closing, in order to ensure the continuity of the waterproof layer and sealing. In addition, there are all kinds of waterproof material and moistureproof coating material.

- Q: who knows the fire resistant levels of fireproofing glass?

- According to the fire resistance levels, it can be divided into three categories: Class A: a kind of fireproofing glass that can satisfy the requirements of refractory integrity, refractory and thermal insulation at the same time. Including composite flameproof?glass and perfusion type fireproofing glass . This kind of glass has the properiyies of transmittance, fireproofing ( smoke insulation, fireproofing, and keeping out thermal radiation), sound insulation, shock resistance, and it's suitable for steel and wooden fire door of building decoration, windows, varnishing, partition walldaylighting?roof,ceiling?screen,perspective floor and other construction components demading for transparency and fireproofing. Class B: Marine fireproofing glass, including porthole fireproofing glass and rectangular window fireproofing glass, surface glass pane is tempered safety glass, the inner surface glass pane material can be arbitrary selection. Class C: it's a kind of monolithic fireproofing glass that only satisfies the requirements of refractory integrity. This kind of glass has characteristics of transmittance, fireproofing, smoke insulation and high strength,etc. It's suitable for fireproofing glass partition wall, fire Windows, outside curtain wall and other places without insulation requirements.

- Q: Can quantitative feeder be used in refractory plant? Thank you

- Yes, but the material must be no longer using a simple Q235 material

- Q: I know which material is the fire resistance rolling shutter door

- Inorganic fiber cloth as curtain side replace steel fire shutter curtain of steel plate, the thickness of the inorganic fiber cloth is much thinner than the steel curtain plate and the density is very small, so the volume of the same area of ??the inorganic fiber is super fire shutter the same area of ??steel fire shutter half, and weighs only one more out of the same area a few steel fire shutter, however, the inorganic fiber super fire shutter fire but has a very good insulation properties. I hope my answers are helpful to you.

- Q: What's the poured refractory material?

- According to its category, raw material of basic refractory: Mainly magnesite (magnesia), dolomite, lime, olivine, serpentine, high alumina material (sometimes neutral); main neutral raw material: chromite, graphite, silicon carbide (artificial).

- Q: What refractories are accessible with ease in daily life? This material is suitable as a disposable mold and crucible for melting brass.

- Well, you have no furnace to cast disposable molds. You can sieve sand which is used for blending cement with siever (left the most fine behind)! And then you can go to hardware (parts) factories directly with molds to ask them to pour. Remember that brass (60 copper) needs to be heated to 1200 ℃, while the crucible is not needed.

- Q: Could you tell me how does fire protection standard of decorative material is divided?

- Building materials can be divided into four levels according to combustion performance (non-combustible, flame retardant, flammable, flammable). According to the Code for Design on Building Fire Protection and Prevention (GBJ16-1987) (revised in 2001):, the fire risk of production or storage is divided into a, b, c, d, e classes. Divided by plate material: structure material, base layel materials and fabric; Divided by fire protecrtion type: easy to burn, difficult to burn, flame retardant, incombustible material. Material has no fire rating, only the different from the time of combustion limit. Combustion performance grade A of commonly used adornment material: granite, marble, terrazzo, cement products, concrete products, gypsum, lime products, clay products, glass, ceramic tile, Mosaic, steel and alloy. I hope my answer can help you.

- Q: What are the advantages of refractory material?

- Jingute WHL type, GDS type

Send your message to us

Raw Materials for Refractory:1-3mm White Mica for Refractory Field

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords