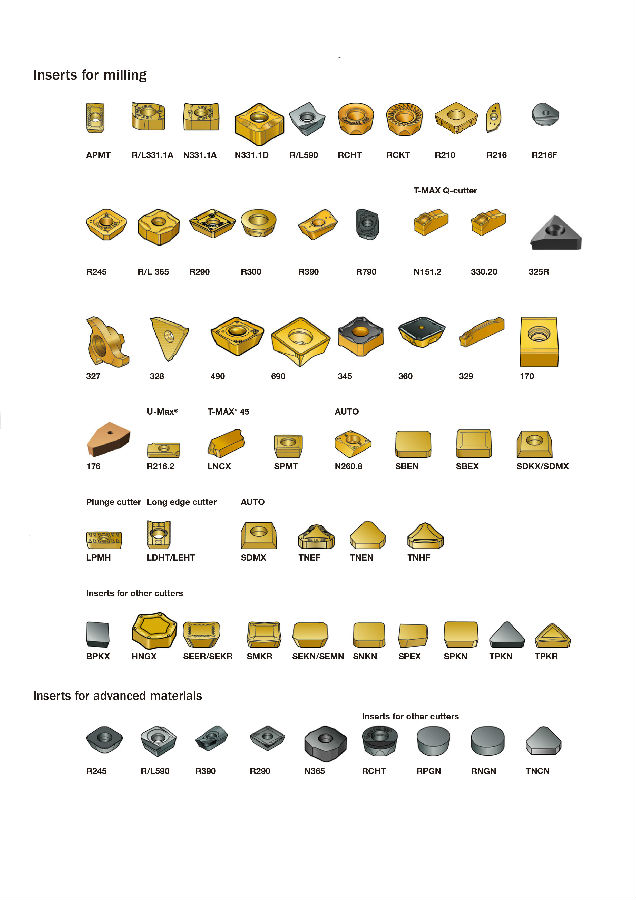

tungsten carbide inserts for cutting tool

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Information

- pure tungsten carbide material, recycling material is available

- Size of the inserts:OD limited crabide to 400 mm,thickness above 2mm

- Manufacturering carbide products including TC ball,bar material,wortle,strips,tips,dies,milling cutters,scraper blades,rods,inserts and so on.

- Factory price,manufacturing irregular shape according to your inserts' drawing

Packaging

1,soft foam to prevent the surface being scratched in one small carboard boxes, several small boxes in one larger hard carboard with fills to avoid a slope, besides hard carboard is easy to load and transport

2, we can also arrange packaging according to your special requirements or discuss

3,product code on cardboards instead of any company information such as logo to keep deal information secret and beneficial to customs clearance

Shipping

There are three ways to be choose, as follows:

- International Express: UPS,TNT,DHL

- Port transportation: all ports

- We delivery products according to customer’s requirements and paid by buyer after the destination confirmation

- take insurance for the goods according to contract

Our Service

- ISO , BV certificate and sound testing equipment to assure the quality

- Professional advice for the application problems, we accept return of goods with quality problems or discuss

- Survey Email of products usage will be sent timely to listen your feedback,our aim is trying to make everyone of our customers satified!

- Q:How to wear a car knife to the outside garden

- Howke can process the outside circle is better, a clip, can achieve the mirror effect, with the car generation grind!

- Q:Why is the blade shavings always grinding

- First, carefully before you sharpen dressing grinding wheel, cannot let the grinding wheel to produce radial and axial runout, rounded to mend the thinner, the better, if you didn't do dressing grinding wheel in this step, then hand kung fu is not likely to grind out best to meet the requirements of your knife, with 90 - degree cylindrical turning tool as an example, the first wrapped in cotton yarn, tool rod, to ensure that won't be hot in the grinding process, as long as a hot, due to the instinct of a man, your hand will consciously involuntary shiver, that also will not care so much

- Q:The welding method of lathe tool?

- Oxyacetylene flame brazing, The fire brazing High frequency brazing All brass solder or brass plate filling and borax welding

- Q:I use acetylene oxygen to weld a common lathe blade. Why does the blade keep cracking

- Welded structure of cutting tool should have enough rigidity, enough rigidity is the appearance of the maximum allowable size, and USES high strength steel grade and to ensure that the heat treatment. Carbide blade should be fixed firm, for example, cemented carbide welding blade should have enough degree of fixation, it is to rely on groove and welding quality to ensure that, generally speaking, according to the shape of blade and the cutting tool geometry parameter choice blade groove shape. It is necessary to inspect the blade before the carbide blade is welded to the blade, and the blade must be inspected first. Hard alloy welding surface must not have serious carburizing layer, at the same time should also will carbide blade surface and cutter bar set of dirt to clean, to guarantee the welding. In order to ensure the welding strength, choose the suitable solder. During the welding process, good moisture and liquidity should be guaranteed, and the bubbles shall be eliminated, and the welding and alloy welding surfaces shall be fully in contact with the welding phenomenon. Welding flux choice: borax industry, can be used in the drying furnace shall be carried out before use dehydration processing, then crushed, sieve to remove mechanical impurities in again. Use mesh compensation pads. For example: in the welding of titanium high low cobalt fine alloy and welding of long and thin blade, in order to reduce welding stress, and sheet thickness of 0.2 ~ 0.2 mm can be used or mesh aperture 2 ~ 3 mm spacer mesh compensation on welding.

- Q:Do you want to get a car knife on the tool holder

- With contrast tool rest it was just a car, probably cylindrical can, if a car not a plane or cut off, the knife has to be the center, or the tip is easy to destroy, the discretion of the head will change the knife after the anterior horn of the Angle point of view, what specific high or low will car artifacts, generally is the center, to center is very simple, you put a round steel car plane to know, and then write down center, next to quantity of a good,

- Q:The lathe tool is not moving when the thread of the CNC lathe thread

- The tooth is stopped at the beginning of the tooth because it does not find the point of the tooth. There are two reasons why you can't find a knife point: one is that your car's tooth speed is too fast, and when you find it, the main shaft turns around again. The other is that the thread head of the main shaft encoder is missing, and it is necessary to check whether the coder has a problem or a problem.

- Q:What is the main Angle of a common external turning tool?

- The Angle of the Angle, the rear Angle, the rear Angle, the Angle of the main, the Angle of the Angle, the Angle of the blade, and the Angle of the wedge. The first floor says the main Angle.

- Q:What are the types of car knives used in mechanical manufacturing?

- Ninety - degree cylindrical turning tool and cutting knife, screw knife, knife commonly used, don't know if there is hole knife, turning tool, cutting knife, internal thread cutter, as if that's all! Hey hey

- Q:How to grind a common lathe tool

- Wrought iron? The car simply tells you the point of the sharpener. A knife face cannot be ground into many faces. To grind the flat. The face (the edge of the top of the knife) is slightly higher. Not too much. Otherwise it is easy to storm. The shape of the cut depends on the number of lathes. Cutting quantity. And slot. The number of revolutions is 500 to 800. Of course, look at the artifact size. The slot is two millimeters away from the edge of the knife. Start with eight words. Can't be too shallow. I hope I can help you. You'd better buy a book.

- Q:What type of lathe tool is used for regular lathes? What is the cutting material?

- Center drill The center is drilled into the processing center hole. Has three forms: center drill, no protection of cone 60 ° composite center drill and take cone 60 ° composite center drill. The center drill is structurally similar to a twist drill. In order to save the cutter material, the compound center drill is often made into double ends. The drill trench is usually made straight. The work of the compound center consists of the borehole part and the spot. The drill is also the same as the drill, with the taper and the drill point geometry. Dimpling made 60 ° taper, protect made 120 ° taper cone. The outer circle of the working part of the composite center is inclined to be used to make sure that the transition part of the spot and the facing part and the boring part has the rear Angle.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

tungsten carbide inserts for cutting tool

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords