Carbide Turning Inserts TNMG160408 tungsten carbide inserts

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Information

- pure tungsten carbide material, recycling material is available

- Size of the inserts:OD limited crabide to 400 mm,thickness above 2mm

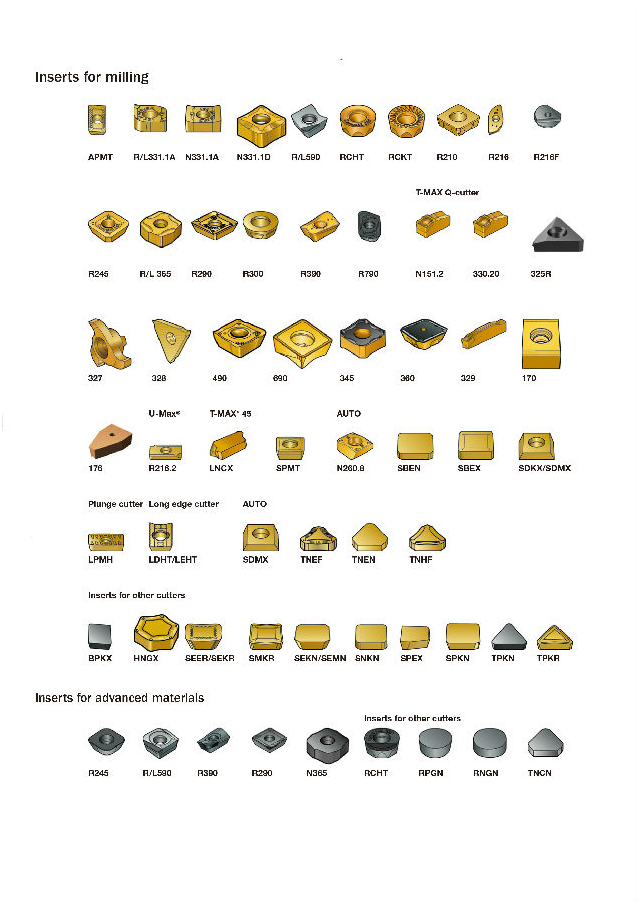

- Manufacturering carbide products including TC ball,bar material,wortle,strips,tips,dies,milling cutters,scraper blades,rods,inserts and so on.

- Factory price,manufacturing irregular shape according to your inserts' drawing

Packaging

- soft foam to prevent the surface being scratched in one small carboard boxes, several small boxes in one larger hard carboard with fills to avoid a slope, besides hard carboard is easy to load and transport

- we can also arrange packaging according to your special requirements or discuss

product code on cardboards instead of any company information such as logo to keep deal information secret and beneficial to customs clearance

Shipping

There are three ways to be choose, as follows:

- International Express: UPS,TNT,DHL

- Port transportation: all ports

- We delivery products according to customer’s requirements and paid by buyer after the destination confirmation

- take insurance for the goods according to contract

Our Service

- ISO , BV certificate and sound testing equipment to assure the quality

- Professional advice for the application problems, we accept return of goods with quality problems or discuss

- Survey Email of products usage will be sent timely to listen your feedback,our aim is trying to make everyone of our customers satified!

- Q:I want to know what materials I need to weld a carbide-tipped tool

- You need to use the alloy electrode and 唖 welding tool Objects will first heated to red state (temperature of about 800 ~ 1000 degrees) and electrode with borax as flux (add) in accordance with the necessary then cemented carbide and tungsten steel lathe tool welding on the tool holder to complete a turning lathe turning tool rack can be attached cutting machine processing work

- Q:There are several kinds of lathe knives for regular lathes

- Carbide welding lathe tool A welding tool, is on the carbon steel cutter bar open groove, according to the requirement of the cutting tool geometry Angle solder will carbide blade welding in the tank, and according to the selected tool geometric parameters used after grinding.

- Q:What is different about the shape of the external turning tool and the inner circle tool?

- However, if the inner circle is large and the depth of the hole is reached into the hole with a knife stick, it will also be done with a common knife. I always feel that the internal round car knife is not rigid.

- Q:How do you know the type of car knife

- Pointed tool. A car knife characterized by a straight-line cutting knife is commonly referred to as a pointed car knife. This kind of lathe tool tip is composed of rectilinear Lord, vice cutting edges, machining parts, the part contour shape is mainly composed of a separate point or a straight line shape, resulting from the displacement of the main cutting edge and the other two kinds of cutting tool machining by the principle of parts contour shape is very different. Such as 90. Inside and outside the circular turning tool, the left and right side of the vehicle knife, cut off (car slot) the car knife and the blade of the tip of the knife the various outer circles and the inner hole tool.

- Q:Can the welding tool be welded with 2.5 copper wire

- The welding tool can be used for 2.5 copper wires (s221 wire). Lathe using cutting tool head, belong to the hard alloy steel, such as YG8, YT15, YW1 etc., and the blade carbon steel with copper welding method, the most common is the copper brazing.

- Q:How do you divide the main cutting edge of the blade after the main of the tool?

- The main cutting edge of the cutting edge is in the line of space with the rear edge of the main blade. (2) the intersection of the front edge of the cutting edge and the side of the knife face in space. (3) the tip of the knife is at the intersection of space, but it also can be understood as a small cutting edge of the two blades. In practical application, the transition blade of a straight line or circular arc is worn at the tip of the knife to increase the strength and abrasion of the tip.

- Q:The effect of the Angle on cutting machining.

- The main deflection affects the shape of the cutting layer, the length of the cutting edge and the load on the unit cutting edge. Decrease kappa r predominate, the main cutting edge load per unit length decreases, tool wear is small, improved durability, make machined surface roughness decrease. Smaller main Angle is easy to form long and continuous spiral crumbs, does not favor the chip breaker, so automated processing of chip control strictly, YiQu larger primary Angle. The influence and selection of the auxiliary Angle on processing

- Q:What is the powder of the car knife welding

- Called flux. Flux (flux) : a chemical that helps and facilitates welding during welding process and has protective effect and prevents oxidation. The flux can be divided into solids, liquids and gases. "Main auxiliary heat transfer", "removal of oxide", "reducing the welding material surface tension", "remove welding material surface oil pollution, increase welding area", "to prevent oxidation" and so on several aspects, more critical role in these aspects, there are two is: "to remove the oxide" and "reduce the welding material surface tension". role The main active ingredient in the flux is rosin, which is broken down by tin at about 260 degrees Celsius, so the temperature of the tin slot is not too high. The flux is a chemical that promotes welding. In soldering tin, it is an indispensable auxiliary material which is extremely important.

- Q:How do you solve the blade with a knife blade

- Not the machine tool ask, this is the knife phenomenon that the processing time, is objective existence

- Q:The effect and durability of the golden coating of the tool

- Golden is coating There is hard alloy Is titanium plating coating If the coating wear down the life of the cutting head is not long He is same with the cutting head without coating And in order to increase the life of the knife you will have a great change in the coolant when you use it

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbide Turning Inserts TNMG160408 tungsten carbide inserts

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords